Device and method for treating hydrogen-containing purge gas by low-temperature catalytic oxidation

A technology of oxidation treatment and low-temperature catalysis, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve problems such as poor safety, and achieve the effects of preventing safety problems, good technical effects, safe and reliable control and operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

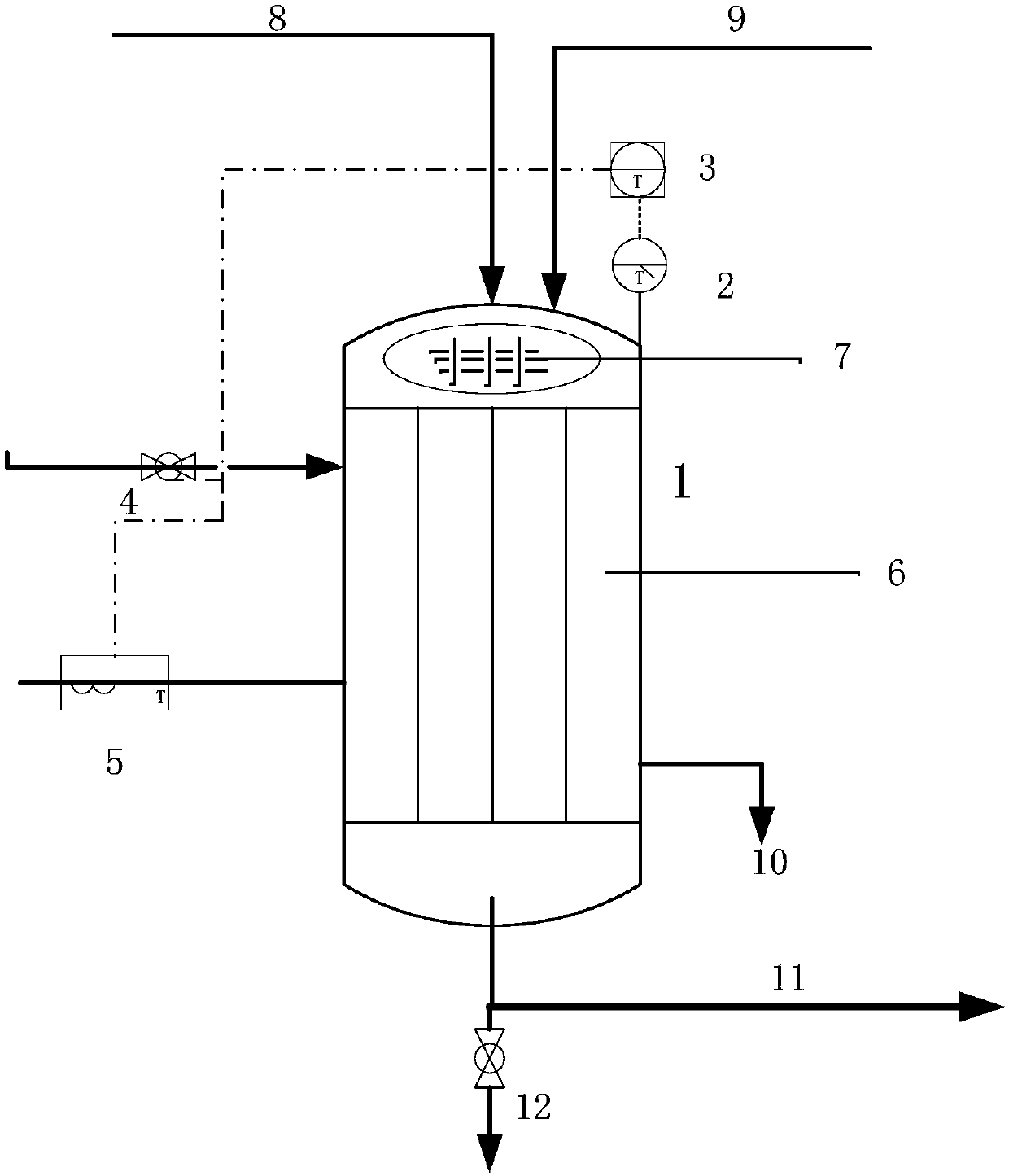

[0019] A method for low-temperature catalytic oxidation treatment of hydrogen-containing purge gas, such as figure 1 As shown, the hydrogen-containing purge gas and air enter the tubular catalytic oxidation reactor, contact with the catalyst, and a non-combustion oxidation reaction occurs, the reacted gas is discharged through the discharge line, and the generated water is discharged from the condensation discharge line; the tubular The type catalytic oxidation reactor is equipped with a heating and temperature control system, and a fire-resistant wire mesh is installed on the top. The catalyst is platinum metal powder, and the catalyst is packed in a column tube.

[0020] A small amount of hydrogenation tail gas discharged from the hydrogenation reaction system enters from the top of the reactor. Under the action of the platinum catalyst, hydrogen and oxygen in the air rapidly undergo a non-combustion oxidation reaction to generate water and discharge from the bottom. The cat...

Embodiment 2

[0023] A method for low-temperature catalytic oxidation treatment of hydrogen-containing purge gas, such as figure 1 As shown, the hydrogen-containing purge gas and air enter the tubular catalytic oxidation reactor, contact with the catalyst, and a non-combustion oxidation reaction occurs, the reacted gas is discharged through the discharge line, and the generated water is discharged from the condensation discharge line; the tubular The type catalytic oxidation reactor is equipped with a heating and temperature control system, and a fire-resistant wire mesh is installed at the bottom. The catalyst is palladium metal powder, and the catalyst is packed in a column tube.

[0024] A small amount of hydrogenation tail gas discharged from the hydrogenation reaction system enters from the bottom of the reactor. Under the action of the palladium catalyst, hydrogen and oxygen in the air rapidly undergo a non-combustion oxidation reaction to generate water and discharge from the bottom. ...

Embodiment 3

[0027] A method for low-temperature catalytic oxidation treatment of hydrogen-containing purge gas, such as figure 1 As shown, the hydrogen-containing purge gas and air enter the tubular catalytic oxidation reactor, contact with the catalyst, and a non-combustion oxidation reaction occurs, the reacted gas is discharged through the discharge line, and the generated water is discharged from the condensation discharge line; the tubular The type catalytic oxidation reactor is equipped with a heating and temperature control system, and a fire-resistant wire mesh is installed on the top. The catalyst is a platinum wire mesh, and the catalyst is packed in a column tube.

[0028] A small amount of hydrogenation tail gas discharged from the hydrogenation reaction system enters from the top of the reactor. Under the action of the platinum catalyst, hydrogen and oxygen in the air rapidly undergo a non-combustion oxidation reaction to generate water and discharge from the bottom. The cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com