Hyaluronic acid microneedle patch and preparation method thereof

A technology of hyaluronic acid and micro-needle stickers, applied in the field of skin care products, can solve the problems of only staying on the surface of the skin, complicated formulas, and insignificant effects, and achieves the effect of natural color, reasonable compatibility and rich moisturizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a hyaluronic acid microneedle patch, which includes the following raw materials in parts by weight: 5 parts of hyaluronic acid, 1 part of collagen, 15 parts of butanediol, 8 parts of arbutin, 2 parts of sodium ascorbyl phosphate, formazan Base isothiazolinone 0.01 part, deionized water 67 parts.

[0034] The preparation method comprises the following steps:

[0035] S1: Preparation of raw slurry: Weigh each raw material according to the ratio of parts by weight, put it into a vacuum emulsification pot, heat it to 50°C under stirring conditions, continue to stir until it dissolves evenly, and vacuumize and defoam to obtain the raw slurry;

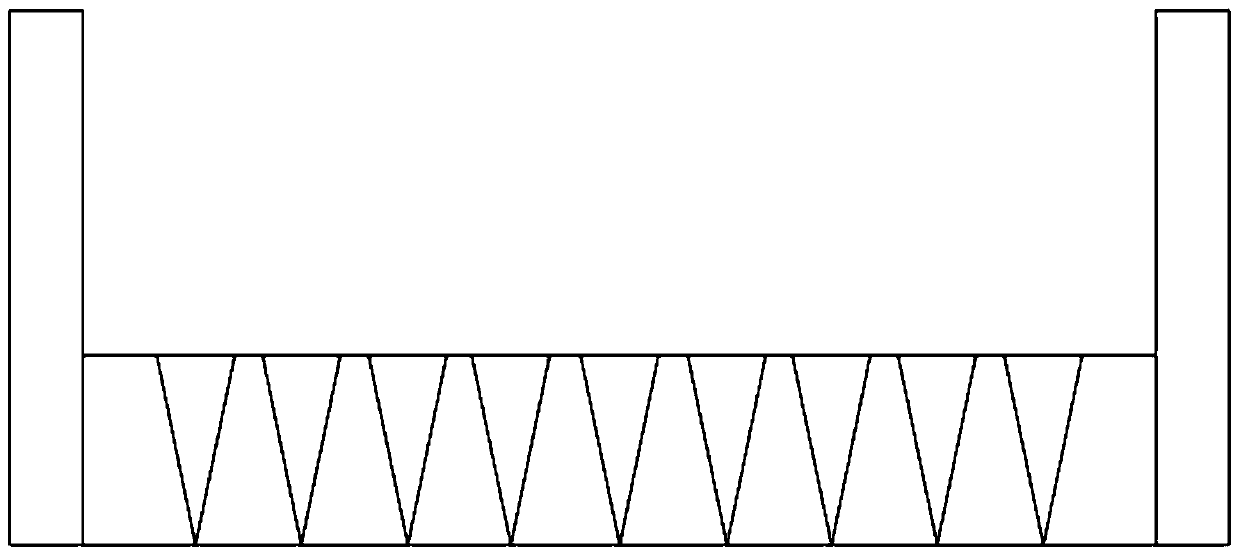

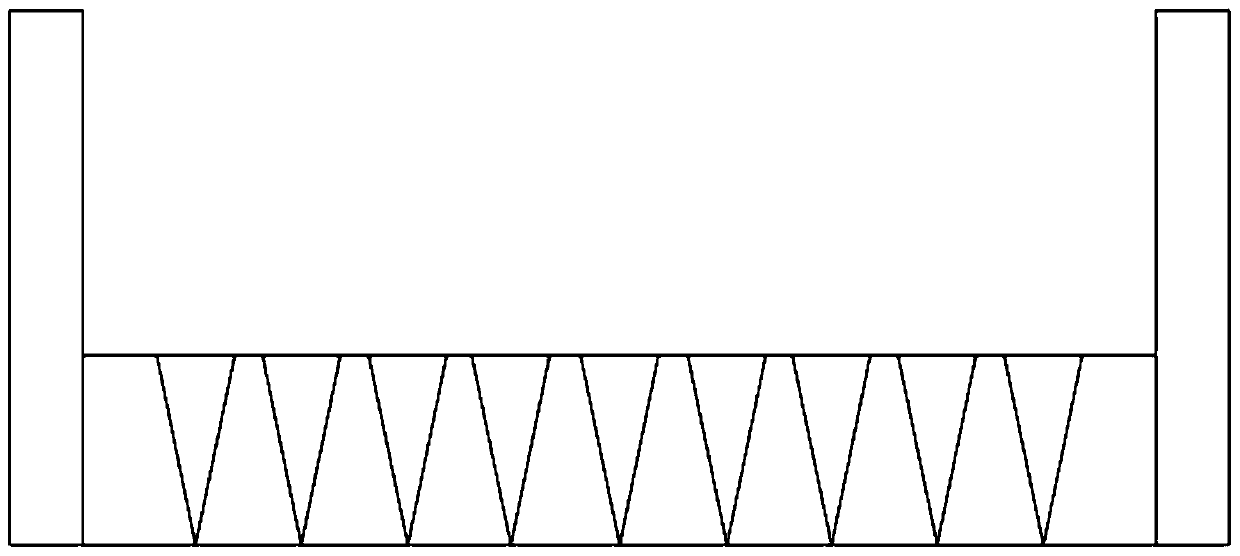

[0036] S2: Forming: Put the original slurry obtained in step S1 into a mold, the mold is a female mold with an array of microneedle-shaped depressions on the surface, and the density of the microneedle-shaped depressions is 200 pieces / cm 2 , the needle tip height of the microneedle is 450 μm, the mold is put ...

Embodiment 2

[0040] This embodiment provides a hyaluronic acid microneedle patch, which includes the following raw materials in parts by weight: 10 parts of hyaluronic acid, 0.1 part of collagen, 10 parts of glycerol, 6 parts of sodium ascorbyl phosphate, and 0.02 parts of benzisothiazolinone parts, 70 parts of deionized water.

[0041] The preparation method comprises the following steps:

[0042] S1: Preparing the original slurry: Weigh each raw material according to the ratio of parts by weight, put it into a vacuum emulsification pot, heat it to 45°C under stirring conditions, continue to stir until it dissolves evenly, and perform vacuum degassing treatment to obtain the original slurry;

[0043] S2: Forming: Put the original slurry obtained in step S1 into a mold, the mold is a female mold with an array of microneedle-shaped depressions on the surface, and the density of the microneedle-shaped depressions is 170 pieces / cm 2 , the needle tip height of the microneedle is 400 μm, the m...

Embodiment 3

[0047] This embodiment provides a hyaluronic acid microneedle patch, which includes the following raw materials in parts by weight: 1 part of hyaluronic acid, 0.5 part of collagen, 20 parts of butanediol, 2 parts of arbutin, 2 parts of sodium ascorbyl phosphate, formazan Base isothiazolinone 0.01 part, deionized water 60 parts.

[0048] The preparation method comprises the following steps:

[0049] S1: Preparing the original slurry: Weigh each raw material according to the proportion by weight, put it into a vacuum emulsification pot, heat it to 55°C under stirring conditions, continue stirring until it dissolves evenly, and vacuumize and defoam to obtain the original slurry;

[0050] S2: Forming: Put the original slurry obtained in step S1 into a mold, the mold is a female mold with an array of microneedle-shaped depressions on the surface, and the density of the microneedle-shaped depressions is 150 pieces / cm 2 , the tip height of the microneedle is 500 μm, the mold is put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com