Preheating starting method for vertical electrode aluminum electrolytic cell

A technology for preheating and starting an aluminum electrolytic cell, applied in the field of aluminum smelting, can solve problems such as unsuitability, achieve balanced distribution of cell voltage and current, and achieve the effect of non-disturbance start-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

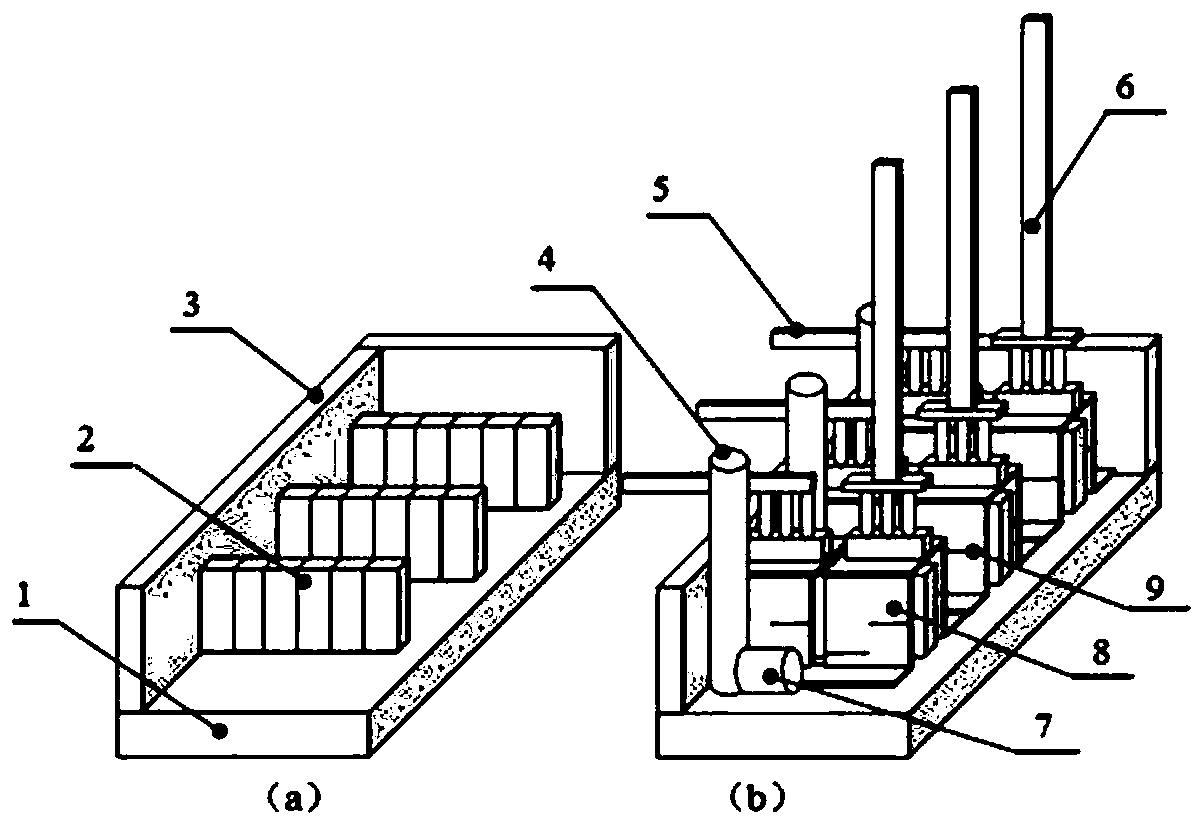

[0041] In this implementation, the structure of the electrolytic cell and the preheating roasting device is as follows: figure 1 shown.

[0042] The electrolytic cell is a 40kA inert anode aluminum electrolytic cell, figure 1 Shown as 1 / 4 slot. Each group of cathodes is 150cm long and 30cm high, and is composed of six small cathodes arranged side by side to form a wettable cathode-2. Each group of preheating roasting tubes is composed of a burner-4 and a burner nozzle-7, and the burner-4 and a cathode protection cover-8 are assembled in combination. Each cathodic protection shield has a negative lead-out bus bar-5 and a positive lead-out bus bar-6. The burner one 4, the burner nozzle one 7, and the cathode shield one 8 are all made of heat-resistant stainless steel (310s). There are several slits-9 on each group of cathodic protection covers, which are set for adjusting the resistance of the cathodic protection covers.

