Preparation method of stone-texture-imitated die, and method for manufacturing quartz stone plate through using stone-texture-imitated die

A technology for manufacturing quartz stone slabs and molds, which is applied in the field of artificial quartz stone processing, can solve the problems of unnatural cutting texture, complicated production process, low preparation efficiency, etc., and achieves the effect of saving time, compact preparation process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a kind of preparation method of imitation stone texture mould, comprising the following steps:

[0036] (a) Scan the texture of the stone, print it on paper, draw and adjust the texture outline with a pen according to the texture on the paper, obtain the draft of the texture pattern of the quartz stone slab to be produced, and make a CAD drawing;

[0037] (b) Import the CAD drawing into the CNC software of the water jet cutting machine, set the water jet program, set the cutting route, and select the cutting point;

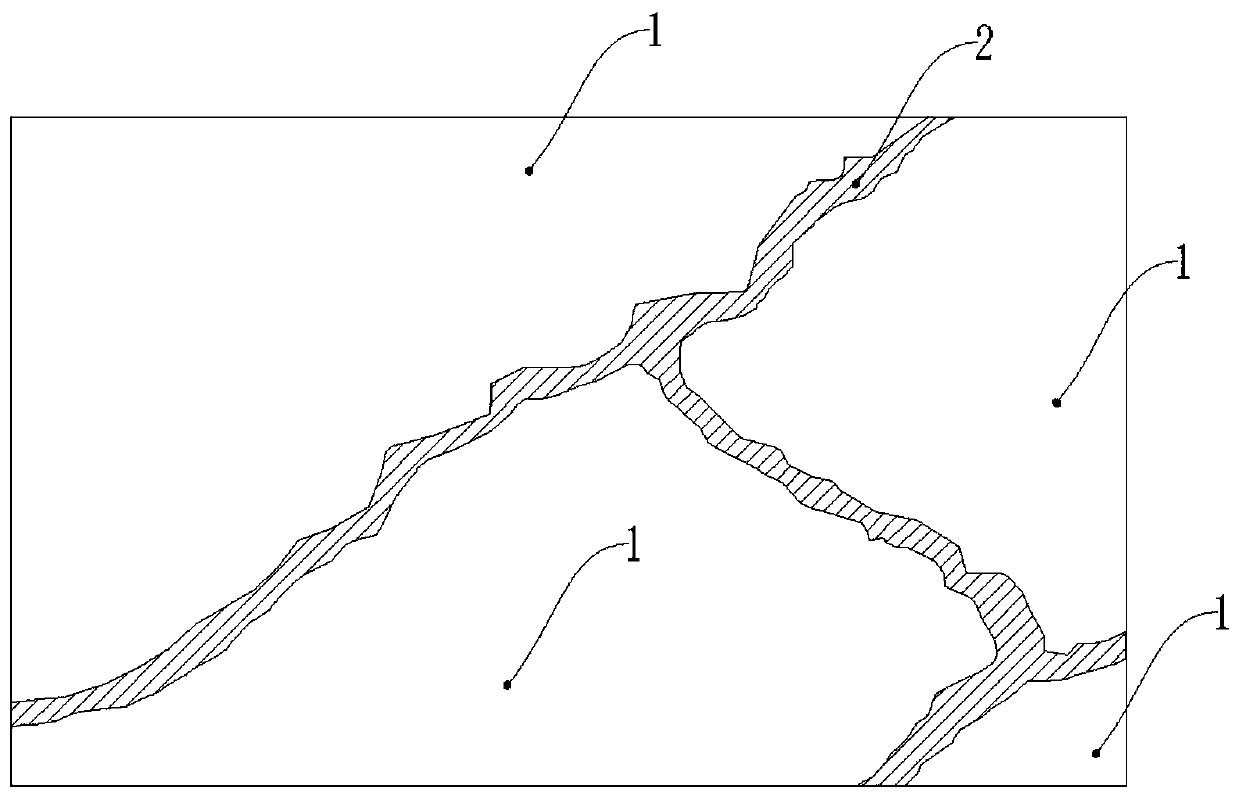

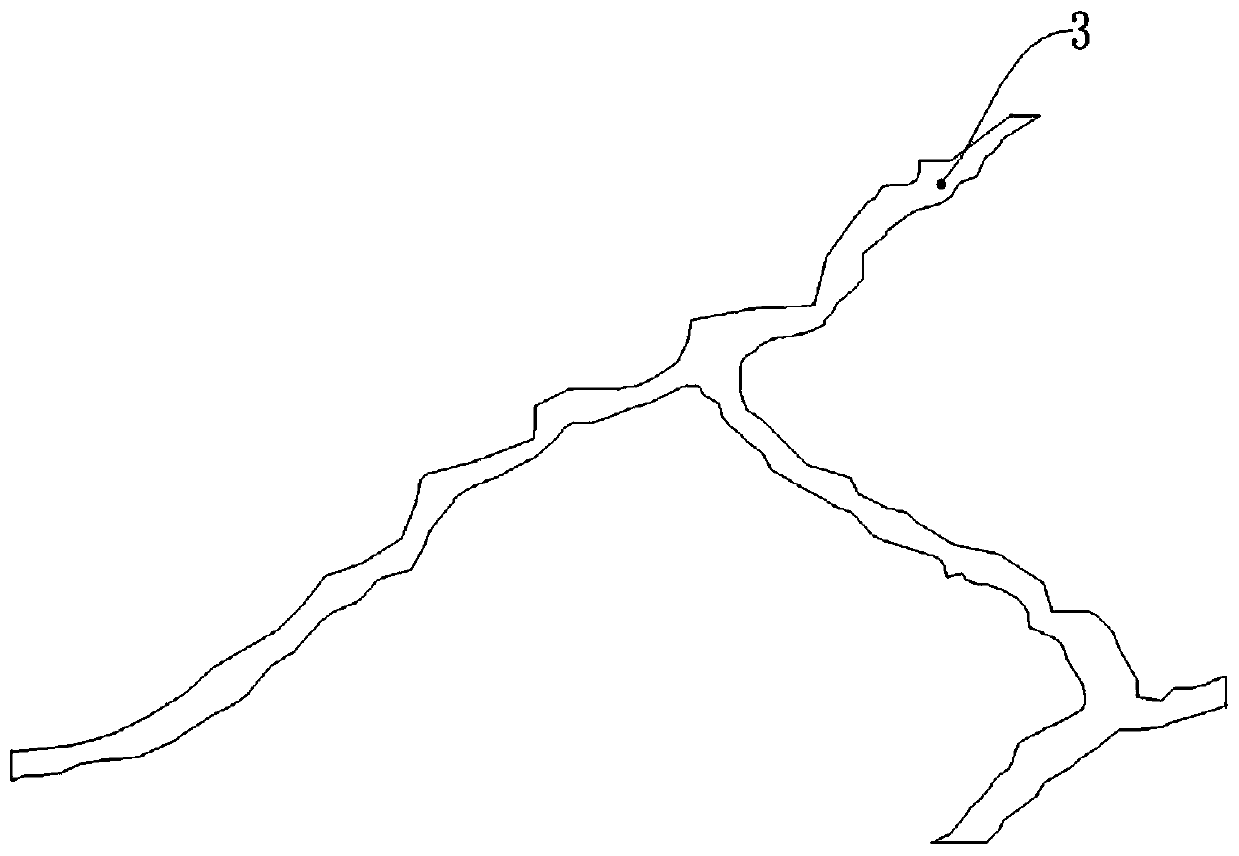

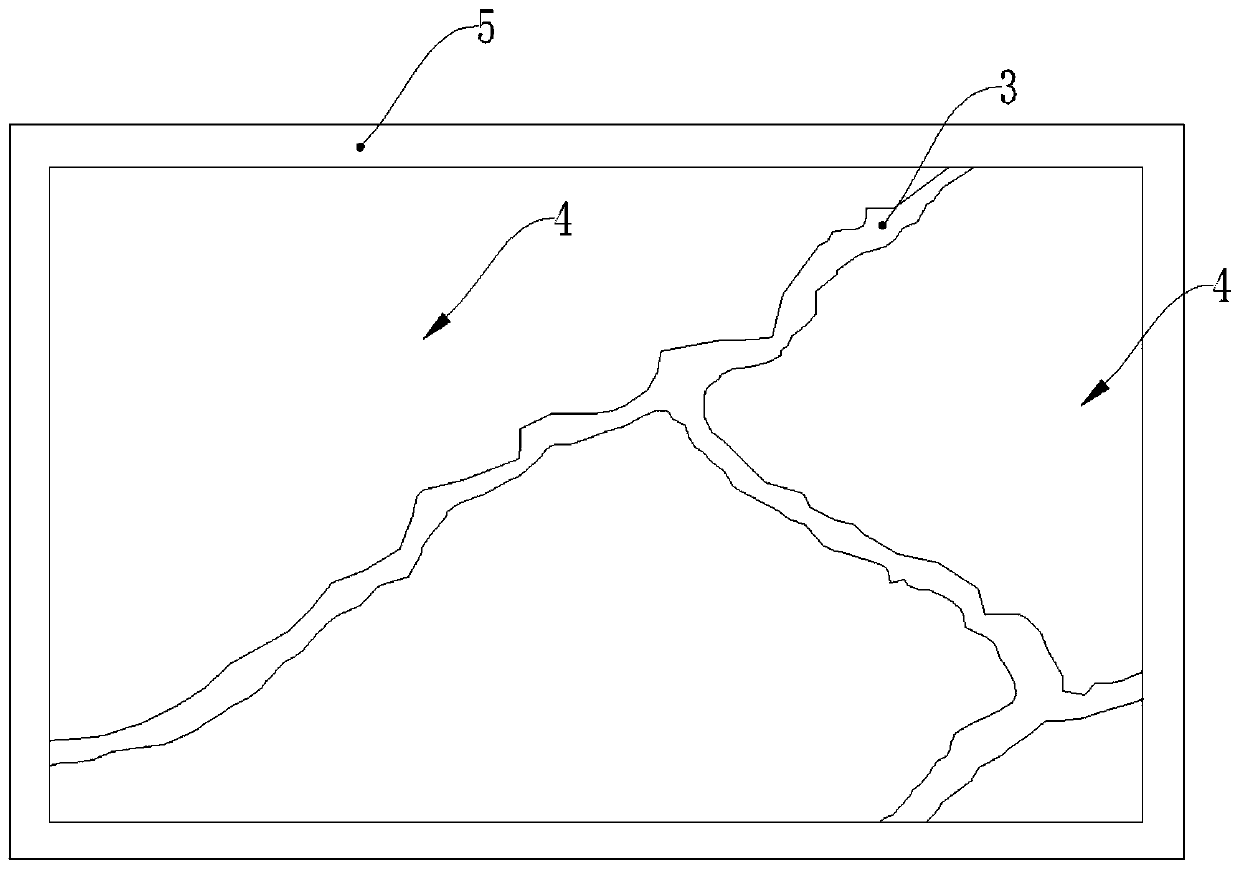

[0038] (c) Fix the board to be cut on the water jet cutting table, turn on the water jet cutting machine, and the cutter head will cut according to the cutting route. After the cutting board is cut, a non-stone texture area 1 and a stone texture area 2 will be formed. The stone texture area 1 forms a hollow 4, and the remaining stone texture area 2 is a cut piece, which is consistent with the texture of the CAD drawing, such a...

Embodiment

[0073] 1. Preparation of imitation stone texture mold:

[0074] (a) Scan the texture of the stone, print it on paper, draw and adjust the texture outline with a pen according to the texture on the paper, obtain the draft of the texture pattern of the quartz stone slab to be produced, and make a CAD drawing;

[0075] (b) Import the CAD drawing into the numerical control software of the water jet cutting machine to generate the water jet program: the jetting pressure is 200MPa, the cutting speed is 100mm / min, the cutting route is set, and the cutting point is selected;

[0076] (c) Fix the PE board to be cut on the water jet cutting table, select a 0.4mm cutter head, and mix sand into the water ejected from the cutter head. The particle size of the sand is 400 mesh, and the flow rate of the sand is controlled at 0.3kg when adding the sand. / min. Turn on the waterjet cutting machine, and the cutter head performs three-dimensional cutting according to the cutting route. After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com