Segment assembly measuring and control system and method based on machine vision

A technology of segment assembly and machine vision, applied in the direction of measuring devices, instruments, shaft equipment, etc., can solve the problems of low efficiency and precision, improve precision and efficiency, avoid low measurement accuracy and efficiency, and overcome high manpower requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

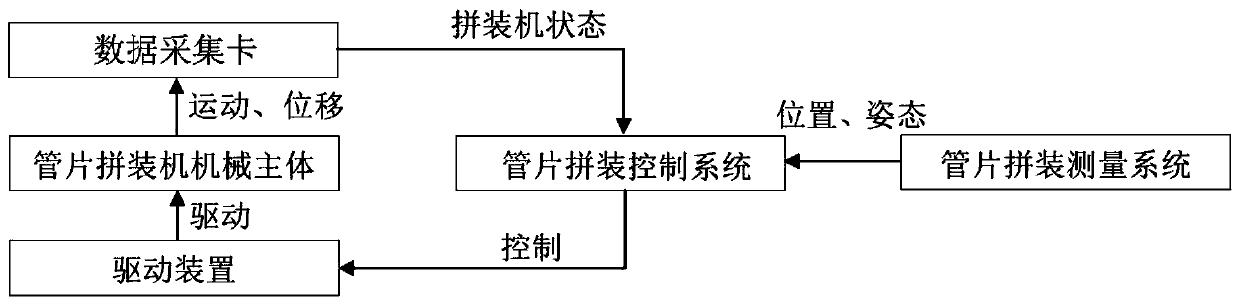

[0042] Such as figure 1 As shown, the present invention provides a segment assembly measurement and control system based on machine vision, including:

[0043] The industrial camera is used to collect images of the segment to be assembled and the end effector of the segment assembly machine and transmit the image to the segment assembly measurement system;

