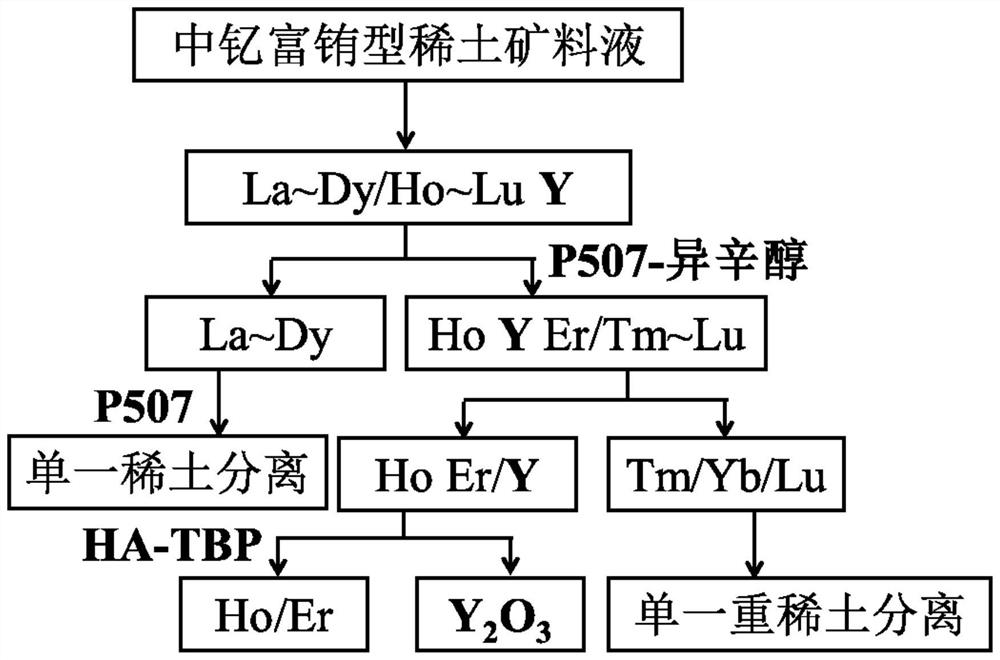

A method for grouping and separating yttrium oxide from middle yttrium and europium-rich rare earth ores

A technology of rare earth ore and europium-rich type, which is applied in the preparation/treatment of rare earth metal oxides/hydroxides, rare earth metal compounds, yttrium oxide/yttrium hydroxide, etc., which can solve separation difficulties, affect process stability, and lanthanum Problems such as small yttrium separation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Step 1: The medium yttrium europium-rich rare earth mineral material is divided into groups with 1.0mol / L P507-20% isooctanol mixed system dysprosium and holmium, the saponification degree is 36%, the organic phase is back-extracted with 5mol / L hydrochloric acid, and the raffinate water phase It is light and medium rare earth enrichment (La~Dy component), and the organic phase is yttrium-rich material 1 (Ho~Lu Y component), Y 2 O 3 The grade is about 83%. The light and medium rare earth enrichment is separated by a 1.5mol / LP507 system to separate a single rare earth, the saponification degree is 36%, and the organic phase is stripped with 3.5mol / L hydrochloric acid.

[0049] Step 2: Yttrium-rich material 1 is grouped with 1.2mol / L P507-20% isooctyl alcohol mixed system erbium-thulium, and the raffinate water phase is yttrium-rich material 2 (Ho Er Y component), Y 2 O 3 The grade increased to 88%. The organic phase is the thulium-ytterbium-lutetium-enriched product, and the...

Embodiment 2

[0052] Step 1: The medium yttrium europium-rich rare earth mineral material is divided into groups with 0.5mol / L P507-0.5mol / L Cyanex272 mixed system dysprosium and holmium, the saponification degree is 36%, the organic phase is stripped with 3.5mol / L hydrochloric acid, and the raffinate water The phase is light and medium rare earth enrichment (La~Dy component), the organic phase is yttrium-rich material 1 (Ho~Lu Y component), Y 2 O 3 The grade is about 83%. A 1.0mol / L P507 system was used to separate a single rare earth in the light and medium rare earth enrichment, the saponification degree was 36%, and the organic phase was back-extracted with 3.0mol / L hydrochloric acid.

[0053] Step 2: Yttrium-rich material 1 is divided into groups with 0.5mol / L P507-0.5mol / L Cyanex272 mixed system erbium-thulium, and the raffinate water phase is yttrium-rich material 2 (Ho Er Y component), Y 2 O 3 The grade increased to 88%. The organic phase is the thulium, ytterbium, and lutetium enrichm...

Embodiment 3

[0056] Step 1: The medium yttrium europium-rich rare earth mineral material is divided into groups with 0.5mol / L P507-0.5mol / L P227 mixed system dysprosium and holmium, the saponification degree is 36%, the organic phase is back-extracted with 3mol / L hydrochloric acid, and the raffinate water phase It is light and medium rare earth enrichment (La~Dy component), and the organic phase is yttrium-rich material 1 (Ho~Lu Y component), Y 2 O 3 The grade is about 83%. The light and medium rare earth enrichment adopts 1.2mol / LP507 system to separate single rare earth, the saponification degree is 36%, and the organic phase is stripped with 3.5mol / L hydrochloric acid.

[0057] Step 2: Yttrium-rich material 1 is divided into groups with 0.5mol / L P507-0.5mol / L P227 mixed system erbium-thulium, and the raffinate water phase is yttrium-rich material 2 (Ho Er Y component), Y 2 O 3 The grade is increased to 88%, the organic phase is the thulium-ytterbium-lutetium-enriched material, and the strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com