Power battery pre-heating method

A power battery and preheating technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of large heat loss, low heating efficiency, and increased burden on electric vehicles, and achieves a simple implementation method, low cost, and high heating efficiency. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

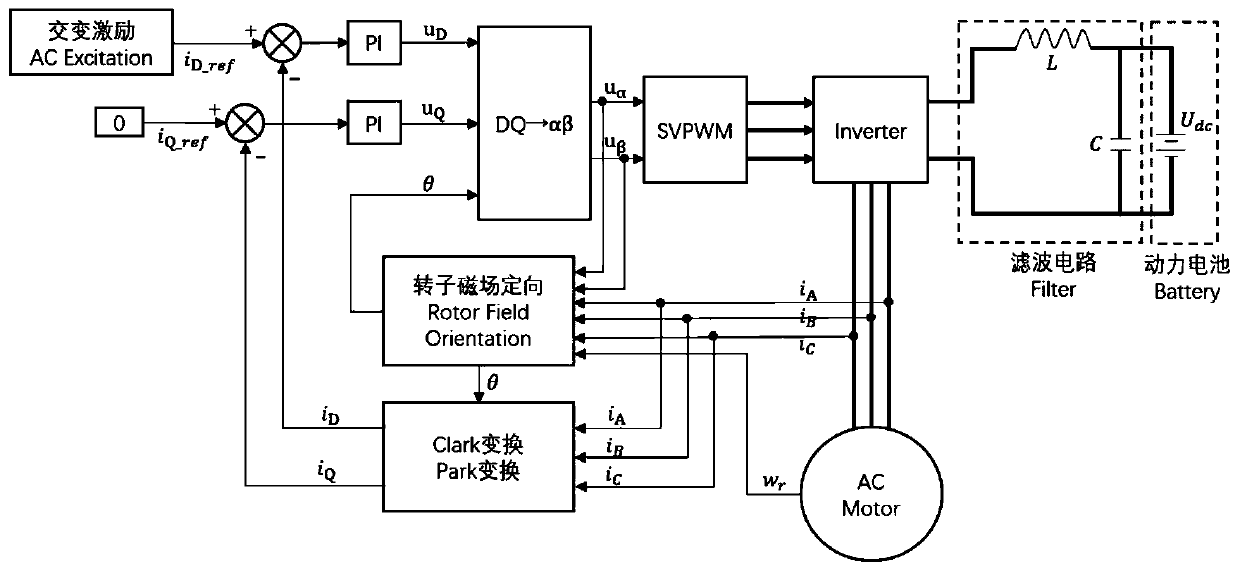

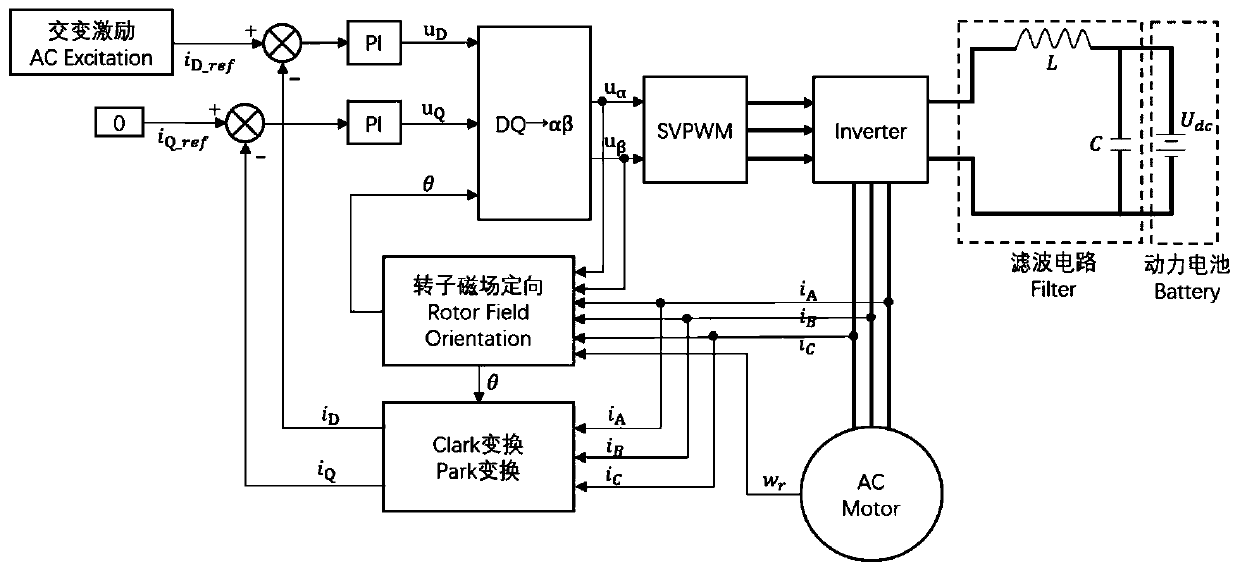

[0028] combine figure 1 Shown is a schematic diagram of the power battery preheating system provided by the present invention; wherein, the rotor magnetic field is oriented by detecting the stator three-phase current, stator voltage, motor speed, and rotor position information of the vehicle AC drive motor. If the AC drive