High-performance dynamically-vulcanized thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and dynamic vulcanization technology, applied in the field of polymer materials, can solve the problems of complex preparation process, poor mechanical properties, unfavorable application, etc., and achieve the effect of low raw material cost, improved air tightness, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

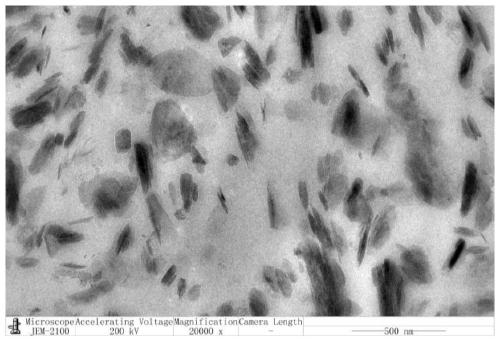

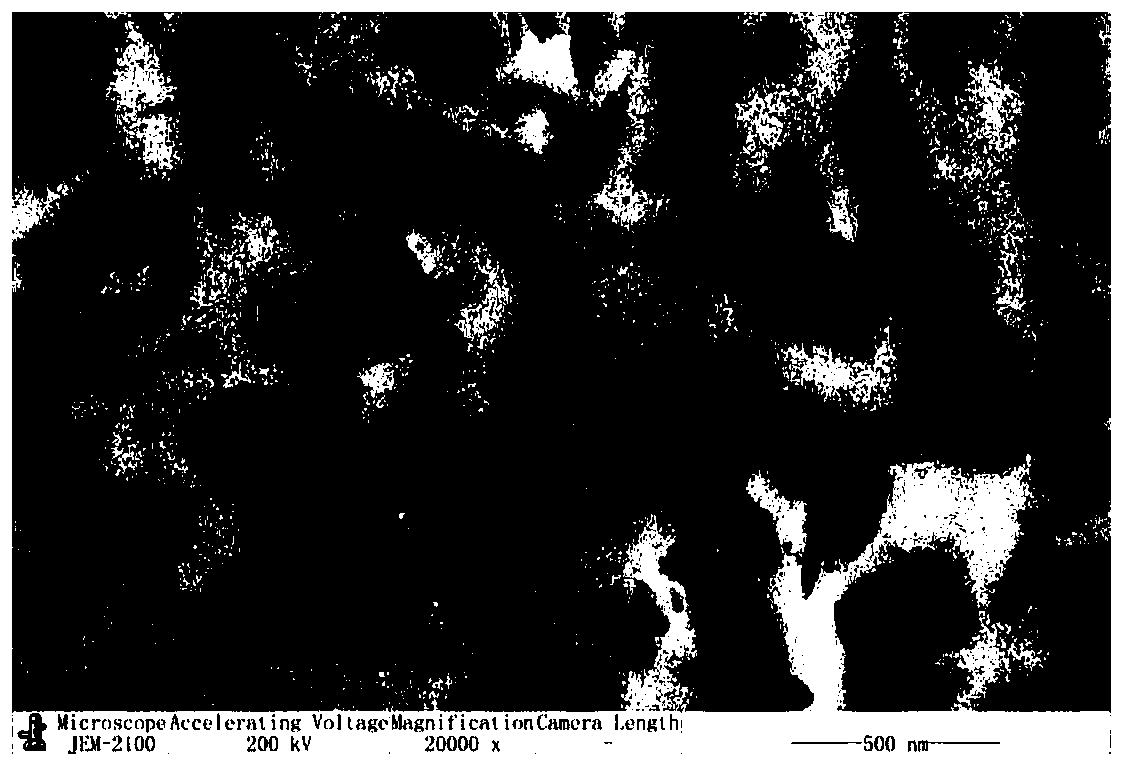

Image

Examples

preparation example Construction

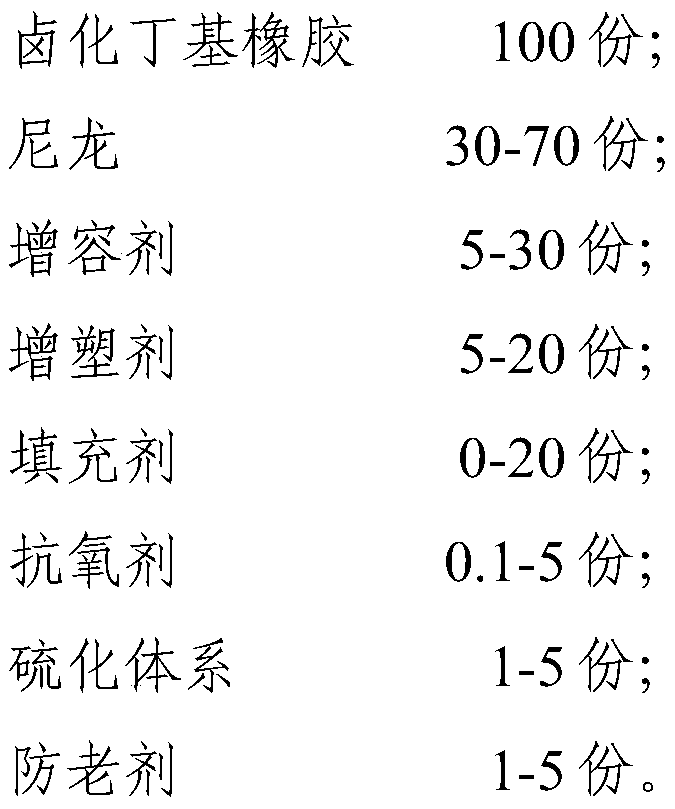

[0046] The preparation method of the above-mentioned high-performance dynamically vulcanized thermoplastic elastomer comprises the following steps:

[0047] (1) mixing halogenated butyl rubber with anti-aging agent, plasticizer, partial vulcanization system and filler to prepare masterbatch;

[0048] (2) Masterbatch is put into baking oven and carry out pre-vulcanization, obtains pre-vulcanized masterbatch;

[0049] (3) Add pre-vulcanized masterbatch, nylon, compatibilizer and antioxidant into the internal mixer and mix uniformly;

[0050] (4) Add the remaining vulcanization system into the internal mixer to prepare dynamically vulcanized thermoplastic elastomers.

