Ferrite-series stainless steeel cold-rolled steel plate and manufacturing method thereof

A technology of cold-rolled steel plate and manufacturing method, which is applied in the field of ferritic stainless steel cold-rolled steel plate and its manufacture, and can solve the problems such as the reduction of the appearance of the steel plate surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

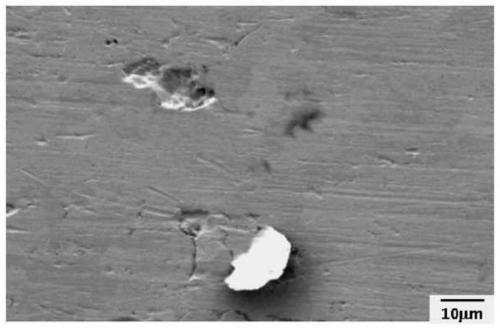

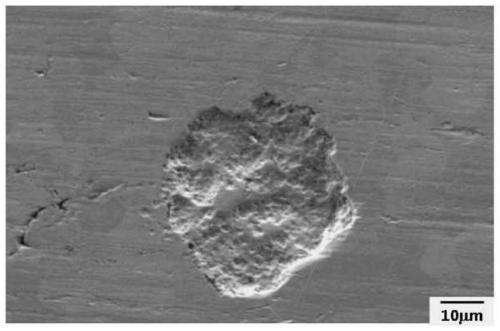

Image

Examples

Embodiment

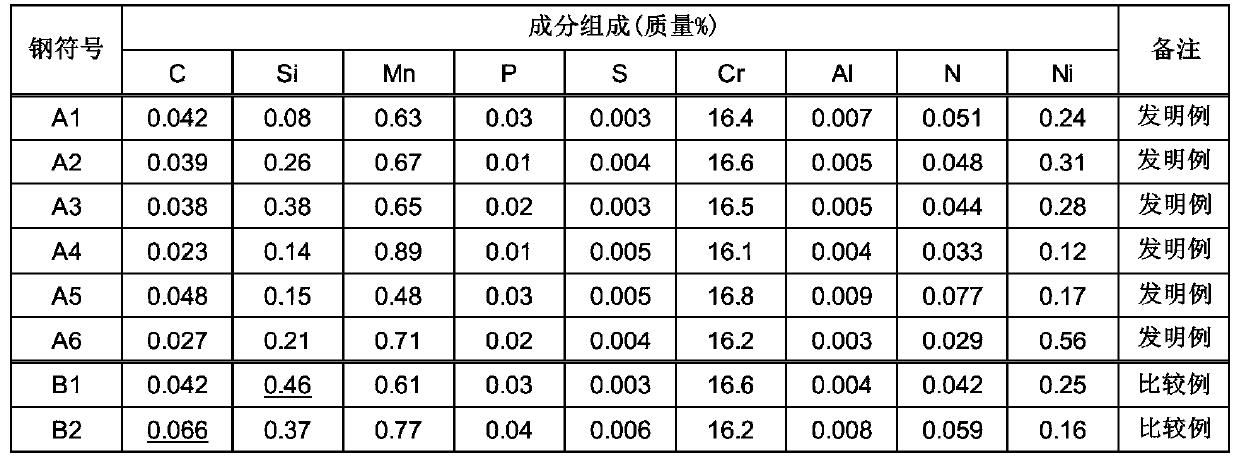

[0166] Molten steel with the composition shown in Table 1 (the balance is Fe and unavoidable impurities) was smelted by refining using a converter with a capacity of 150 tons and a vacuum oxygen decarburization (VOD) method, and then, by continuous Casting is made into a billet with a width of 1000 mm and a thickness of 200 mm.

[0167] After heating this billet at 1200° C. for 1 hour, seven passes of rough rolling using a reversing rolling mill consisting of three stands and seven passes of rough rolling using a one-way rolling mill consisting of seven stands were carried out. The finish rolling of the substructure is hot rolling, and a coiling treatment is performed at about 750° C. to obtain a hot-rolled steel sheet having a thickness of about 5.0 mm.

[0168] Next, these hot-rolled steel sheets were subjected to hot-rolled sheet annealing using a box annealing method under the conditions shown in Table 2 to produce hot-rolled annealed steel sheets, and then the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com