High-whiteness low-temperature bleaching method for cashmere or wool

A technology with high whiteness and wool, applied in textiles and papermaking, etc., can solve the problems of insufficient whiteness, sour wool, and energy consumption of easy-to-damage cashmere, and achieve the effects of guaranteed source, improved whiteness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

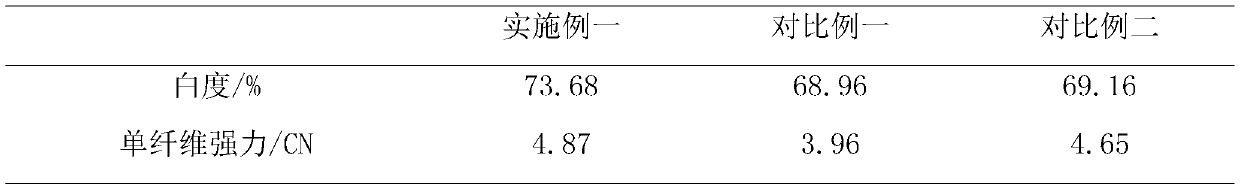

Embodiment 1

[0031] A high-whiteness low-temperature bleaching method for cashmere, using cashmere loose fiber as the cashmere product to be bleached, and performing the following steps in sequence:

[0032] Step a, preparing the activation solution: the activation solution includes 2 parts of penetrating agent, 1 part of activator and 7 parts of water;

[0033] Step b, preparing whitening solution: the whitening solution includes 2 parts of disperse chelating agent, 0.01 part of specific disperse dye and 7.99 parts of water;

[0034] Step c, soak the cashmere to be bleached in the bleaching working solution, the mass ratio of the cashmere or wool to be bleached and the bleaching working solution is 1:20, the bleaching working solution includes whitening solution, activation solution, hydrogen peroxide, compound alkali agent, press Process curves are bleached and then dried. Add whitening solution, activation solution, hydrogen peroxide, and compound alkali agent in sequence and mix them ...

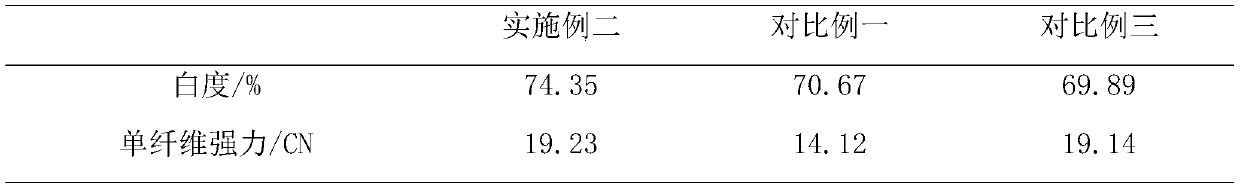

Embodiment 2

[0046] A high-whiteness low-temperature bleaching method for wool, using loose wool fibers as the wool to be bleached, and performing the following steps in sequence:

[0047] a. Preparation of activator: consisting of 2 parts of penetrant JFC, 2 parts of activator and 6 parts of water;

[0048] b. Preparation of disperse whitening agent: whitening solution composed of 2 parts of dispersing chelating agent, 0.01 part of specific disperse dye and 7.99 parts of water;

[0049] c. With the mass ratio of the wool to be bleached and the bleaching working solution at 1:20, put in the activator, brightener, hydrogen peroxide, and compound alkali agent in sequence to immerse the wool to be bleached in the above bleaching working solution, and proceed according to the process curve drying after bleaching;

[0050] Further, the activator in the bleach solution in step a is sodium nonanoylbenzenesulfonate, the English name NOBS.

[0051] Further, the specific disperse dye in the step b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com