[0051] Wherein, the partial vulcanization system used in the step (1) is 10-50% of the total vulcanization system quality, and masterbatch mixing is divided into two sections, and one section mixes halogenated butyl rubber, anti-aging agent, plasticizer, The filler is mixed, and the second stage is to mix the vul...

Embodiment 1

[0056] Embodiment 1: The rotation speed of the torque rheometer is set to 60 rpm, and the temperature is 50°C. Add bromobutyl rubber (100 parts), anti-aging agent 4020 (1.5 parts), and RD (0.5 parts) at 0 min; add epoxy soybean oil (6 parts) at 2 min; deglue at 5 min. The speed of the mill is set at 35 rpm, and the temperature of the roller is 30°C. A section of rubber compound, zinc oxide (1 part), insoluble sulfur (0.2 part) and accelerator M (0.1 part) are mixed in the milling process. Mixing and tableting are carried out on the machine, the thickness is 2mm, and it is parked at room temperature for 8-24h.

[0057] The temperature of the oven was set at 120° C., and the mixed masterbatch sheet was placed in the oven for pre-vulcanization for 8 minutes to obtain a pre-vulcanized masterbatch. The pre-vulcanized masterbatch was extruded and granulated to prepare pre-vulcanized masterbatch particles.

[0058] The pressure of the vacuum drying oven was set at -0.1Mpa, the tempe...

Embodiment 2

[0059] Embodiment 2: Different from Embodiment 1, the temperature of the oven is set to 130° C. in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com