High-strength composite plywood

A plywood, high-strength technology, applied in the field of plywood, can solve the problem of unavailability of the remaining materials of rotary cutting, and achieve the effects of enhanced strength, good antibacterial effect and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

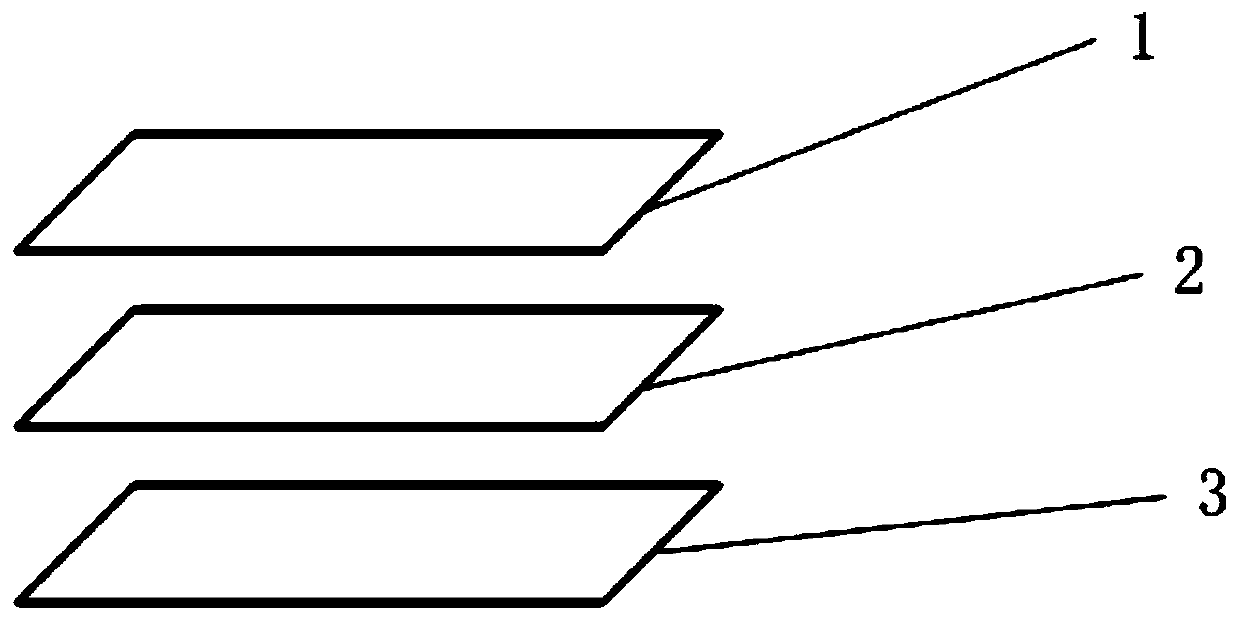

[0035] Such as Figure 1-3 Shown, a kind of high-strength composite plywood, it comprises middle fiber board 2, upper layer veneer and lower layer veneer, the upper side of described middle fiber board 2 is fixedly connected with upper single layer board 1, and the lower side of described middle fiber board 2 is fixed connected to the lower veneer;

[0036] Wherein, the preparation method of the high-strength composite plywood is: the upper side and the lower side of the middle fiberboard 2 are evenly sprayed with an adhesive, and the upper single-layer board 1 and the lower single-layer board 3 are respectively bonded to the middle The upper and lower sides of the fiberboard 2 are shaped by hot pressing to obtain the high-strength composite plywood;

[0037] The preparation method of the intermediate fiberboard 2 comprises the following steps:

[0038] S1. Mix magnesium chloride, indium oxide, and yttrium oxide with a particle size of 100 mesh evenly, and add them to the al...

Embodiment 2

[0042] Such as Figure 1-3 Shown, a kind of high-strength composite plywood, it comprises middle fiber board 2, upper layer veneer and lower layer veneer, the upper side of described middle fiber board 2 is fixedly connected with upper single layer board 1, and the lower side of described middle fiber board 2 is fixed connected to the lower veneer;

[0043] Wherein, the preparation method of the high-strength composite plywood is: the upper side and the lower side of the middle fiberboard 2 are evenly sprayed with an adhesive, and the upper single-layer board 1 and the lower single-layer board 3 are respectively bonded to the middle The upper and lower sides of the fiberboard 2 are shaped by hot pressing to obtain the high-strength composite plywood;

[0044] The preparation method of the intermediate fiber board 2 comprises the following steps:

[0045] S1. Mix magnesium chloride with a particle size of 80 mesh, indium oxide and yttrium oxide evenly, and add them to the alk...

Embodiment 3

[0049] Such as Figure 1-3 Shown, a kind of high-strength composite plywood, it comprises middle fiber board 2, upper layer veneer and lower layer veneer, the upper side of described middle fiber board 2 is fixedly connected with upper single layer board 1, and the lower side of described middle fiber board 2 is fixed connected to the lower veneer;

[0050] Wherein, the preparation method of the high-strength composite plywood is: the upper side and the lower side of the middle fiberboard 2 are evenly sprayed with an adhesive, and the upper single-layer board 1 and the lower single-layer board 3 are respectively bonded to the middle The upper and lower sides of the fiberboard 2 are heat-pressed to obtain the high-strength composite plywood; wherein, the upper single-layer board 1 and the lower single-layer board 3 are coated with polyvinyl alcohol film, and the upper single-layer board 1 and the lower single-layer board 3 are coated with polyvinyl alcohol film, and the upper s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com