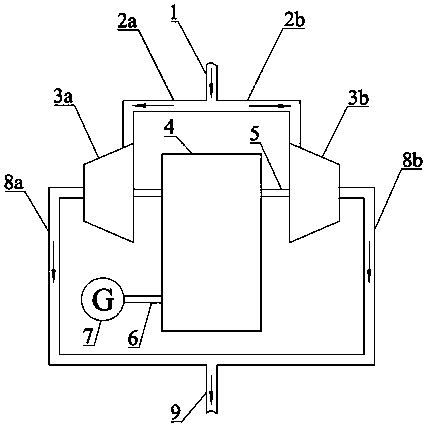

Parallel double-head separate exhaust type radial turbine

A turbine and parallel technology, applied in blade support elements, engine elements, machines/engines, etc., can solve large axial forces, unstable rotor dynamics, and it is difficult for centripetal turbines to achieve higher power and higher efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

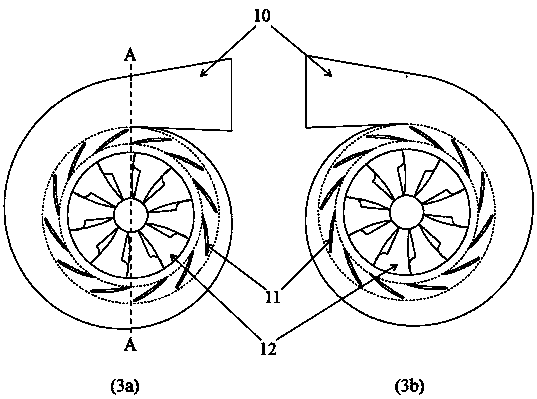

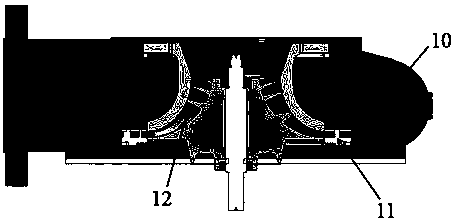

Method used

Image

Examples

Embodiment example

[0025] An industrial park needs to provide the enterprises in the park with saturated steam for production. The hourly demand is 35 tons and the steam pressure is 0.6 MPa. The main steam pressure provided by the boiler in the park is 2.35 MPa and the temperature is 400 °C. The main steam is desuperheated and decompressed by the back-pressure centrifugal turbine, and the turbine drives the generator to output electric energy. The exhaust pressure of the turbine is 0.6 MPa, and is further reduced in temperature by spraying water, and then sent to the steam user after reaching saturation. If the single-impeller type centrifugal turbine is used, the size of the impeller is large and the rotational speed is also high, which is difficult to meet the requirements of balancing the axial force and ensuring the stability of the rotor dynamics. The parallel double-head separately exhausted centripetal turbine of the present invention is used here. The inlet and exhaust parameters of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com