Full-automatic scanning location and quantitative analysis system for global components of large-scale samples

A quantitative analysis and large-scale technology, which is applied in the direction of material analysis, thermal excitation analysis, material excitation analysis, etc., can solve the problems of limited test sample size, complex operation, large volume, etc., and achieves the convenience of control and overall machine design and application Large-scale, small-volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the present invention and together with the embodiments of the present invention are used to explain the principles of the present invention and are not intended to limit the scope of the present invention.

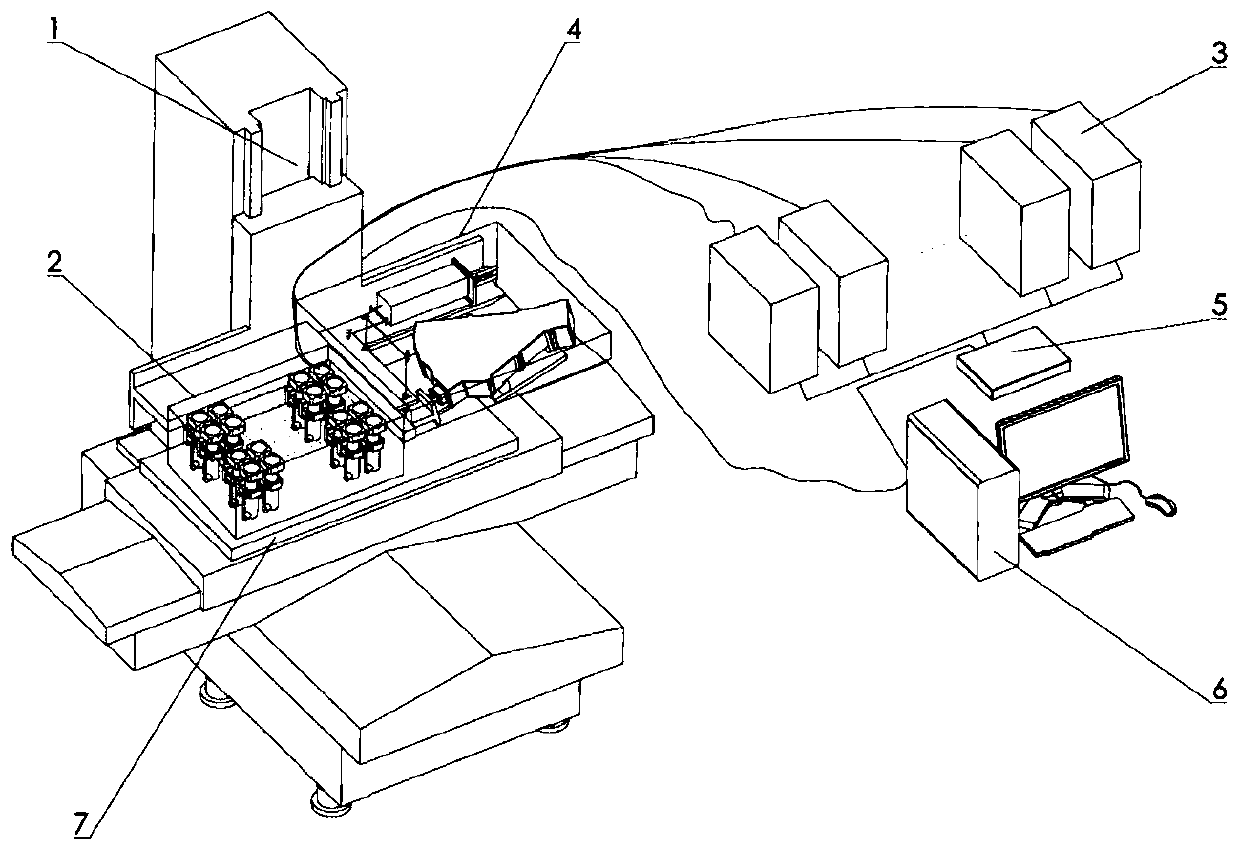

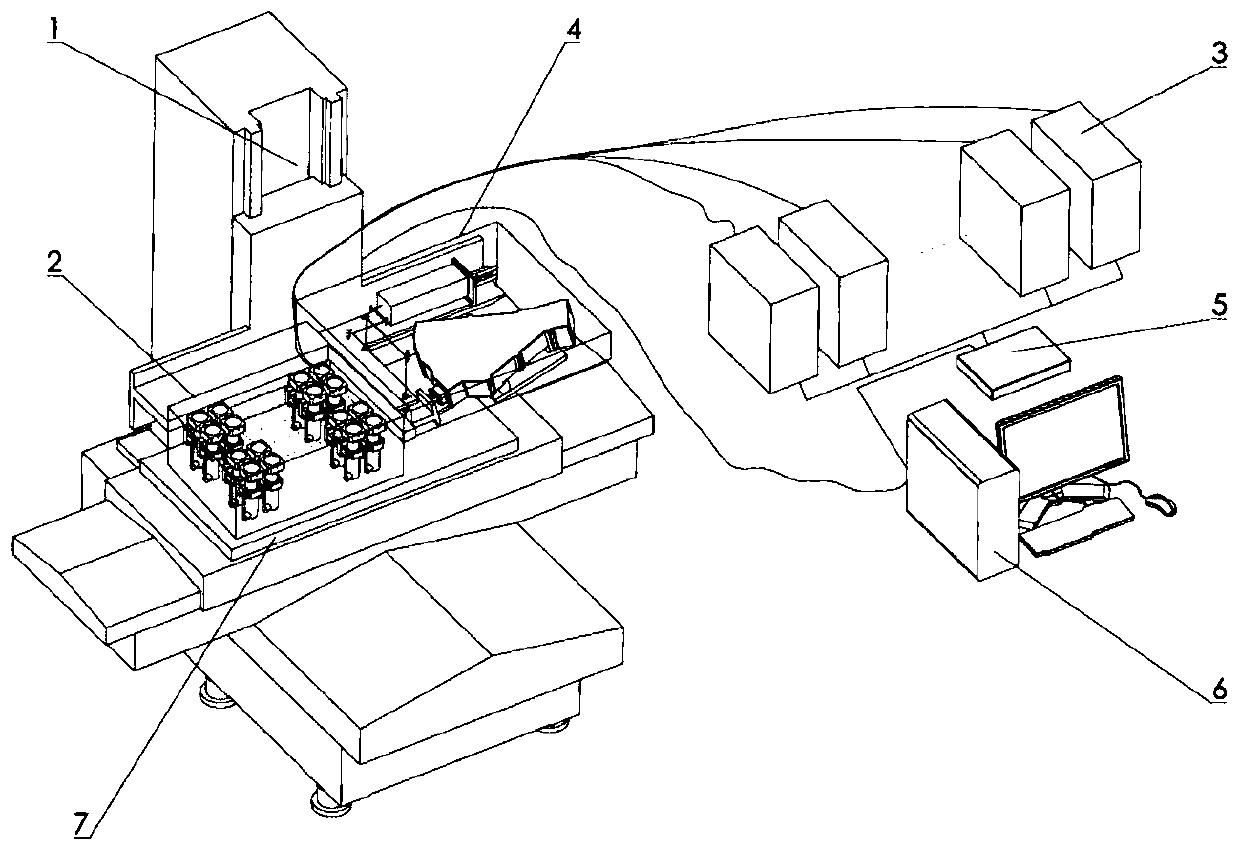

[0037] A specific embodiment of the present invention discloses a fully automatic scanning, positioning and quantitative analysis system for global components and inclusions in large-scale samples, such as figure 1 As shown, it includes a high-precision numerical control workbench system 1 , a photomicrograph matrix system 2 , a GPU workstation group 3 , a laser spectrometer 4 , a network switch 5 and a terminal server 6 .

[0038] During implementation, the microphotography matrix system 2 and the GPU workstation group 3 are used to control the high-precision numerical control w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com