A bionic fully formed three-phase artificial ligament and its preparation method

An artificial ligament, fully formed technology, applied in ligament, medical science, prosthesis, etc., can solve the problems of mismatched growth rate of new tissue during ligament degradation time, insufficient mechanical properties, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

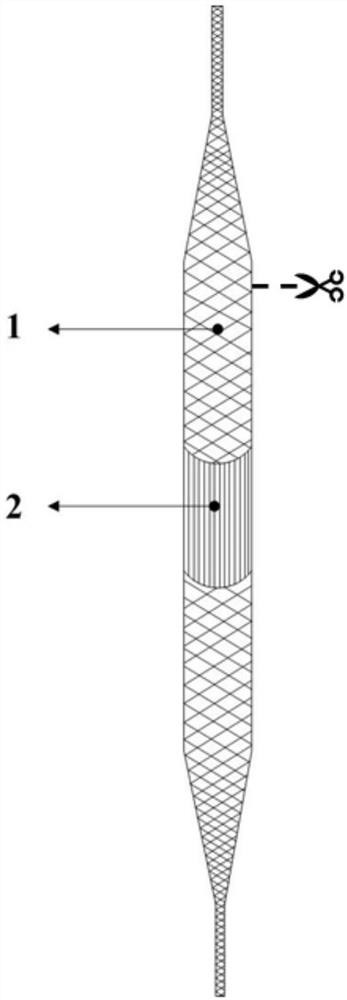

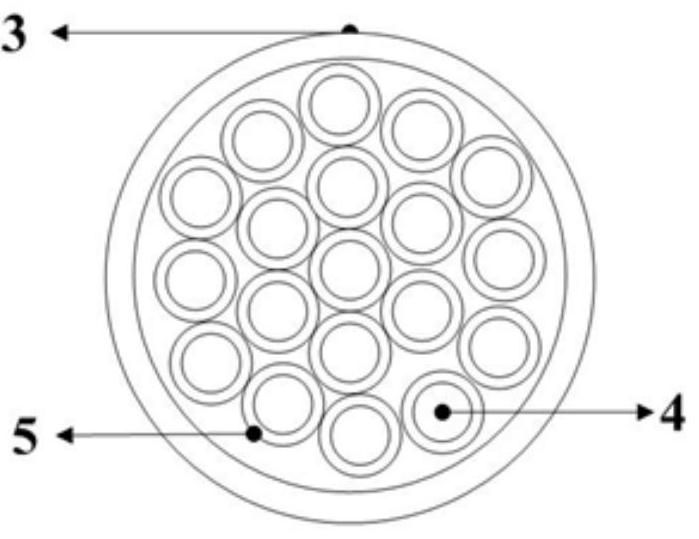

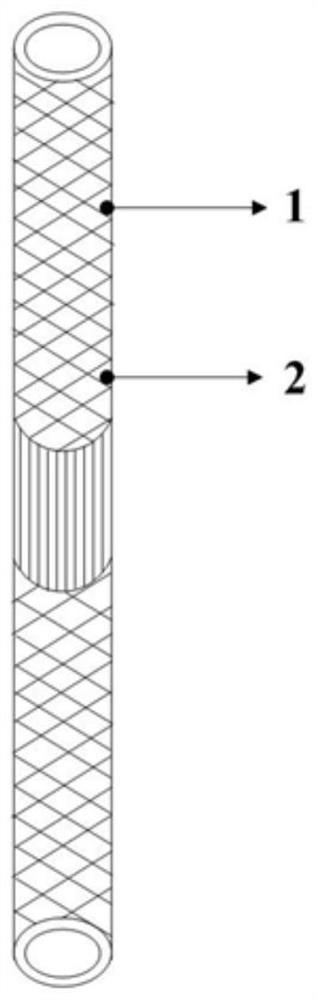

[0034] The preparation method of the bionic fully formed three-phase structure artificial ligament shown in Figure 1 is:

[0035] The first step is to determine the yarn and ligament structure parameters. Yarn A, yarn B, and yarn C are PPDO, PGCL, and PGLA respectively. The diameter of a single yarn is 0.3mm, and the complete degradation time is 11 months, 9 months, and 4 months, respectively. The proportions are 40%, 40% and 20% in turn. The diameter of the bionic fully formed three-phase structure artificial ligament is 5.7mm, the diameter of the three-phase small-diameter braided bundle of the nuclear layer is 1.8mm, the length of the bone tunnel braided section is 3mm, and the joint cavity fiber The beam segment is 2.5mm long.

[0036] The second step is the weaving of three-phase small diameter braided bundles. Install the spindles on a 24-spindle braiding machine according to a specific loading method, without adding an inner tube, and weave directly so that the two en...

Embodiment 2

[0041] The preparation method of the bionic fully formed three-phase structure artificial ligament shown in Figure 1 is:

[0042]The first step is to determine the yarn and ligament structure parameters. Yarn A, yarn B, and yarn C are P4HB, PPDO, and PGCL respectively. The diameter of a single yarn is 0.3mm, and the complete degradation time is 15 months, 11 months, and 6 months. The proportions are 50%, 37.5% and 12.5% in turn. The diameter of the bionic fully formed three-phase structure artificial ligament is 6.2 mm, the diameter of the three-phase small-diameter braided bundle of the nuclear layer is 2 mm, the length of the bone tunnel braided section is 3 mm, and the joint cavity fiber bundle The segment length is 2.5 mm.

[0043] The second step is the weaving of three-phase small diameter braided bundles. Install the spindles on a 24-spindle braiding machine according to a specific loading method, without adding an inner tube, and weave directly so that the two ends...

Embodiment 3

[0048] The preparation method of the bionic fully formed three-phase structure artificial ligament shown in Fig. 1 is:

[0049] The first step is to determine the yarn and ligament structure parameters. Yarn A, yarn B, and yarn C are P4HB, PPDO, and PGCL respectively. The diameter of a single yarn is 0.3mm, and the complete degradation time is 15 months, 11 months, and 6 months. The proportions are 60%, 30% and 10% in turn. The diameter of the bionic fully formed three-phase structure artificial ligament is 7.1 mm, the diameter of the three-phase small-diameter braided bundle of the nuclear layer is 2.3 mm, the length of the bone tunnel braided segment is 3 mm, and the joint cavity fiber The beam segment is 2.5mm long.

[0050] The second step is the weaving of three-phase small diameter braided bundles. Install the spindles on a 24-spindle braiding machine according to a specific loading method, without adding an inner tube, and weave directly so that the two ends are bone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com