Rodent control and isolation ditching and net burying device

A ditch burial and rodent damage technology, which is applied to earth movers/excavators, construction, etc., can solve the problems of grassland ecological environment hazards, unfavorable water and soil, and easy water and soil loss, so as to prevent and control rodent damage, save manpower and material resources, The effect of simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

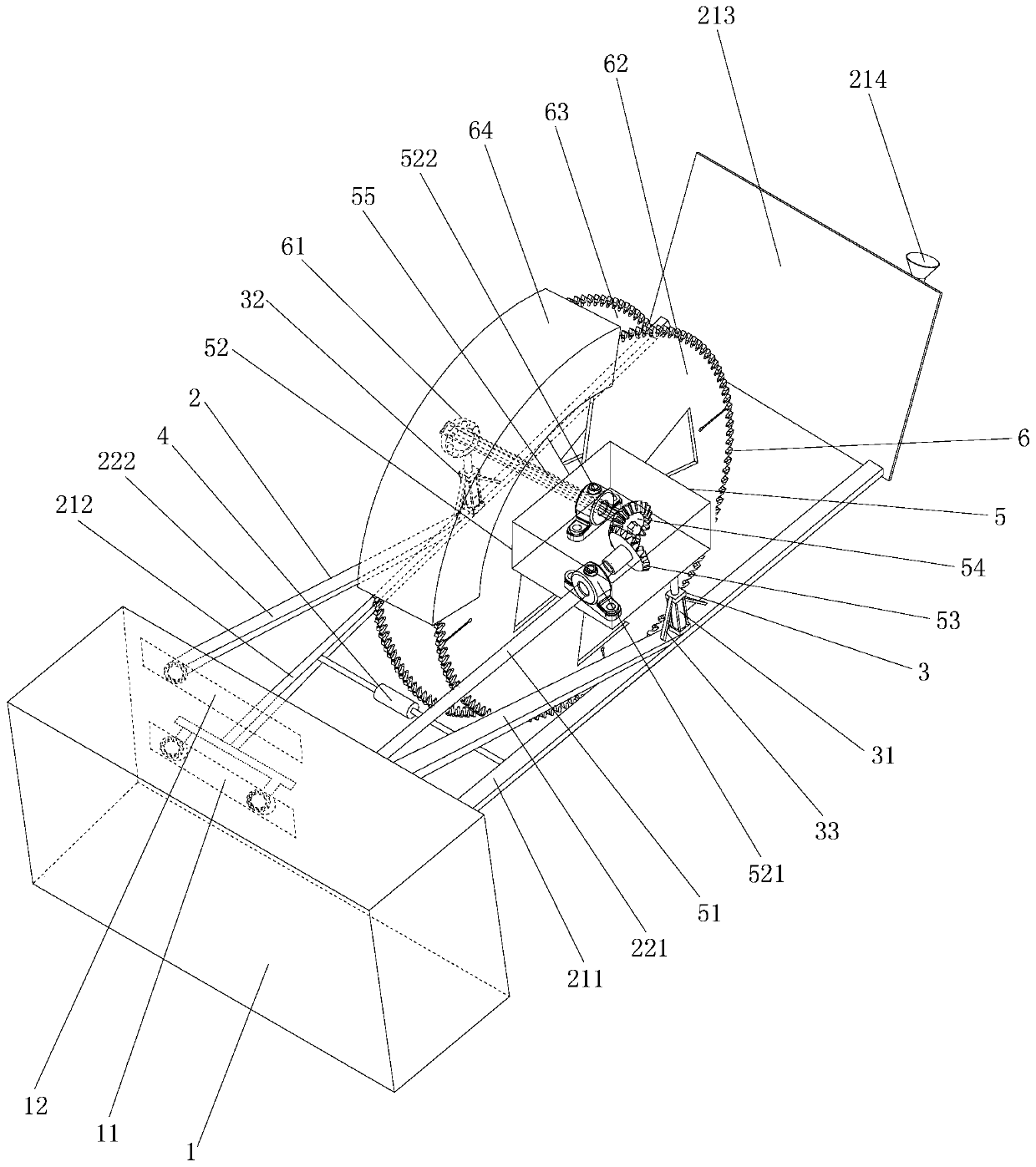

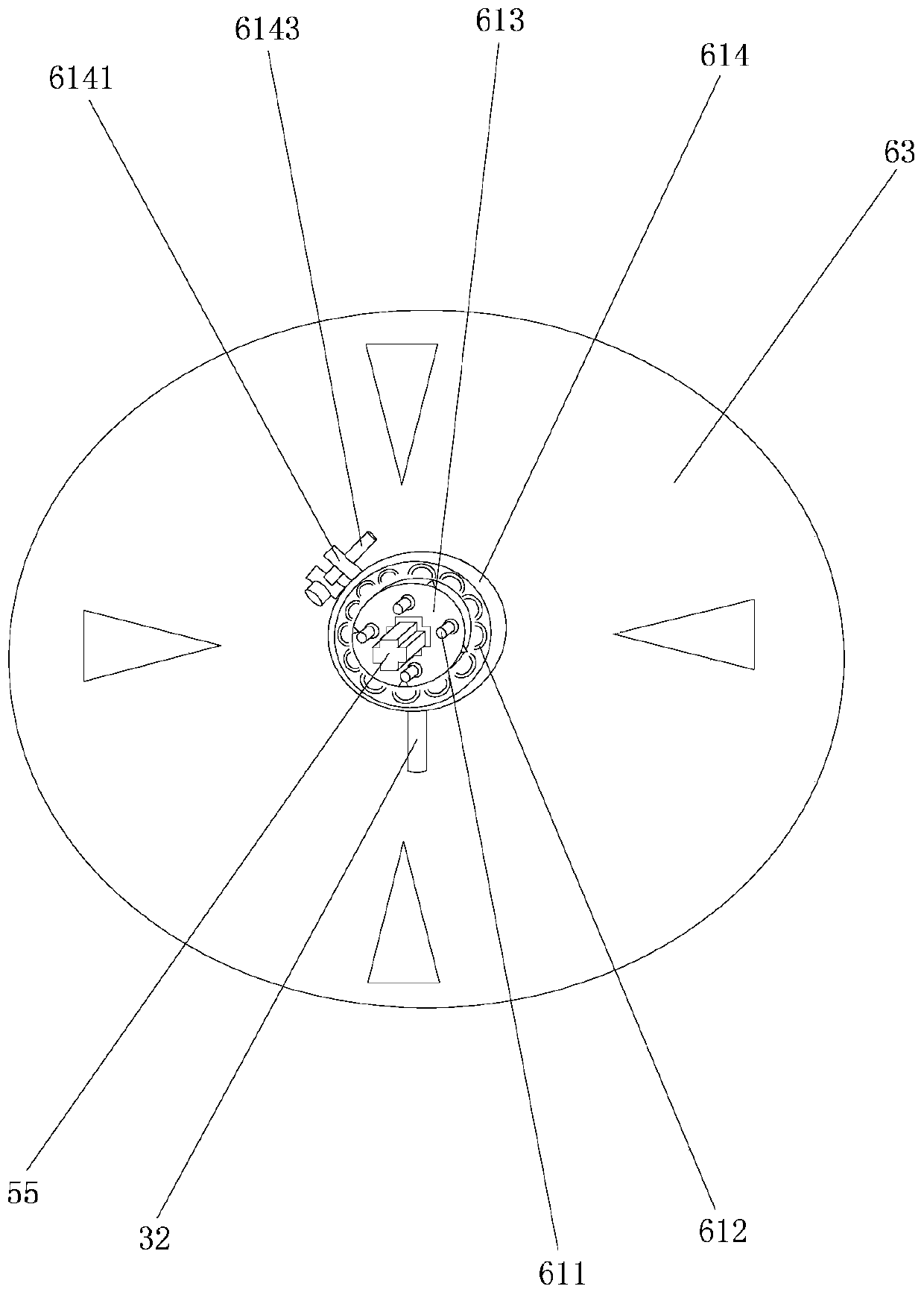

