Preparation method of high polymer material special for cosmetic brush packaging

A technology for polymer materials and cosmetic pencils, applied in the field of polymer materials, can solve the problems of uneven dynamic friction, unstable static friction, easy product wear, etc., achieve long-term stability, ensure surface activity, and reduce the effect of material specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

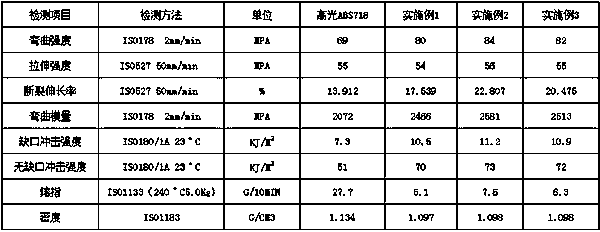

Examples

Embodiment 1

[0026] A method for preparing a special polymer material for cosmetic pencil packaging, comprising the steps of:

[0027] (1) Preparation of raw materials: In parts by weight, it includes 75 parts of acrylonitrile-butadiene-styrene plastic, 10 parts of polycarbonate, 1 part of liquid dispersant, 1 part of compatibilizer, 1 part of solid dispersant, lubricating 5 parts of agent, 1 part of black powder;

[0028] (2) After drying the acrylonitrile-butadiene-styrene plastic and polycarbonate at 90~100℃ for 3~4 hours, set aside;

[0029] (3) Add the raw materials sequentially and blend evenly, mix them in a high-speed mixer for 10-15 minutes, then send them to a twin-screw extruder for full plasticization and blending, extrude, cool, granulate, and dry to obtain polymers Material.

[0030] Among them, the acrylonitrile-butadiene-styrene plastic used uses plate-grade materials to provide mechanical support and alleviate the mechanical decline caused by multi-components. The specif...

Embodiment 2

[0041] The difference from Example 1 is that this example provides a method for preparing a special polymer material for cosmetic pencil packaging, including the following steps:

[0042] (1) Preparation of raw materials: In parts by weight, it includes 79 parts of acrylonitrile-butadiene-styrene plastic, 14 parts of polycarbonate, 1.5 parts of liquid dispersant, 2.2 parts of compatibilizer, 2.1 parts of solid dispersant, lubricating 7.4 parts of agent, 1 part of black powder;

[0043] (2) After drying the acrylonitrile-butadiene-styrene plastic and polycarbonate at 90~100℃ for 3~4 hours, set aside;

[0044] (3) Add the raw materials in order and blend them evenly, mix them in a high-speed mixer for 10-15 minutes, then send them to a twin-screw extruder for full plasticization and blending, extrude, cool, granulate, and dry to obtain polymers Material.

[0045] Specifically, the silicone powder and polytetrafluoroethylene are 4.1 parts by weight of silicone powder and 3.3 pa...

Embodiment 3

[0047] The difference from Example 1 is that this example provides a method for preparing a special polymer material for cosmetic pencil packaging, including the following steps:

[0048] (1) Preparation of raw materials: In parts by weight, it includes 85 parts of acrylonitrile-butadiene-styrene plastic, 20 parts of polycarbonate, 3 parts of liquid dispersant, 5 parts of compatibilizer, 5 parts of solid dispersant, lubricating 10 parts of agent, 1 part of black powder;

[0049] (2) After drying the acrylonitrile-butadiene-styrene plastic and polycarbonate at 90~100℃ for 3~4 hours, set aside;

[0050] (3) Add the raw materials in order and blend them evenly, mix them in a high-speed mixer for 10-15 minutes, then send them to a twin-screw extruder for full plasticization and blending, extrude, cool, granulate, and dry to obtain polymers Material.

[0051] Specifically, the silicone powder and polytetrafluoroethylene are 5 parts by weight of silicone powder and 5 parts of poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com