motor for vehicles is a permanent magnet synchronous motor, the position of the rotor magnetic field is measured or estimated through position detection devices such as resolvers or the monitoring values of sensors such as stator voltage and current; if the AC drive motor for vehicles is an AC asynchronous motor, the stator The voltage, current, and speed information are combined with a voltage-current model or a current-speed model to estimate the direction of the rotor magnetic field.

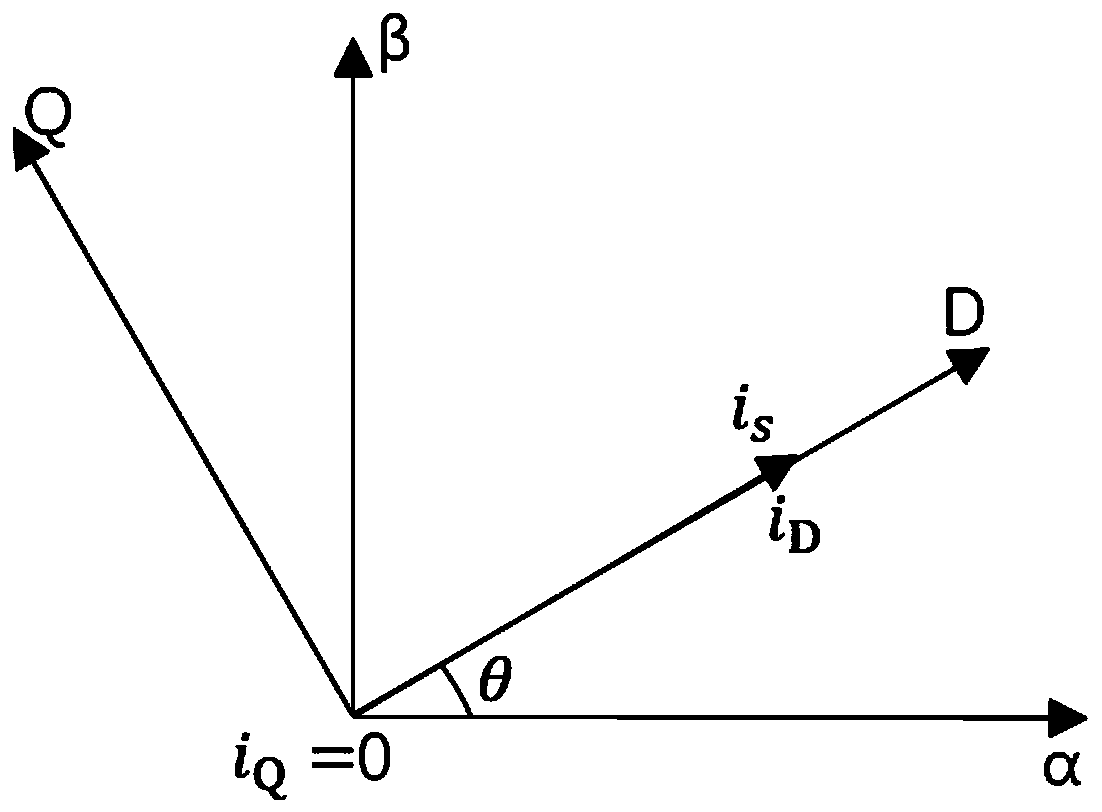

[0029] Establish a rotor magnetic field orientation synchronously rotating Cartesian coordinate system, in which the D axis is along the direction of the rotor magnetic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com