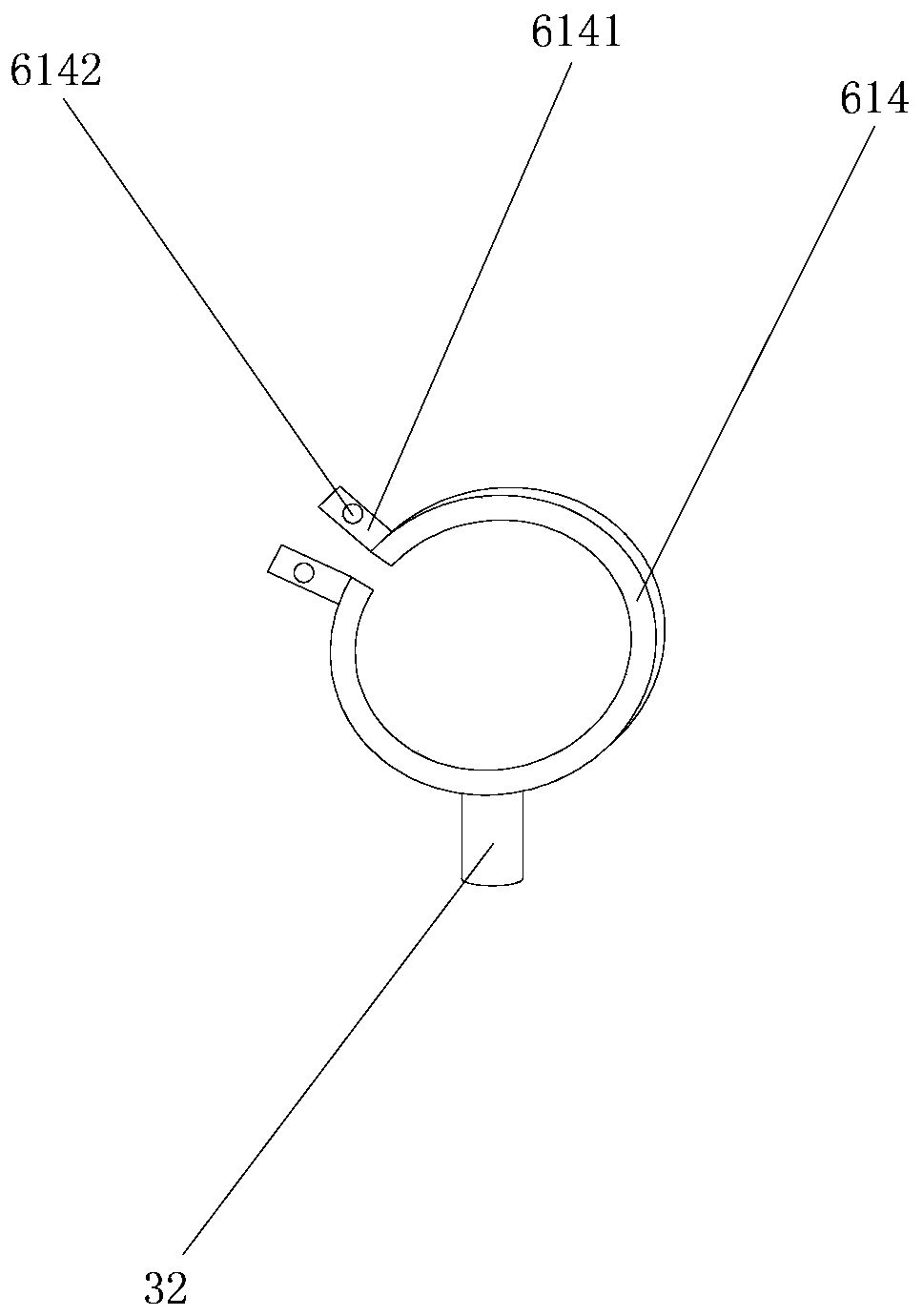

[0032] Such as figure 1 As shown, the rodent pest prevention and isolation ditching net embedding device of the present invention includes a traction device 1 , a fixed frame 2 , a height adjustment hydraulic device 3 , a width adjustment hydraulic device 4 , a transmission mechanism 5 and a slice assembly 6 .

[0033] The traction device 1 adopts a tractor, which is provided with a slicing driving device and a hydraulic system; wherein, the front or rear of the traction device 1 is provided with a support frame chute 11 and a fixed pull rod chute 12 along the horizontal direction; the fixed pull rod slides The groove 12 is located on the upper side of the sliding groove 11 of the support frame.

[0034] The fixed frame 2 is installed on one side of the traction device 1 , one side is a movable support that is movably connected to the traction device 1 , and the other side is a fixed support that is fixedly connected to the traction device 1 . The fixing frame 2 includes a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com