Argon microwave discharge plasma assisted methane and air swirling combustion device and method

A technology of microwave discharge and plasma, which is applied in the direction of combustion method, plasma, gas fuel burner, etc., can solve the complicated problems of swirl burner, achieve the effect of improving magnitude and dispersion, efficient combustion, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides an argon microwave discharge plasma-assisted methane-air swirl combustion device. Through the synergistic effect of microwave discharge and swirl combustion, under atmospheric pressure conditions, the high-efficiency combustion of argon microwave discharge plasma-assisted methane-air mixture gas is realized. combustion.

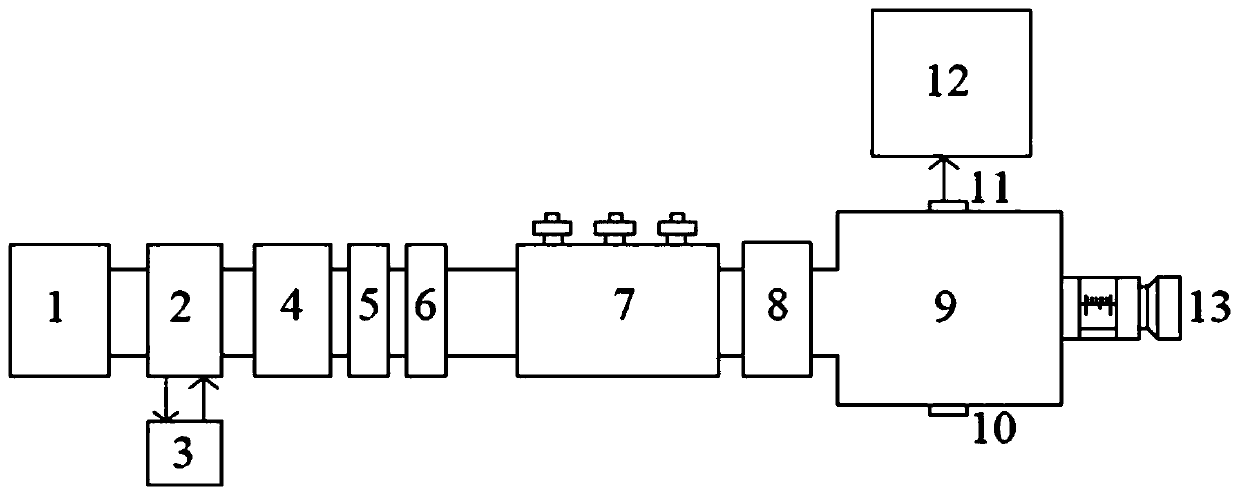

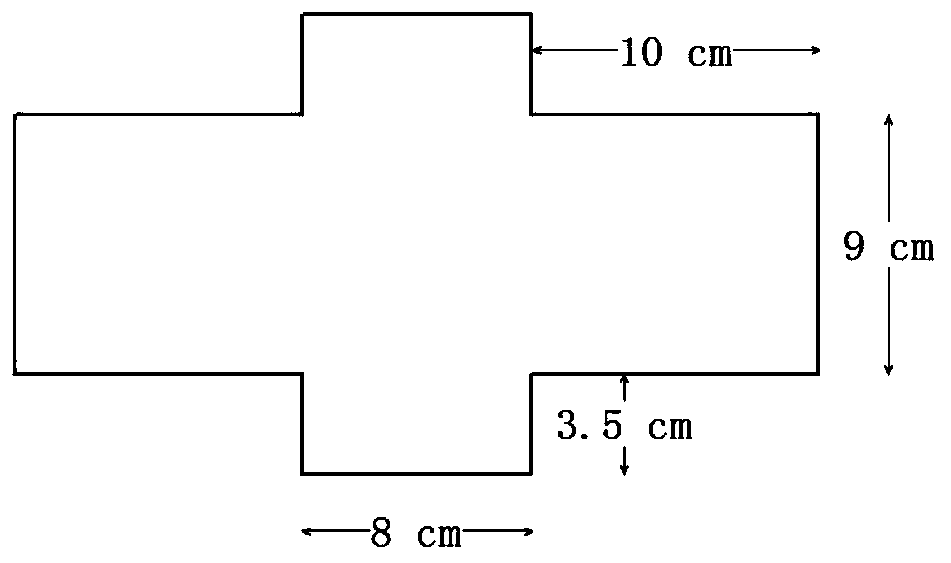

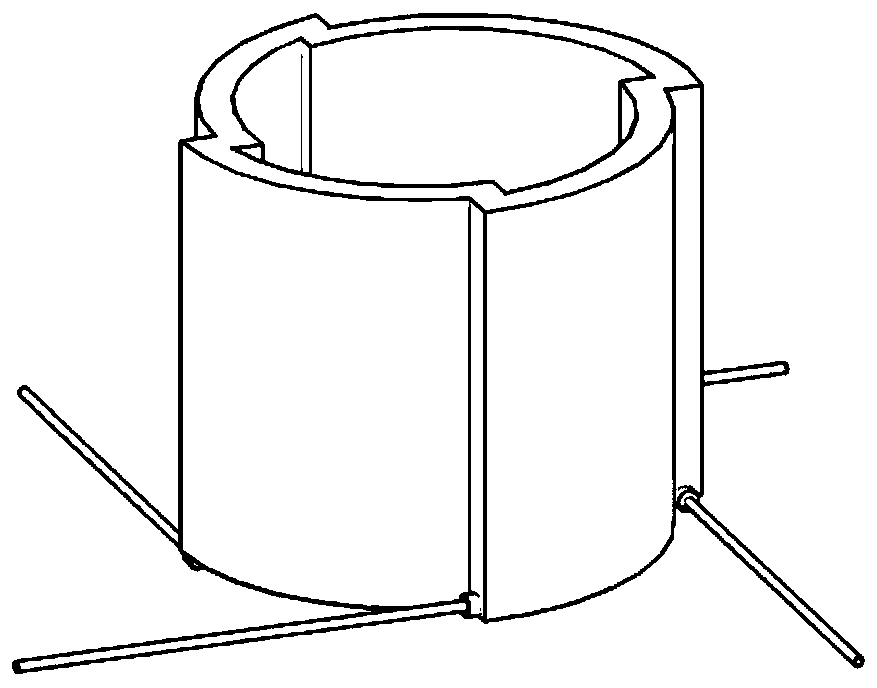

[0043] Please refer to the attached figure 1 , the argon microwave discharge plasma assisted methane air swirling combustion device includes a microwave power source 1, a microwave anti-reflux device, a three-pin adjuster 7, a conversion waveguide 8 and a microwave resonant cavity 9 connected in sequence, and the microwave power The source 1 drives the microwave discharge, and the microwave energy sequentially passes through the microwave anti-reflux device to isolate the reflected wave, the impedance matching of the three-pin adjuster 7 and the mode conversion of the conversion waveguide 8, and then enters the microwave resona...

Embodiment 2

[0060] This embodiment provides a working method of an argon microwave discharge plasma assisted methane air swirling combustion device, the method comprising the following steps:

[0061] S101, the microwave power source drives the microwave discharge to generate microwave energy;

[0062] S102, the microwave energy enters the microwave resonant cavity after sequentially passing through the microwave anti-reflux device to isolate the reflected wave, the impedance matching of the three-pin adjuster, and the converted waveguide mode conversion;

[0063] S103, the atmospheric pressure argon microwave discharge plasma is formed in the microwave resonant cavity and transported to the swirl burner;

[0064] S104, methane and air enter the swirl burner tangentially from the gas inlet alternately through the pressure reducing valve and the gas flow meter respectively;

[0065] S105, realizing stable combustion of methane and air in a swirl burner with the assistance of microwave arg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com