High-pressure reciprocating sealing structure

A sealing structure and high-pressure technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of reliability, pressurization and pressure-holding performance gap, etc., and achieve the effect of low friction, zero leakage and reliable sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

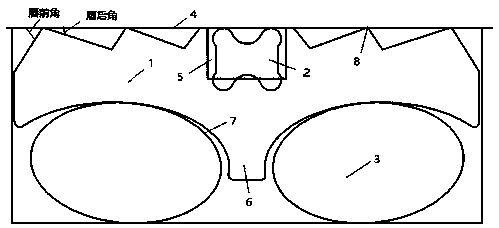

[0027] The invention discloses a high-pressure reciprocating sealing structure, including:

[0028] Sealing ring 1, said sealing ring 1 is a polytetrafluoroethylene composite material added with relevant additives, and has an ultra-low coefficient of friction. The seal ring 1 has a left-right symmetrical structure, and the middle part of one side in contact with the oil cylinder mating surface 4 has a middle groove 5, and the other side has a sealing bottom 6 at a position opposite to the middle groove 5. The left and right sides of the sealing bottom 6 are symmetrically provided with sealing grooves 7; the X-shaped sealing ring 2 is installed in the middle groove 5, and the O-shaped sealing ring 3 is symmetrically installed in the sealing groove 7 Inside; the sealing ring 1 is located on both sides of the middle groove 5 with symmetrically distributed sealing lips 8, and the sealing lips 8 are in contact with the oil cylinder mating surface 4 in a platform structure with a le...

Embodiment 2

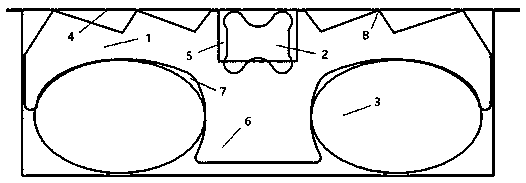

[0042] The difference from Example 1 is that the width of the sealing bottom 6 is greater than the width of the middle groove 5; the distance from the top of the sealing groove 5 to the middle of the lower edge of the sealing bottom 6 is the O-shaped 2 / 3~1 times of the diameter of the sealing ring 3 . Through the structural design of the sealing bottom 6 on the sealing ring 1, it can provide good rear support for the O-ring 3 during the dynamic sealing process, prolonging the service life of the O-ring 3; the sealing grooves 7 on both sides can be the first The road seal provides greater support and improves sealing performance. Two sides of the bottom of the sealing bottom 6 extend toward the sealing groove 7 .

Embodiment 3

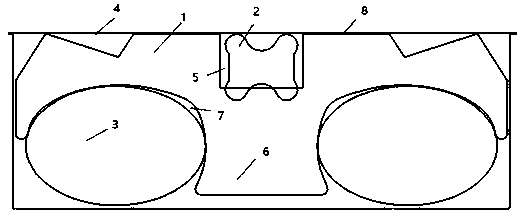

[0044] The difference from Example 2 is that the sealing ring 1 and the oil cylinder mating surface 4 have 4 seals, and one side has 2 seals. After the sealing fluid passes through the second sealing gap, an obvious throttling effect is produced, and the sealing pressure drops rapidly. , Low-pressure fluid is more likely to be sealed through the X-shaped sealing ring, and the sealing performance is good. This embodiment has simple structure, low processing cost, high structural strength, and low risk of fatigue failure after working for a long time.

[0045] The present invention has following beneficial effect:

[0046] 1. The sealing ring is sealed by a multi-stage labyrinth, which can effectively reduce the oil pressure and leakage. The design of the front lip angle is much larger than the rear lip angle, so that the pressure gradient near the front lip angle is greater than the pressure gradient of the lip rear angle, which is conducive to reciprocating movement The anti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com