Preparation method of graphene composite with high thermal conductivity

A technology of high thermal conductivity graphite and composite materials, which is applied in the field of preparation of high thermal conductivity graphene composite materials, can solve the problems of large amount of thermal conductive fillers and difficulty in forming thermal conduction paths, and achieve low equipment requirements, increased thermal conduction paths, and increased thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

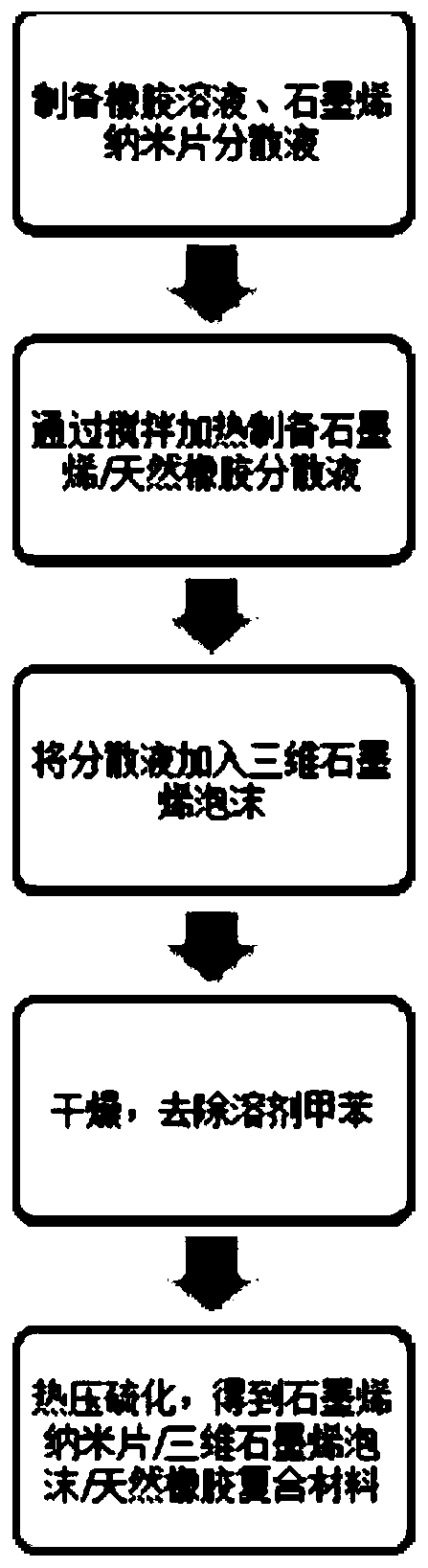

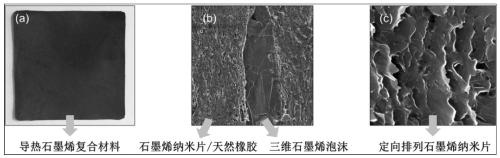

[0035] In the present embodiment, the preparation method of high thermal conductivity graphene composite material is as follows:

[0036]Take 80-150ml of toluene solvent and dissolve 3g of natural rubber under the condition of heating and stirring, the temperature is 40°C, the magnetic stirring rate is 300r / min, and the stirring time is 6h to form a natural rubber solution. Take 300-600 mg of graphene nanosheets, and disperse the graphene nanosheets in 60 ml of toluene by ultrasonic waves to form a graphene nanosheet dispersion. Add the graphene nanosheet dispersion into the natural rubber solution, heat and stir to obtain the graphene nanosheet / natural rubber dispersion, and add 0.03g stearic acid, 0.15g sulfur, 0.006g DM and 0.09g zinc oxide successively. The temperature is 60°C, the stirring rate is 800r / min, and the time is 12h.

[0037] Get 30ml graphene nanosheet / natural rubber dispersion and pour into the PTFE mold that three-dimensional graphene foam is housed, utiliz...

Embodiment 2

[0043] In the present embodiment, the preparation method of high thermal conductivity graphene composite material is as follows:

[0044] Take 90ml of toluene solvent and dissolve 3g of natural rubber under the condition of heating and stirring, the temperature is 40°C, the magnetic stirring rate is 200r / min, and the stirring time is 8h to form a natural rubber solution. Get 400mg of graphene nanosheets, and disperse the graphene nanosheets in 80ml toluene by ultrasonic waves to form a graphene nanosheet dispersion. Add the graphene nanosheet dispersion into the natural rubber solution, heat and stir to obtain the graphene nanosheet / natural rubber dispersion, and add 0.12g stearic acid, 0.15g sulfur, 0.021g DM and 0.09g zinc oxide successively. The temperature is 60°C, the stirring rate is 800r / min, and the time is 12h.

[0045] Get 25ml graphene nanosheet / natural rubber dispersion and pour into the PTFE mold that three-dimensional graphene foam is housed, utilize natural dry...

Embodiment 3

[0048] In the present embodiment, the preparation method of high thermal conductivity graphene composite material is as follows:

[0049] Take 120ml of toluene solvent and dissolve 3g of natural rubber under the condition of heating and stirring, the temperature is 40°C, the magnetic stirring rate is 300-600r / min, and the stirring time is 6-8h to form a natural rubber solution. Get 500mg of graphene nanosheets, and disperse the graphene nanosheets in 100ml toluene by ultrasonic waves to form a graphene nanosheet dispersion. Add the graphene nanosheet dispersion into the natural rubber solution, heat and stir to obtain the graphene nanosheet / natural rubber dispersion, and add 0.03g stearic acid, 0.12g sulfur, 0.021g DM and 0.24g zinc oxide successively. The temperature is 60°C, the stirring rate is 1000r / min, and the time is 12h.

[0050] Get 30ml graphene nanosheet / natural rubber dispersion liquid and add in the PTFE mold that three-dimensional graphene foam is housed, utiliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com