Power cable bridge inspection system

A technology of cable bridge and inspection system, which is applied in the direction of cable installation, cable installation device, electrical components, etc., to achieve the effect of ensuring long-term smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

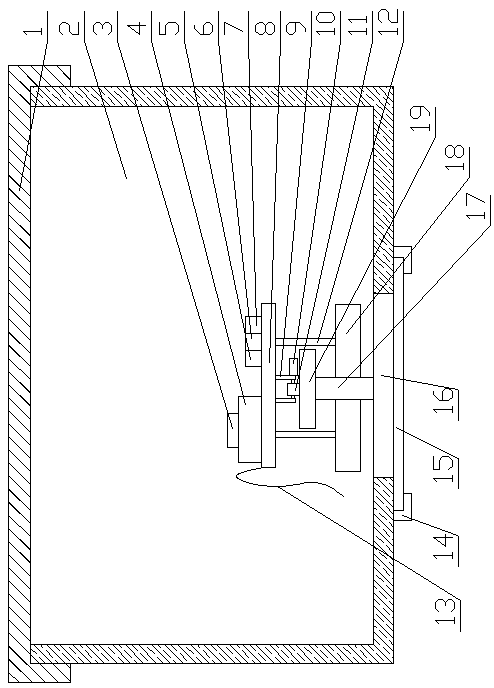

Embodiment 1

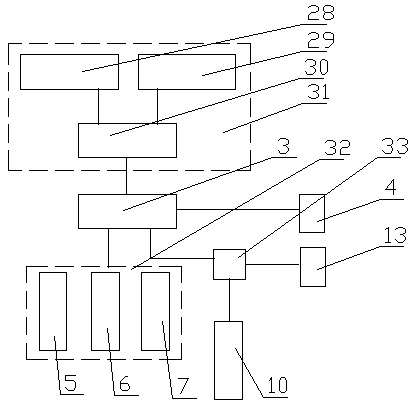

[0029] Embodiment 1, this embodiment provides a power cable bridge inspection system, including a bridge mechanism, a cover opening mechanism arranged on the bridge mechanism, a track mechanism arranged in the bridge mechanism, and an inspection mechanism arranged on the track mechanism And a retractable mechanism for setting out the inspection mechanism; the inspection mechanism includes a mobile base arranged on a track mechanism, and a control mechanism 3, a power supply mechanism and a monitoring mechanism 32 are set on the mobile base, and the control mechanism 3 and monitoring center 31 communication connection. The opening mechanism is convenient to open an operation hole to operate the inspection system. After the inspection is completed, the opening mechanism can be closed again to prevent small animals and dust from entering. The track mechanism is convenient for the inspection mechanism to guide and move in the bridge mechanism, and the retractable mechanism is to r...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is:

[0035] The control mechanism 3 includes a microcontroller, the power supply mechanism includes a lithium battery 4 that supplies power to the control mechanism 3 and a power supply line 13 that supplies power to the drive motor 10, and the monitoring mechanism 32 includes a temperature and humidity sensor 5, a smoke sensor 6, Infrared camera 7 ; the control mechanism 3 is connected with the monitoring mechanism 32 and the drive motor 10 , and the power supply mechanism is connected with the control mechanism 3 and the drive motor 10 . The microcontroller is a single-chip microcomputer that integrates the main part of the microcomputer on a chip, which can meet the control requirements of the scene. The lithium battery supplies power to the control mechanism and the monitoring mechanism, and its power consumption is very small, and the battery can provide enough electric energy. The driving motor consumes a l...

Embodiment 3

[0037] The difference between this embodiment and Embodiment 1 is:

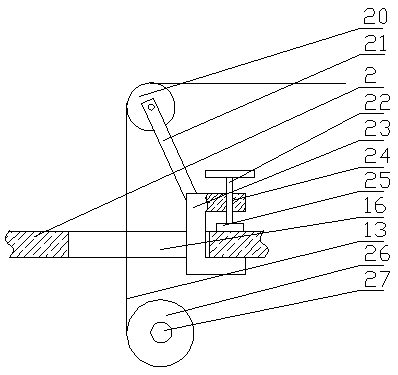

[0038] The monitoring center 31 includes a PLC controller 30 connected to the control mechanism 3 by wires, and the PLC controller 30 is connected with an operation button 28 and a display 29 . The monitoring center is on site for the staff to control the inspection agency, and at the same time display the information detected by the inspection agency. Its preferred PLC controller is a digital electronic device with a microprocessor, a digital logic controller for automatic control, and can load control instructions into the memory for storage and execution at any time. Of course, you can also directly modify the notebook as the control center.

[0039] The retracting mechanism includes a bobbin 26 and a bobbin 27 disposed on the bobbin 26 , and the power supply line 13 is wound on the bobbin 27 . The retracting mechanism is to wind and retract the power supply lines and communication lines to avoid too muc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com