Wine distillation device

A technology of a wine steaming device and a heating device, which is applied in the preparation of alcoholic beverages, etc., which can solve the problems of poor sanitary conditions, substandard sanitation, and large occupied area, and achieve the effects of not being easy to corrode and pollute, reducing labor intensity, and conveniently discharging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

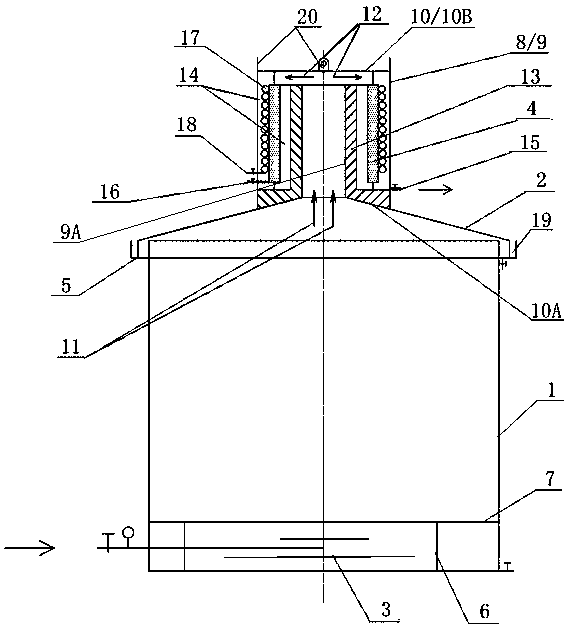

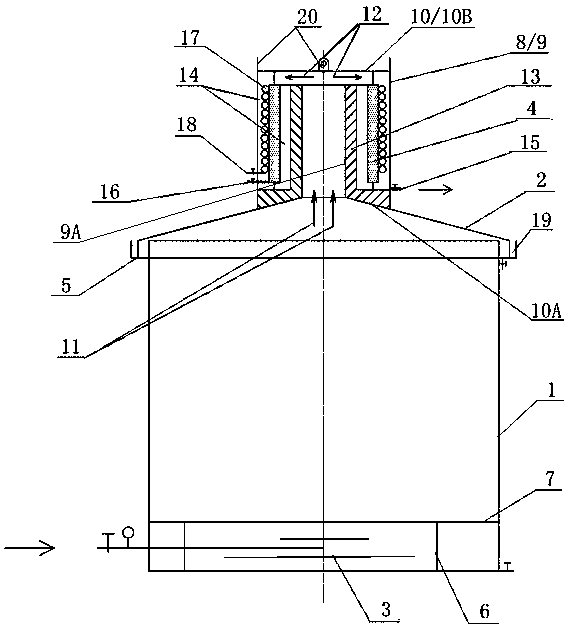

[0028] The present invention as figure 1 Shown:

[0029] A device for distilling wine, comprising a distillation barrel 1, a barrel cover 2 is provided on the top of the distillation barrel 1, a sealing device is provided at the contact ring between the barrel cover and the distillation barrel, and a sealing device is provided at the contact ring between the barrel cover 2 and the distillation barrel 1 Device 5, the top of the barrel cover 2 is provided with a wine steam outlet, the bottom of the distilling barrel 1 is provided with a drain hole, a drain pipe is installed on the drain hole, and a valve is installed on the drain pipe; the wine steaming device also includes a heating device 3 and Condensing device 4;

[0030] A bracket 6 is placed on the inner bottom of the distillation barrel 1, and a sieve plate 7 is supported on the bracket 6. The sieve plate 7 divides the distillation barrel 1 into an upper wine grains accommodation cavity and a lower heating function cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com