Corn harvester based on visual detection technology

A corn harvester and visual inspection technology, applied in the direction of harvesters, agricultural machinery and implements, threshing equipment, etc., can solve the problems of high power consumption of harvesting devices, low harvesting efficiency, poor purity, etc., and achieve accurate harvesting and threshing processing , high degree of automation, save the effect of human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0035]The control unit, the CCD image acquisition assembly and the horizontal position sensing assembly involved in the present invention all adopt conventional functions in its prior art, so that the present invention has a visual detection function. This function itself is a prior art, and the present invention does not aim at The improvement of these visual detection components and their connection relationship is aimed at the improvement of the entire mechanical system, and on this basis, the visual detection function in the prior art is added.

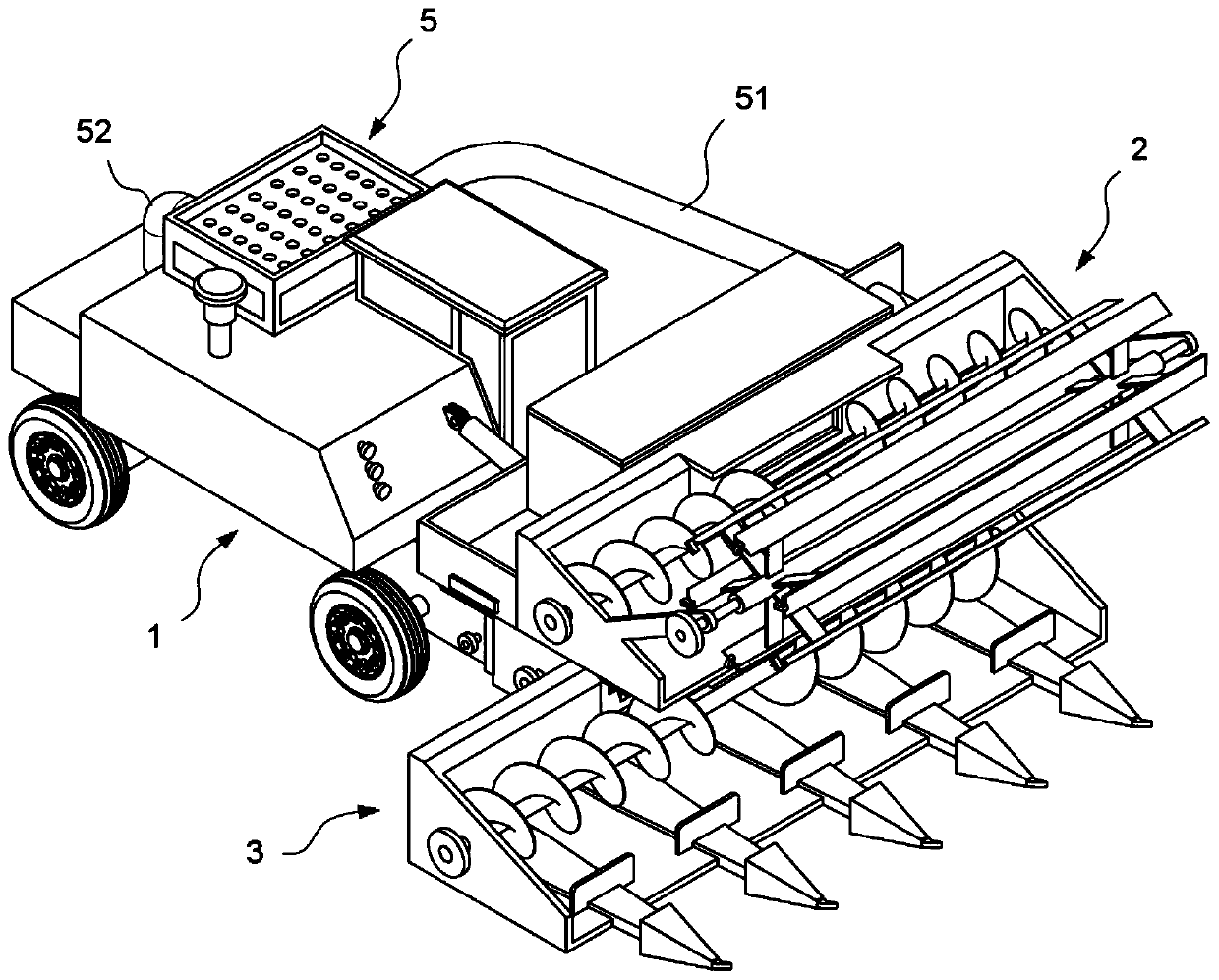

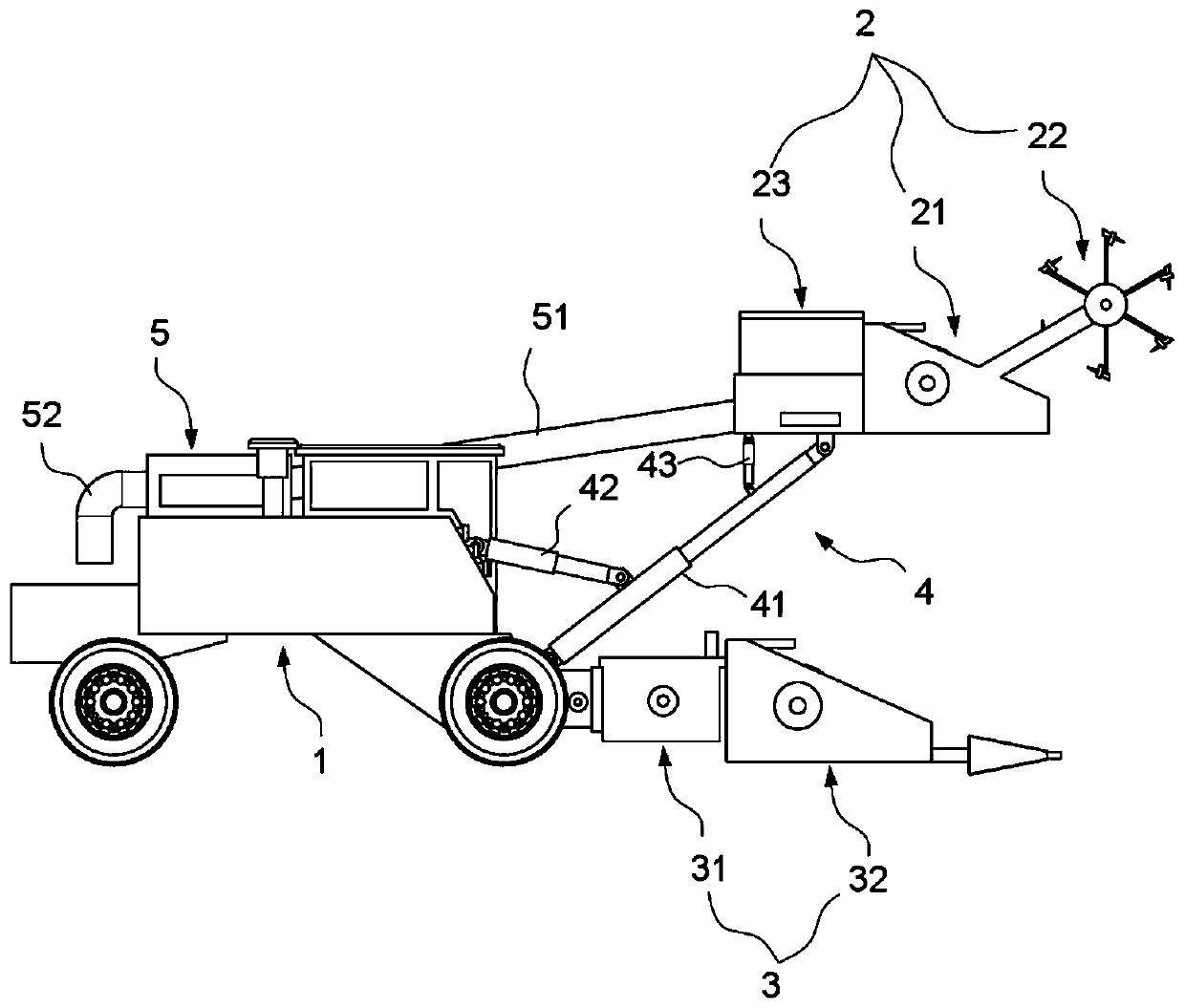

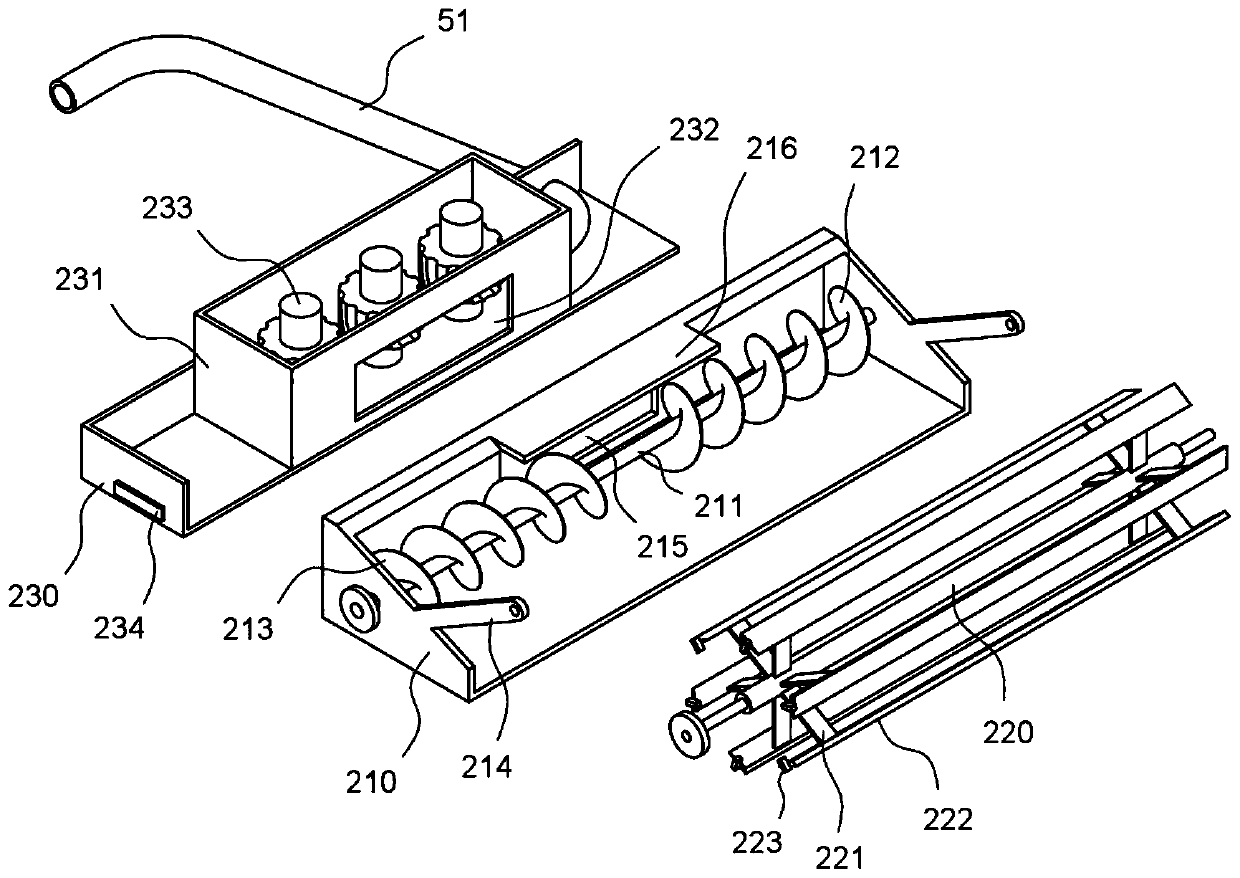

[0036] Such as figure 1 — Figure 5 As shown, the invention provides a kind of corn harvester based on visual inspection technology, comprising:

[0037] Trailer mechanism 1, which is used for driving operations in the corn har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com