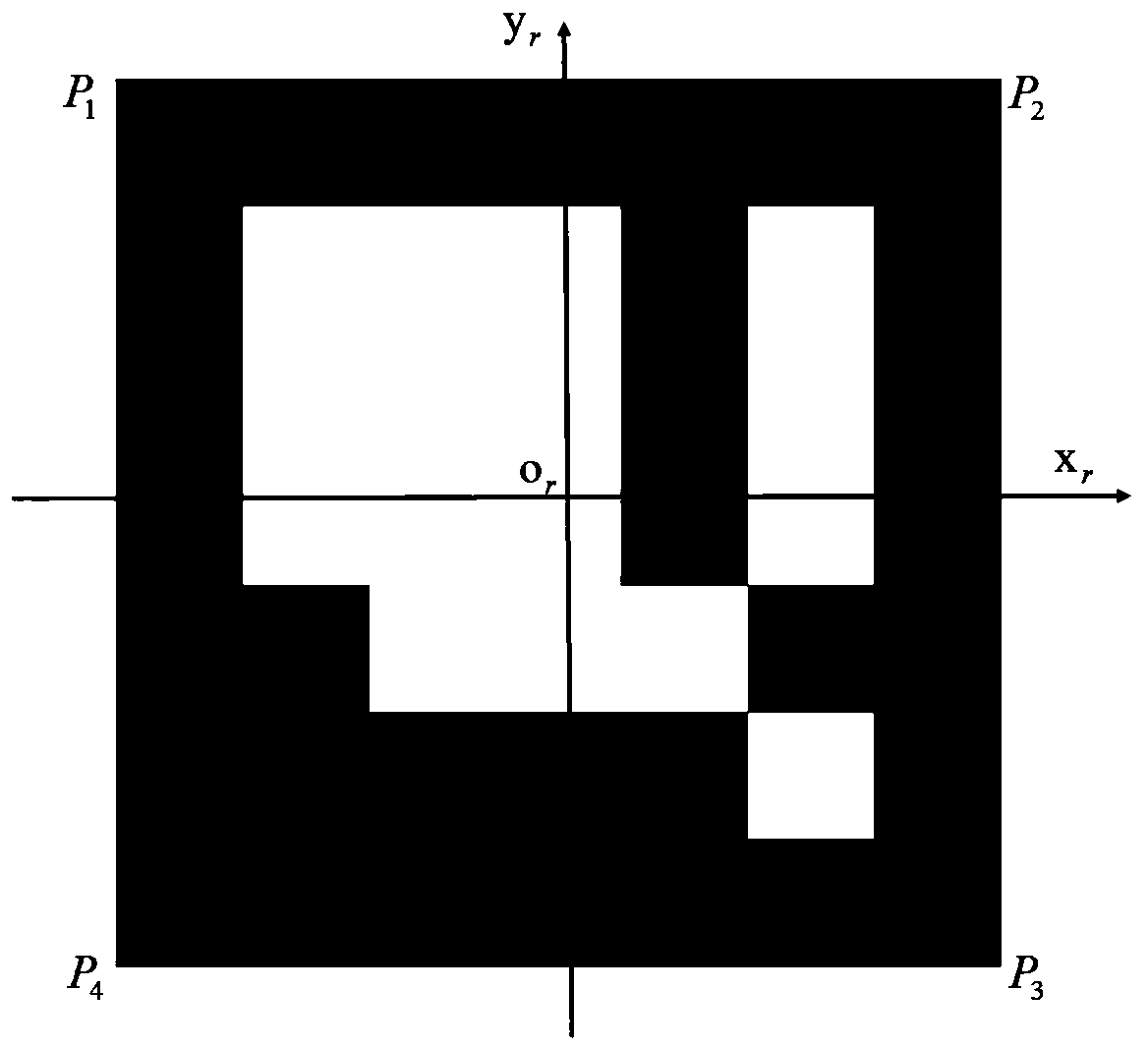

[0044] The segment assembly measurement system is used to identify the coordinates of the marked feature points corresponding to the end effector in the image and the segment to be assembled, and use the P4P pose measurement algorithm to measure the position and position of the end effector and the segment to be assembled in real time according to the recognition result Attitude, which realizes the non-contact measurement of the position and orientation of the end effector and the segment to be assembled based on vision measurement, to replace the traditional human measurement; the segment assembly measurement system is al...

Embodiment 2

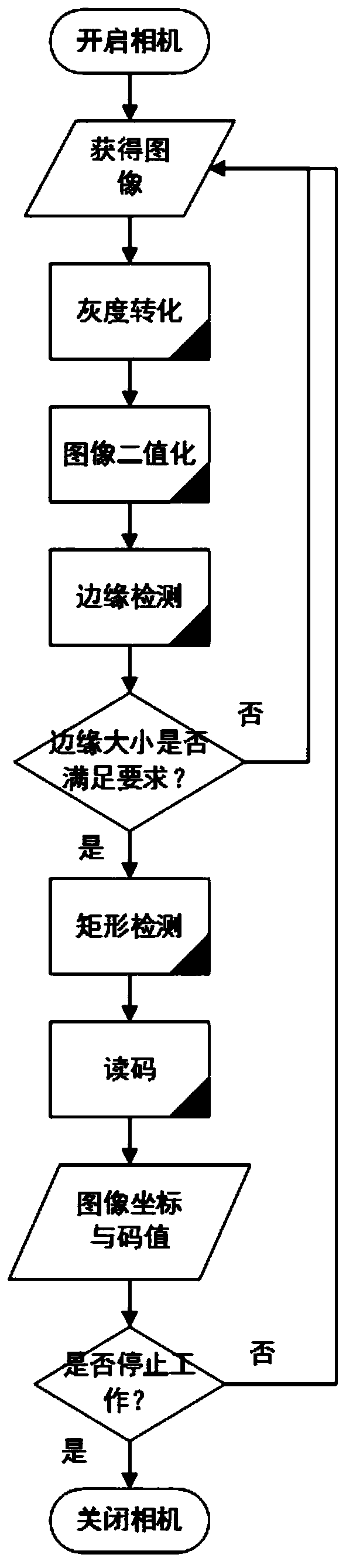

[0116] Such as Figure 5 As shown, the present invention also provides a machine vision-based segment assembly measurement and control method, using the machine vision-based segment assembly measurement and control system described in Embodiment 1, comprising the following steps:

[0117] S1: Collect the images of the end effector of the segment assembly machine and the segments to be assembled through the camera, and transmit the images to the segment assembly measurement system of the industrial computer;

[0118] S2: The segment assembly measurement system recognizes the coordinates of the marked feature points corresponding to the end effector in the image and the segment to be assembled, and calculates the positions and attitudes of the end effector and the segment to be assembled respectively according to the recognition results;

[0119] S3: Calculate the deviation value between the position and attitude of the end effector and the position and attitude of the segment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com