[0043] Each set of preheating and roasting tubes ha...

Embodiment 2

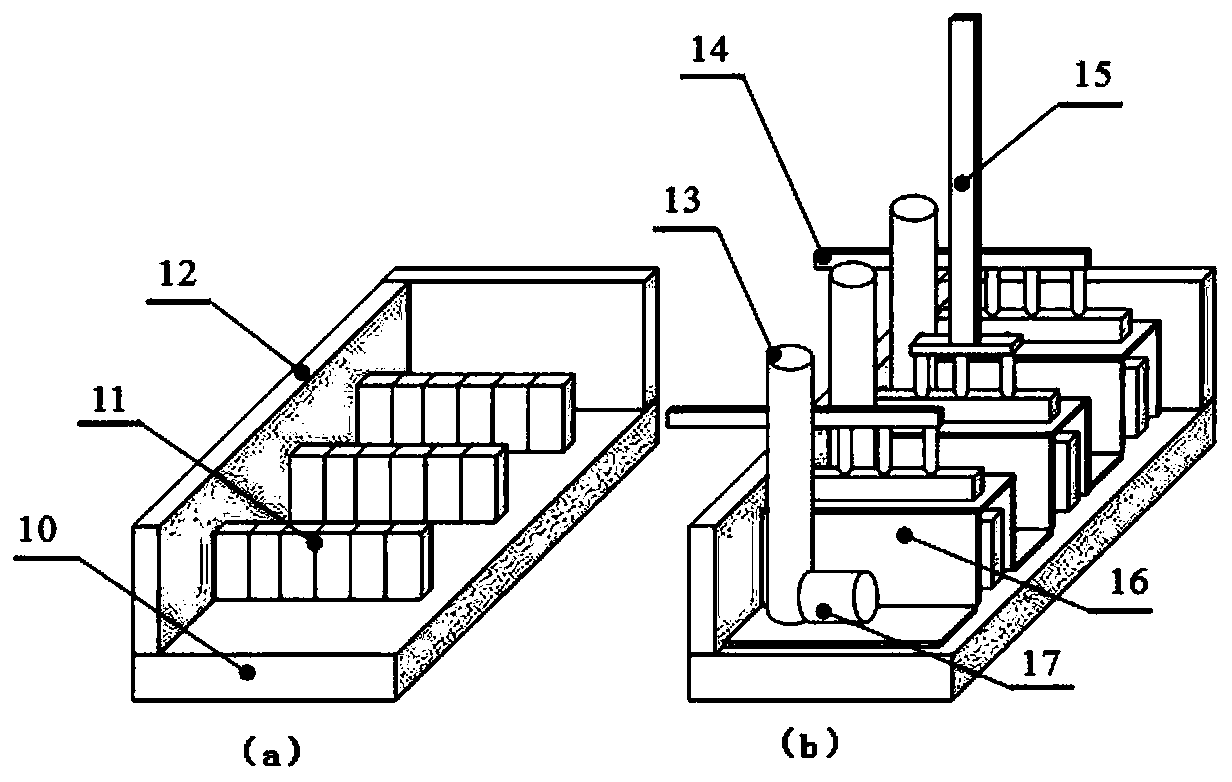

[0051] In this implementation, the structure of the electrolytic cell and the preheating roasting device is as follows: figure 2 shown.

[0052] The electrolytic cell is a 40kA inert anode aluminum electrolytic cell, figure 2 Shown as 1 / 4 slot. Each group of cathodes is 150cm long and 30cm high, and is composed of several small cathodes arranged side by side to form wettable cathodes 211. Each group of preheating roasting tubes is assembled by three burners two 13 and three burner nozzles two 17, three burners and the cathode protection cover two 16 that can protect three groups of cathodes. On the cathodic protection cover 2 16, there is a positive pole lead-out bus bar 2 15 and two negative pole lead-out bus bars 2 14. Burner 2 13, burner nozzle 2 17, and cathode shield 2 16 are all made of heat-resistant stainless steel (310s).

[0053] Each set of preheating and roasting tubes has its own heat-insulating and sealed cover, which can keep the electrolytic cell warm and...

