Stable cleaning fluid used after chemical-mechanical polishing, and preparation method and application thereof

A cleaning solution and dismutase technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor copper-based chips, and achieve broad market application prospects, good selectivity, and anti-corrosion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In the following examples and comparative examples, the preparation method of the cleaning solution includes the following steps: mixing the raw materials. Said mixing usually involves adding the solid components of said raw material components into the liquid components and stirring evenly. The mixing temperature is room temperature. After the mixing, operations of shaking and filtering are also included. The purpose of the oscillation is to fully mix the raw material components, and the oscillation speed and time are not limited.

[0035] The reagents and raw materials used in the following examples and comparative examples are all commercially available.

[0036] In the following examples, those that do not limit the specific operating temperature all refer to carrying out at room temperature.

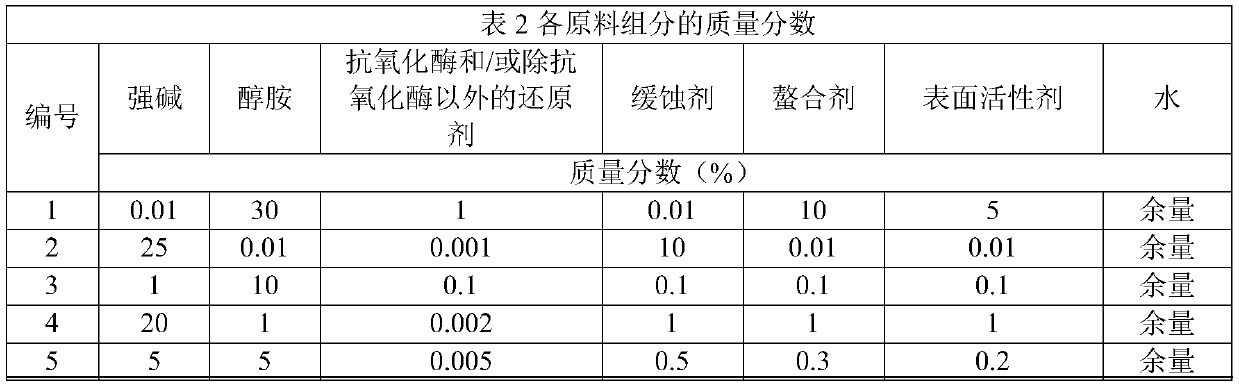

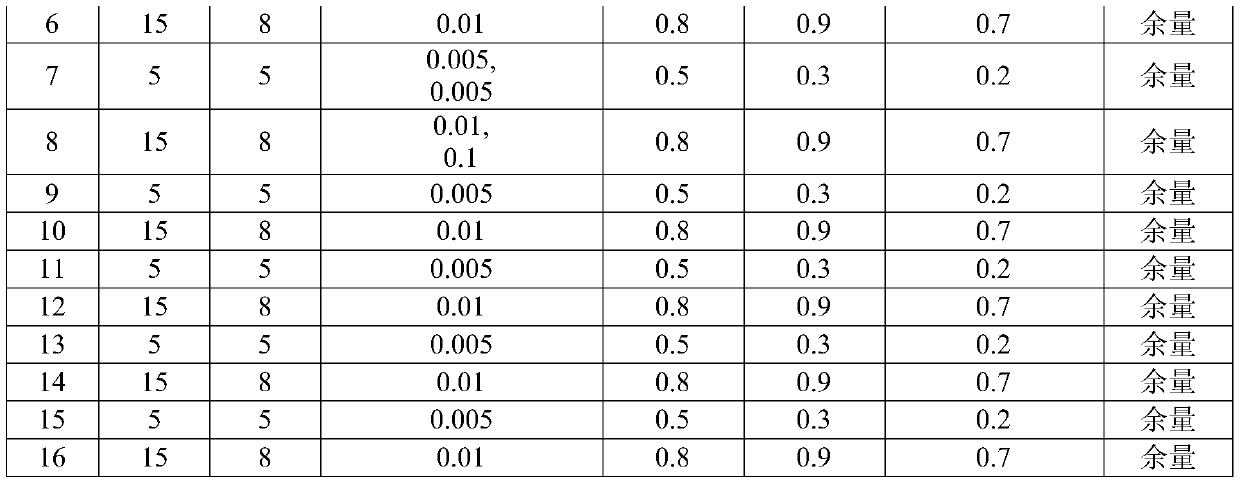

Embodiment 1-16

[0038]

[0039]

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com