A biomedical magnesium alloy with high corrosion resistance and uniform degradation and preparation method thereof

A biomedical and magnesium alloy technology, applied in the field of biomedical magnesium alloys, can solve problems such as unclear toxic and side effects, achieve broad clinical application prospects, easy industrial mass production, and improve biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

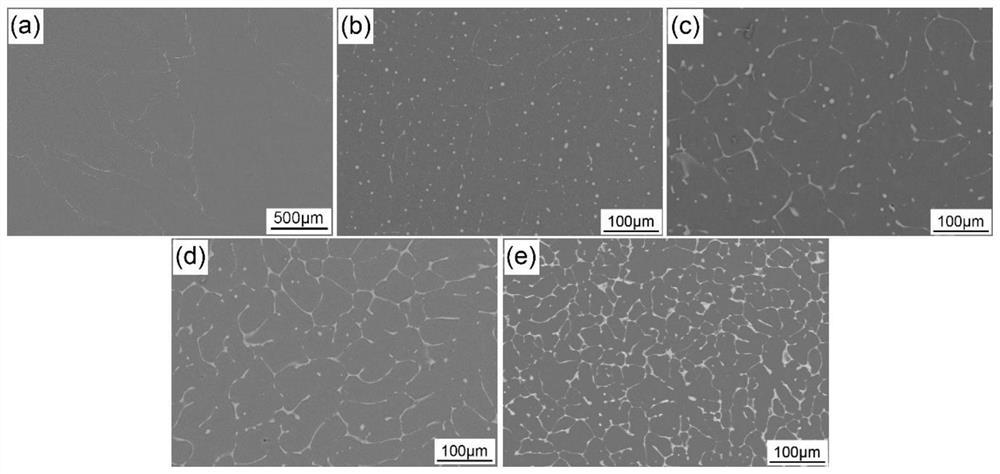

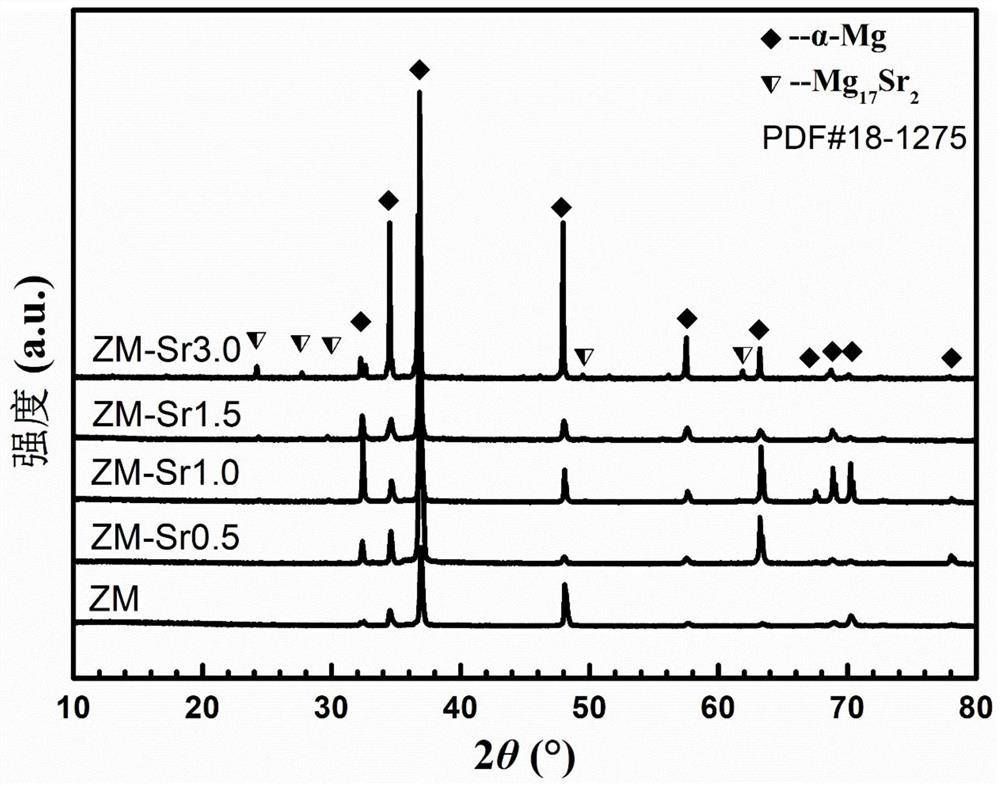

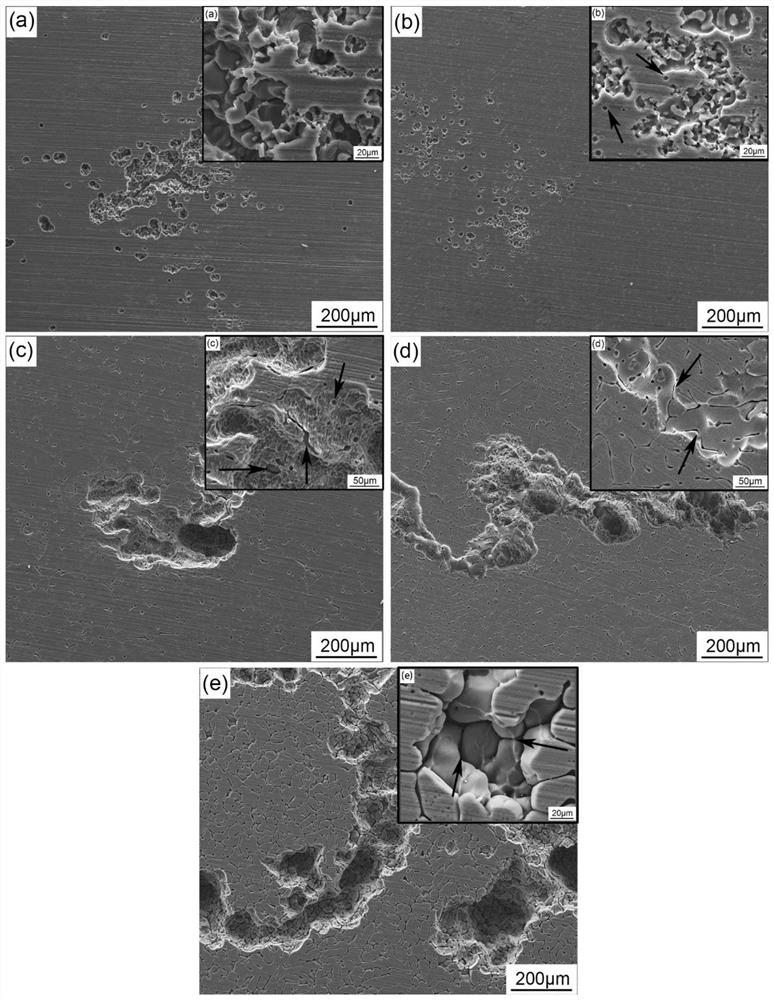

[0034] A method for preparing a magnesium alloy, comprising the steps of:

[0035] (1) Weigh raw material pure Mg (99.99%), pure Zn (99.99%), pure Mn (99.99%) according to the ratio of Mg:Zn:Mn=98:1:1;

[0036] (2) Put pure magnesium and other materials together in a graphite crucible, heat the resistance furnace to 760°C to melt all raw materials, and keep stirring, stop heating and let stand;

[0037] (3) After smelting, pour the melt into a steel mold preheated to 200°C, and finally cool it completely to obtain a Mg-Zn-Mn-Sr quaternary alloy;

[0038] The entire smelting process is carried out in CO 2 (99.5%) and SF 6 (0.5%) in a mixed protective gas.

Embodiment 2

[0040] A method for preparing a magnesium alloy, comprising the steps of:

[0041] (1) Weigh raw material pure Mg (99.99%), pure Zn (99.99%), pure Mn (99.99%), pure Sr (99.99%) according to the ratio of Mg:Zn:Mn:Sr=97.5:1:1:0.5 , where Sr (99.99%) added 0.5%;

[0042] (2) Put pure magnesium and other materials together in a graphite crucible, heat the resistance furnace to 760°C to melt all raw materials, and keep stirring, stop heating and let stand;

[0043] (2) After smelting, pour the melt into a steel mold preheated to 200°C, and finally cool completely to obtain a Mg-Zn-Mn-Sr quaternary alloy;

[0044] The entire smelting process is carried out in CO 2 (99.5%) and SF 6 (0.5%) in a mixed protective gas.

Embodiment 3

[0046] The specific preparation method is the same as that of Example 2, but, wherein Mg:Zn:Mn:Sr=97:1:1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com