Embodiment 3

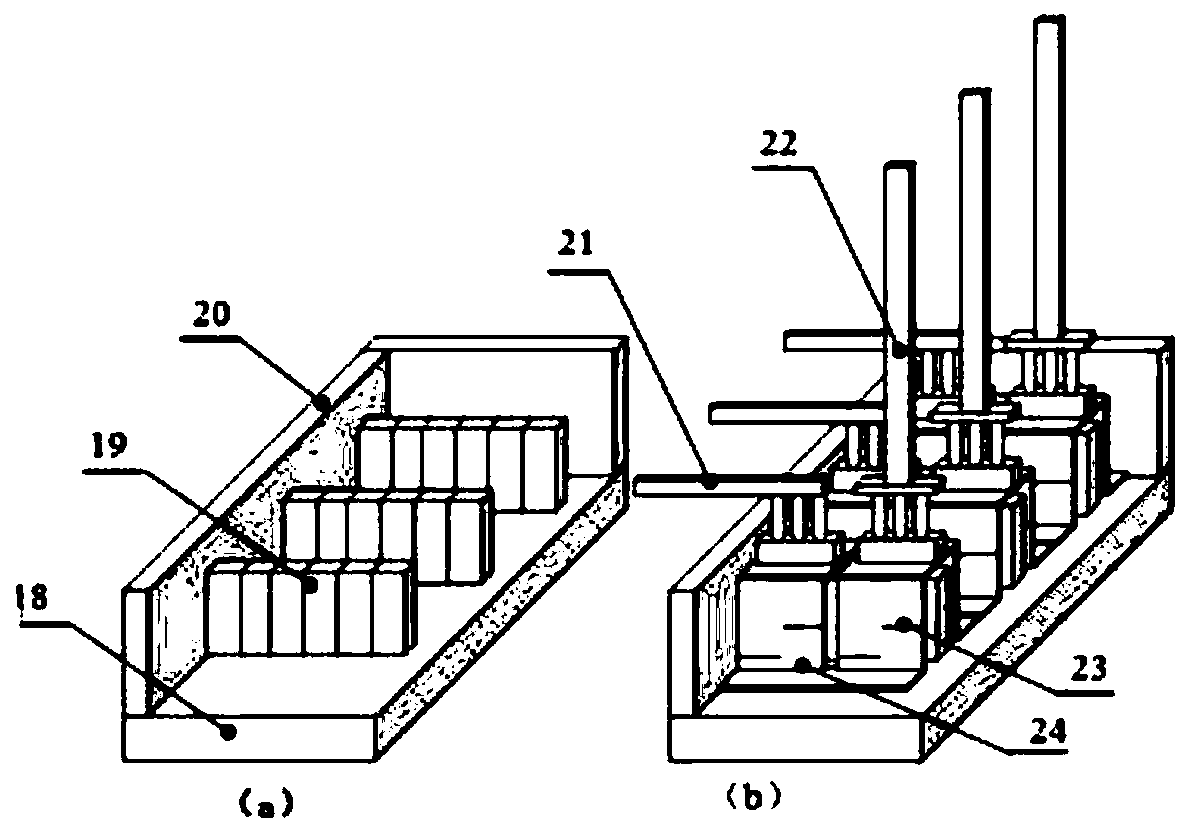

[0062] In this implementation, the structure of the electrolytic cell and the preheating roasting device is as follows: image 3 shown.

[0063] The electrolytic cell is a 40kA inert anode aluminum electrolytic cell, image 3 Shown as 1 / 4 slot. Each group of cathodes is 150cm long and 30cm high, and is composed of six small cathodes arranged side by side to form wettable cathodes 319. Each set of preheating roasting tubes has only one cathode protection cover 324 without a burner. Each cathode protection cover has a negative lead-out bus bar 3 21 and a positive lead-out bus bar 3 22 . The cathode protection cover 3 24 is made of heat-resistant stainless steel (310s). There are several slits 3 23 on each group of cathodic protection covers, which are set for adjusting the resistance of the cathodic protection covers.

[0064] Each set of preheating and roasting tubes has its own heat-insulating and sealed cover, which can keep the electrolytic cell warm and sealed during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com