Method for preparing SCR denitration catalyst by using rare earth tailings

A technology for denitrification catalysts and rare earth tailings, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of tailings miscellaneous and underutilized, etc., to increase the specific surface area and save resources , Improve the effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

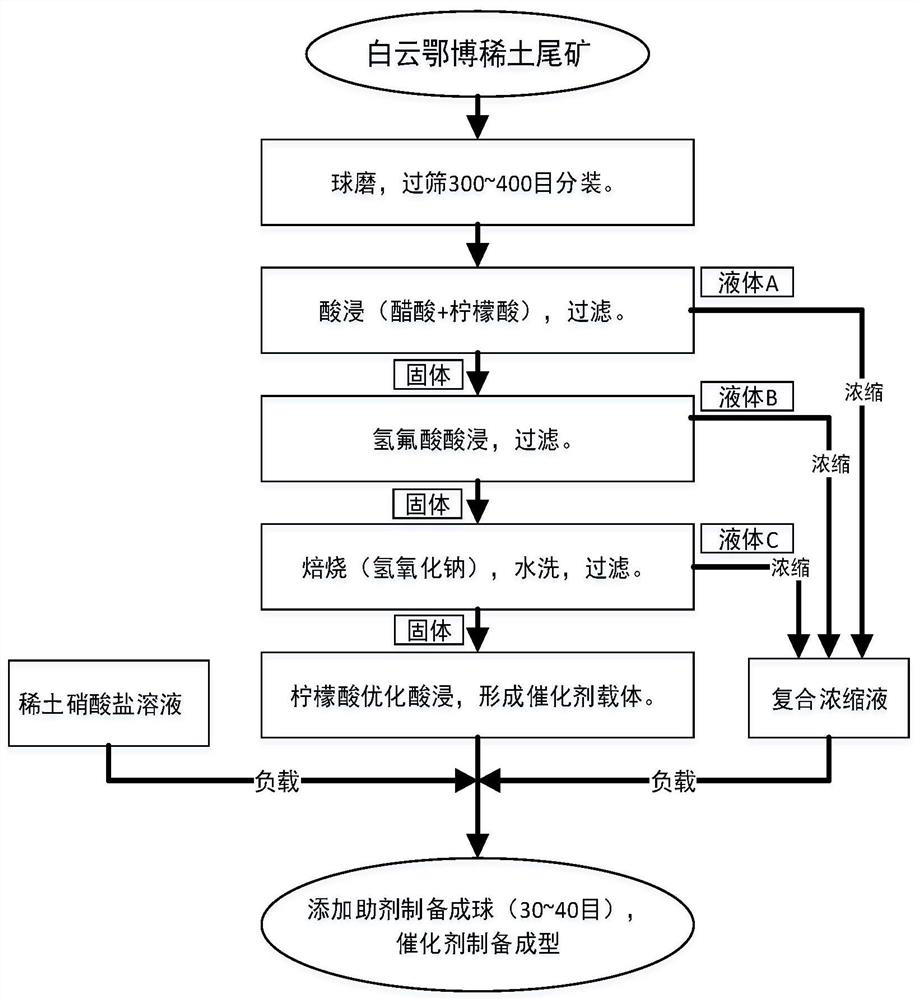

Method used

Image

Examples

Embodiment 1

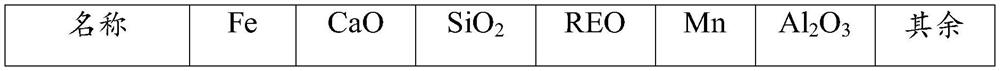

[0035] Put the rare earth tailings into a ball mill for ball milling, screen 300-400 mesh particle size and pack; weigh 500g of rare earth tailings and acetic acid and citric acid (the molar concentration of acetic acid is 8mol / L, and the molar concentration of citric acid is 4mol / L ) mixed acid, the liquid-solid ratio is 1:2, the immersion time is 2h, and then washed with water to obtain the acetic acid leaching tailings and solution A, and the acetic acid leaching tailings are dried.

[0036] Acetic acid leaching tailings and HF acid (the molar concentration of HF acid is 4mol / L) are mixed, the liquid-solid ratio is 1:1, the immersion time is 1.5h, and then washed and filtered to obtain HF acid leaching tailings and solution B, Dry HF acid leaching tailings.

[0037] Mix the dried HF acid leaching tailings with NaOH solution (the mass concentration of NaOH solution is 8%), let it stand for 1.5h, wash and filter with water, and obtain acid-base treatment tailings and solution...

Embodiment 2

[0043] Put the rare earth tailings into a ball mill for ball milling, screen 300-400 mesh particle size and pack; weigh 500g of rare earth tailings and acetic acid and citric acid (the molar concentration of acetic acid is 10mol / L, and the molar concentration of citric acid is 3mol / L ) mixed with an equal volume of mixed acid, the liquid-solid ratio is 1:1, the immersion time is 2h, and then washed with water to obtain the acetic acid leaching tailings and solution A, and the acetic acid leaching tailings are dried.

[0044] Mix acetic acid leaching tailings and HF acid (the molar concentration of HF acid is 2mol / L), the liquid-solid ratio is 1:2, the immersion time is 2h, and then wash and filter with water to obtain HF acid leaching tailings and solution B, and dry Dry HF acid leaching tailings.

[0045] Mix the dried HF acid leaching tailings with NaOH solution (the mass concentration of NaOH solution is 11%), the liquid-solid ratio is 1:2, the standing time is 15min, wash ...

Embodiment 3

[0051] Put the rare earth tailings into a ball mill for ball milling, screen 300-400 mesh particle size and pack; weigh 500g of rare earth tailings, acetic acid and citric acid (the molar concentration of acetic acid is 5mol / L, and the molar concentration of citric acid is 1.5mol / L L) is mixed with the mixed acid, the liquid-solid ratio is 1:3, the immersion time is 2h, and then washed with water to obtain the acetic acid leaching tailings and solution A, and the acetic acid leaching tailings are dried.

[0052] Mix acetic acid leaching tailings and HF acid (the molar concentration of HF acid is 2mol / L), the liquid-solid ratio is 1:3, the immersion time is 3h, and then wash and filter with water to obtain HF acid leaching tailings and solution B, and dry Dry HF acid leaching tailings.

[0053] Mix the dried HF acid leaching tailings with NaOH solution (the mass concentration of NaOH solution is 15%), let it stand for 1.5h, wash and filter with water, and obtain acid-base treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com