A method for grouping and separating yttrium oxide from high-yttrium-type rare earth ores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

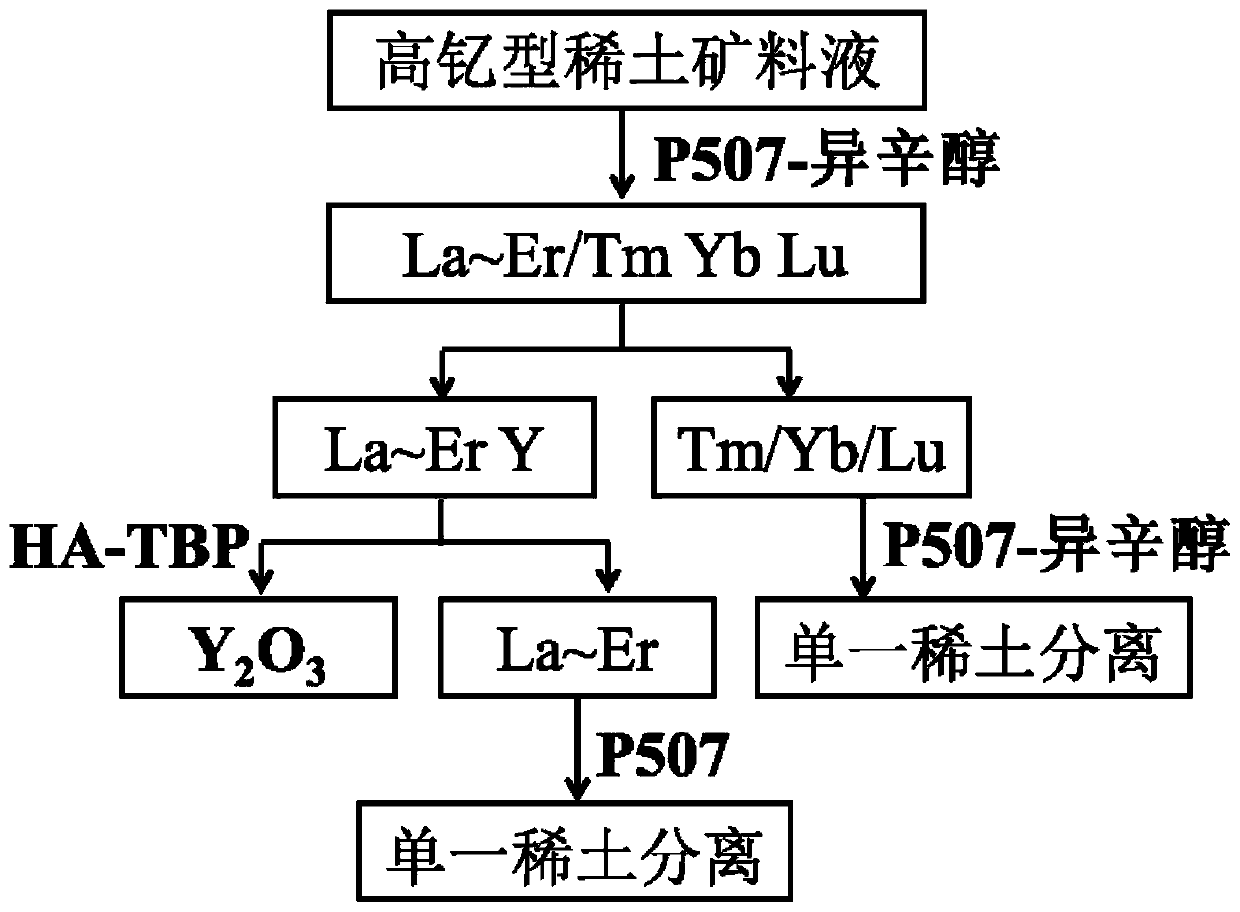

[0046] Step 1: The high-yttrium type rare earth ore liquid is grouped with erbium and thulium in a 1.0mol / L P507-20% isooctyl alcohol mixed system, and the degree of saponification is 36%. The organic phase is back-extracted with 5mol / L hydrochloric acid, and the raffinate aqueous phase is La ~Er Y component (yttrium-rich material), the organic phase is TmYb Lu component (thulium ytterbium lutetium enrichment). Thulium, ytterbium and lutetium concentrates are separated by a 1.0mol / L P507-20% isooctyl alcohol mixed system to separate a single heavy rare earth, and 5N lutetium oxide, 3N thulium oxide, and 5N ytterbium oxide can be obtained.

[0047] Step 2: The yttrium-rich feed solution is directly extracted and separated from yttrium oxide with a 0.50mol / L CA12-10%TBP mixed system, the degree of saponification is 80%, the organic phase is back-extracted with 3mol / L hydrochloric acid, and the raffinate aqueous phase is the Y component. The organic phase is La-Er components, and...

Embodiment 2

[0050] Step 1: The high yttrium-type rare earth ore liquid is grouped with 0.5mol / L P507-0.5mol / L Cyanex272 mixed system erbium and thulium, the degree of saponification is 36%, the organic phase is back-extracted with 3.5mol / L hydrochloric acid, and the raffinate aqueous phase is La~Er Y component (yttrium-rich material), the organic phase is Tm Yb Lu component (thulium, ytterbium and lutetium enrichment). Thulium, ytterbium and lutetium concentrates are separated by a 0.5mol / L P507-0.5mol / L Cyanex272 mixed system to separate single heavy rare earths, and 4N lutetium oxide, 4N thulium oxide, and 4N ytterbium oxide can be obtained.

[0051] Step 2: Use 0.8mol / L CA12-20% TBP mixed system to directly extract and separate yttrium oxide from the yttrium-rich feed solution, the degree of saponification is 90%, the organic phase is back-extracted with 3.0mol / L hydrochloric acid, and the raffinate aqueous phase is the Y component , the organic phase is La-Er components, and the raffi...

Embodiment 3

[0054] Step 1: The high-yttrium type rare earth ore liquid is grouped with 0.5mol / L P507-0.5mol / L P227 mixed system erbium and thulium, the degree of saponification is 36%, the organic phase is back-extracted with 3mol / L hydrochloric acid, and the raffinate aqueous phase is La ~Er Y component (yttrium-rich material), the organic phase is Tm Yb Lu component (thulium ytterbium lutetium enrichment). The thulium, ytterbium and lutetium concentrates are separated by a 0.5mol / L P507-0.5mol / L P227 mixed system to separate a single heavy rare earth, and 5N lutetium oxide, 4N thulium oxide, and 4N ytterbium oxide can be obtained.

[0055] Step 2: Use 0.8mol / L CA100-20% TBP mixed system to directly extract and separate yttrium oxide from the yttrium-rich feed solution, the degree of saponification is 90%, the organic phase is back-extracted with 3.0mol / L hydrochloric acid, and the raffinate aqueous phase is the Y component , the organic phase is La-Er components, and the raffinate aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com