Conveying belt marking high adhesive force color paste and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

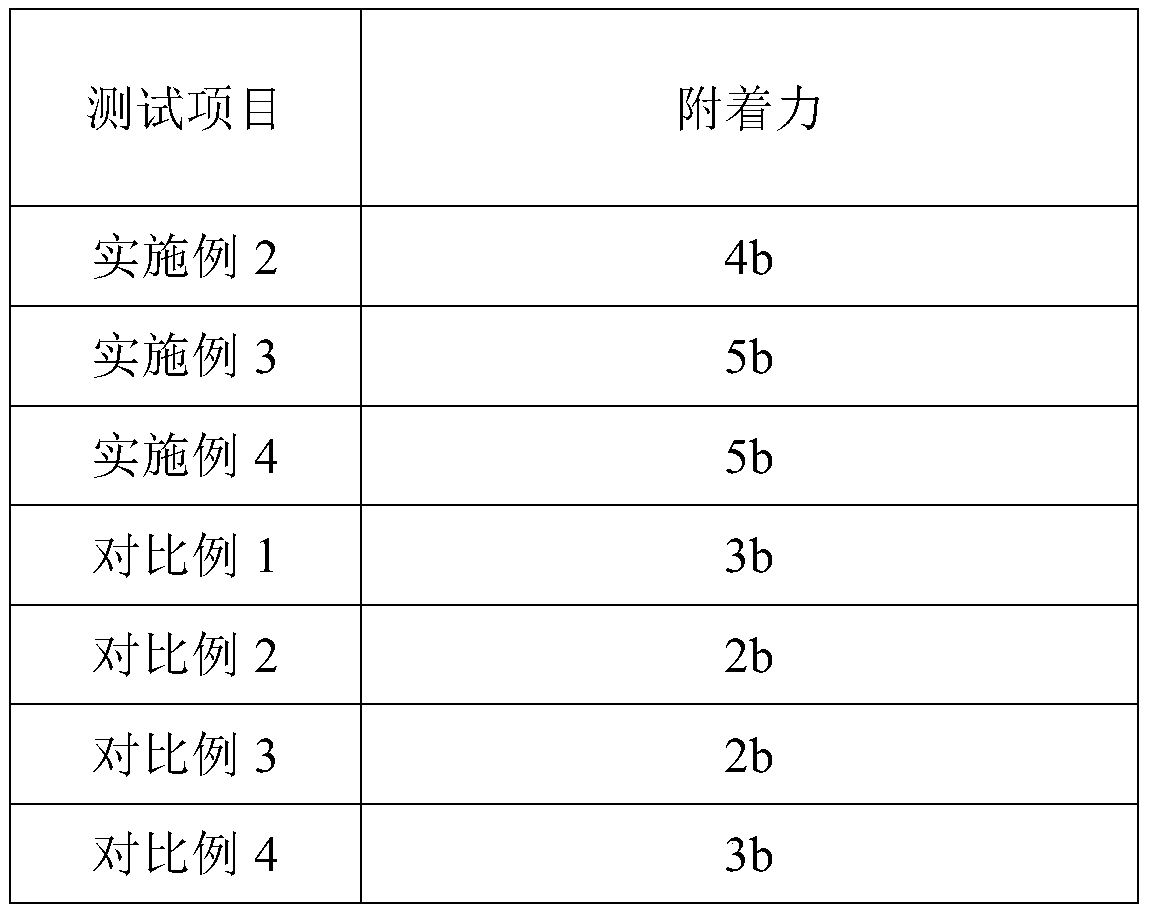

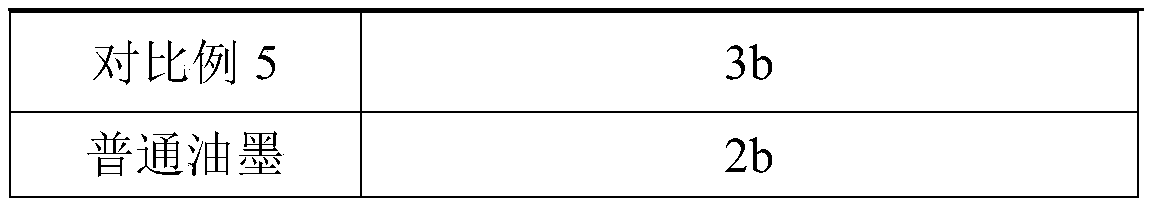

Examples

Embodiment 1

[0032] A high-adhesion color paste for conveyor belt marking, comprising A component and B component; the A component is made of the following raw materials in parts by weight: 44-48 parts of acetone, 42-45 parts of butanone solvent, 5-8 parts of polyurethane particles, 3-5.5 parts of benzimidazolone pigments;

[0033] The B component is made of the following raw materials in parts by weight: 100 parts of toluene diisocyanate, 35-45 parts of hexamethylene diisocyanate; when used, the weight ratio of component A and component B is 1:0.85-0.13 Mix well and serve.

Embodiment 2

[0035] A high-adhesion color paste for conveyor belt marking, including A component and B component; the A component is made of the following raw materials in parts by weight: 44 parts of acetone, 42 parts of butanone solvent, and 5 parts of polyurethane particles , 3 parts of benzimidazolone pigments;

[0036] The B component is made of the following raw materials in parts by weight: 100 parts of toluene diisocyanate, 35 parts of hexamethylene diisocyanate; when used, just mix the components A and B evenly according to the weight ratio of 1:0.85 .

[0037] In this embodiment, the polyurethane particles are Pearlstick 45-60 / 80 from Lubrizol Corporation of the United States.

[0038] In this embodiment, the toluene diisocyanate is Desmodur L67 from Bayer Company of Germany.

[0039] In this embodiment, the hexamethylene diisocyanate is CORONATE HX from Tosoh Corporation, Japan.

[0040] In this embodiment, the benzimidazolone pigment is benzimidazolone yellow H3G.

[0041] ...

Embodiment 3

[0049] A high-adhesion color paste for conveyor belt marking, including A component and B component; the A component is made of the following raw materials in parts by weight: 48 parts of acetone, 45 parts of butanone solvent, and 8 parts of polyurethane particles , 5.5 parts of benzimidazolone pigments;

[0050] The B component is made of the following raw materials in parts by weight: 100 parts of toluene diisocyanate, 45 parts of hexamethylene diisocyanate; when used, just mix the components A and B evenly according to the weight ratio of 1:0.13 .

[0051] In this embodiment, the polyurethane particles are Pearlstick 45-60 / 80 from Lubrizol Corporation of the United States.

[0052] In this embodiment, the toluene diisocyanate is Desmodur L67 from Bayer Company of Germany.

[0053] In this embodiment, the hexamethylene diisocyanate is CORONATE HX from Tosoh Corporation, Japan.

[0054] In this embodiment, the benzimidazolone pigment is benzimidazolone yellow H4G.

[0055...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com