Flexible clamp platform used for milling of gantry type five-coordinate metal plate numerical control milling machine

A CNC milling machine and flexible fixture technology, which is applied in clamping, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost of vacuum flexible fixtures built in CNC machine tools, affecting processing efficiency, processing costs, and long time-consuming cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

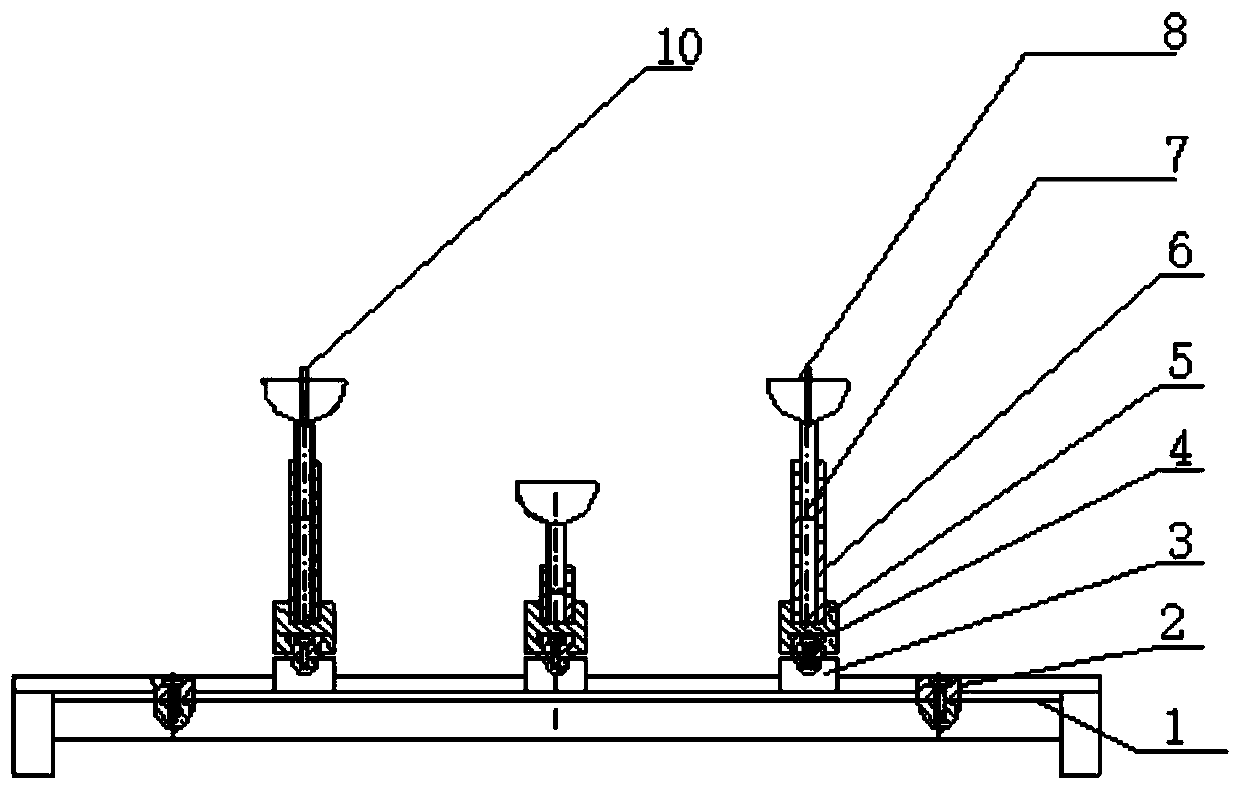

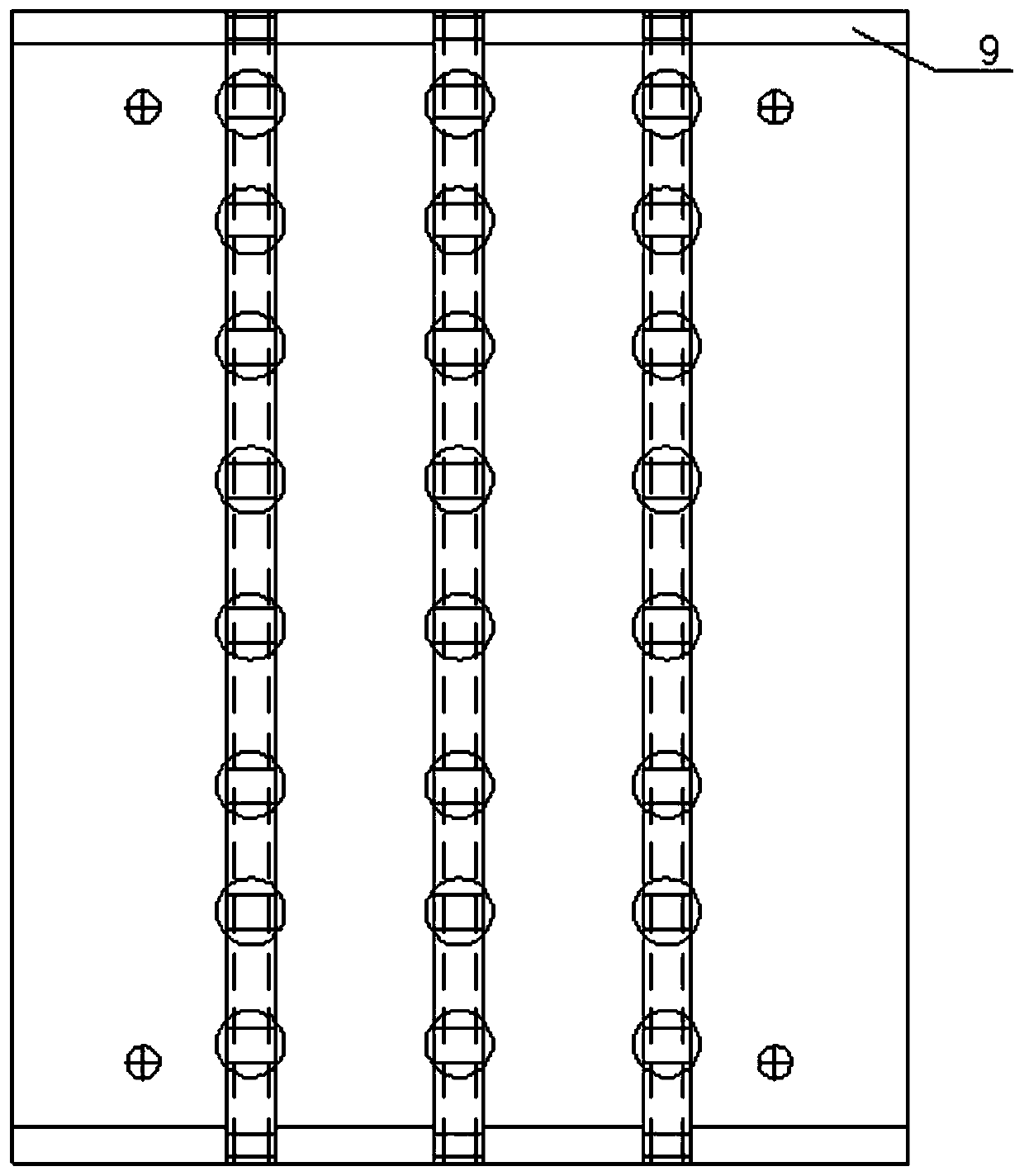

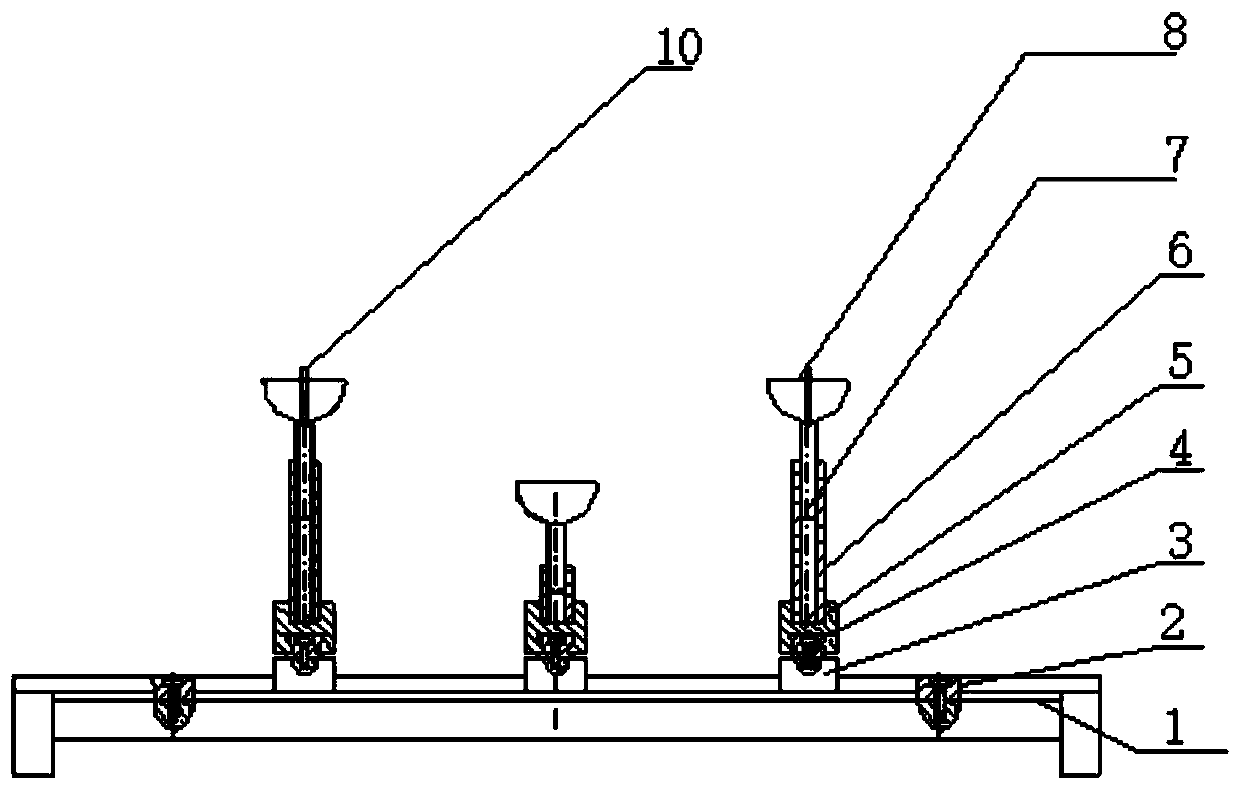

[0020] Such as figure 1 and figure 2 As shown, a flexible fixture platform for gantry-type five-coordinate sheet metal CNC milling machine milling, including a fixed base 1, a high-precision tool setting reference hole 2, a longitudinal slide bar 3, a longitudinal slide rail 4, a suction cup base 5, Pole support 6, pole 7, vacuum suction cup 8, transverse slide rail groove 9 and Φ5.2 pin 10;

[0021] The fixed base 1 is in the shape of a flat plate, placed on a five-coordinate machine tool platform, and fixed according to the machine tool coordinate system after finding the correct position; 4 high-precision tool setting reference holes 2 are drilled on the fixed base 1, and are inlaid. Used as a coordinate reference when milling the shape of the part, the five-coordinate machine tool can establish a coordinate sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com