Elliptical waveguide load

An elliptical waveguide and waveguide cavity technology, which is applied to waveguide devices, electrical components, circuits, etc., can solve the problems of increasing the complexity of components, and achieve the effects of saving installation space, excellent VSWR performance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

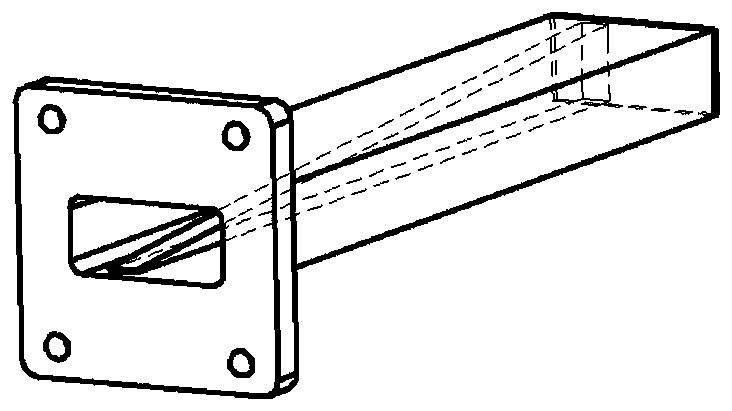

[0030] 1) Structure: The elliptical waveguide load is composed of a flange 1, a waveguide cavity 2, an absorber 3 and a tail cover 4. The cross section of the waveguide cavity 2 is elliptical, and the absorber 3 is a cone. The angle is 5°, and the length of the absorber 3 is taken as 2 times of λ / 2.

[0031] 2) Material: the flange, the waveguide cavity and the tail cover are made of duralumin LY12; the absorber is made of bakelite; the outer surface of the elliptical waveguide load is anodized.

[0032] 3) Dimensions: the ratio of the minor axis to the major axis of the elliptical section of the waveguide cavity 2 is 0.45.

[0033] 4) Assembly: the flange is connected to one end of the waveguide cavity by silver soldering; the conical bottom surface of the absorber is connected to the tail cover through adhesive, and the sticking position should be slightly away from the left side of the center of the tail cover by 5mm; the tail cover after the glue is completed The plate is...

Embodiment 2

[0036] 1) Structure: The elliptical waveguide load is composed of a flange 1, a waveguide cavity 2, an absorber 3 and a tail cover 4. The cross section of the waveguide cavity 2 is elliptical, and the absorber 3 is a cone. The angle is 15°, and the length of the absorber 3 is taken as 4 times of λ / 2.

[0037] 2) Material: The flange, waveguide cavity and tail cover are made of environmentally friendly copper (C3604), and the outer surface is nickel-plated; the absorber is made of conductive fiber.

[0038] 3) Dimensions: the ratio of the minor axis to the major axis of the elliptical section of the waveguide cavity 2 is 0.65.

[0039] 4) Assembly: The flange is connected to one end of the waveguide cavity by silver soldering; the conical bottom surface of the absorber is connected to the tail cover through adhesive, and the sticking position should be slightly away from the right side of the center of the tail cover by 8mm; the tail cover after the glue is completed The plate...

Embodiment 3

[0041] 1) Structure: The elliptical waveguide load is composed of a flange 1, a waveguide cavity 2, an absorber 3 and a tail cover 4. The cross section of the waveguide cavity 2 is elliptical, and the absorber 3 is a cone. The angle is 30°, and the length of the absorber 3 is taken as 8 times of λ / 2.

[0042] 2) Material: the flange 1, the waveguide cavity 2 and the tail cover 4 are made of brass (H62), and the outer surface is painted; the absorber is made of sponge soaked in carbon powder.

[0043] 3) Dimensions: The ratio of the minor axis to the major axis of the elliptical section of the waveguide cavity 2 is 0.52.

[0044] 4) Assembly: The flange is connected to one end of the waveguide cavity by silver soldering; the conical bottom of the absorber is connected to the tail cover through adhesive, and the sticking position should be slightly off the right side of the center of the tail cover by 10mm; the tail cover after the glue is completed The plate is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com