A uniform feeding device for oblique shallow sedimentation thickener with half-type slag separator

A technology of feeding device and thickener, which is applied to the feeding/discharging device of the settling tank, sedimentation separation, chemical instruments and methods, etc., which can solve the problems of effective performance and stable operation, inconsistent working state of the settling mold, etc. that affect the performance of the equipment. It can not give the distribution of ore slurry and other problems, so as to achieve the effect of simple structure, stable operation and effective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

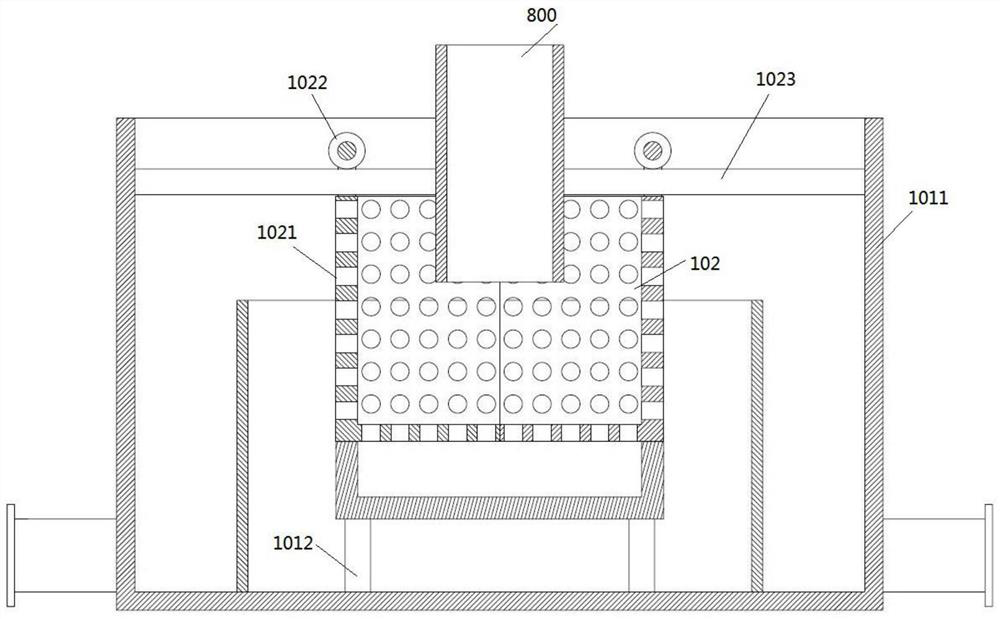

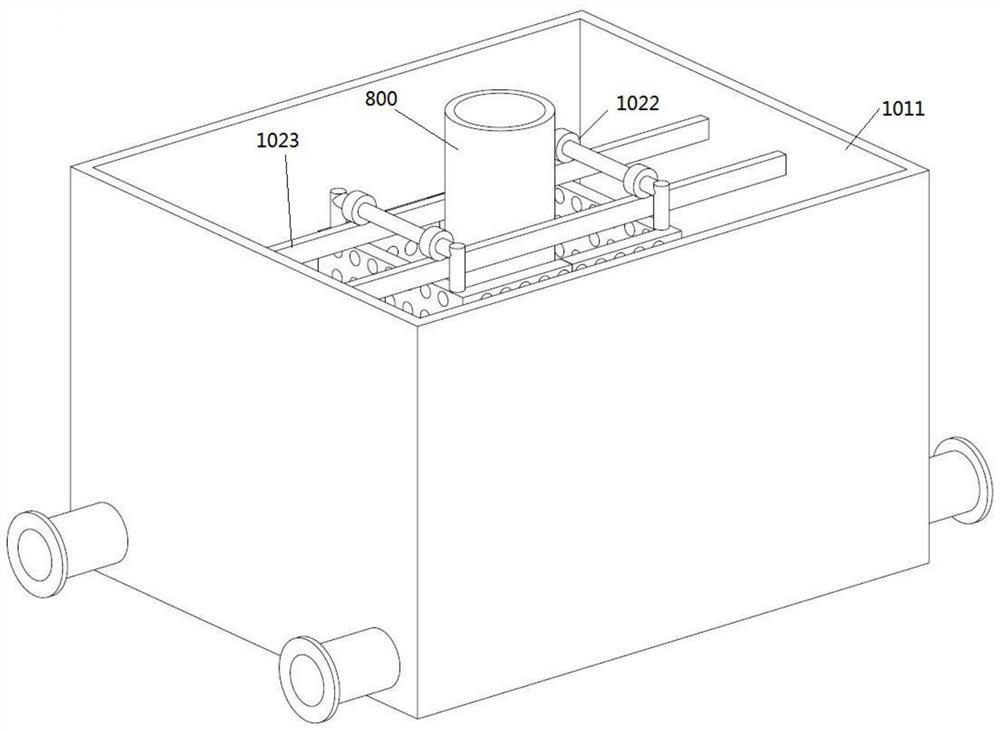

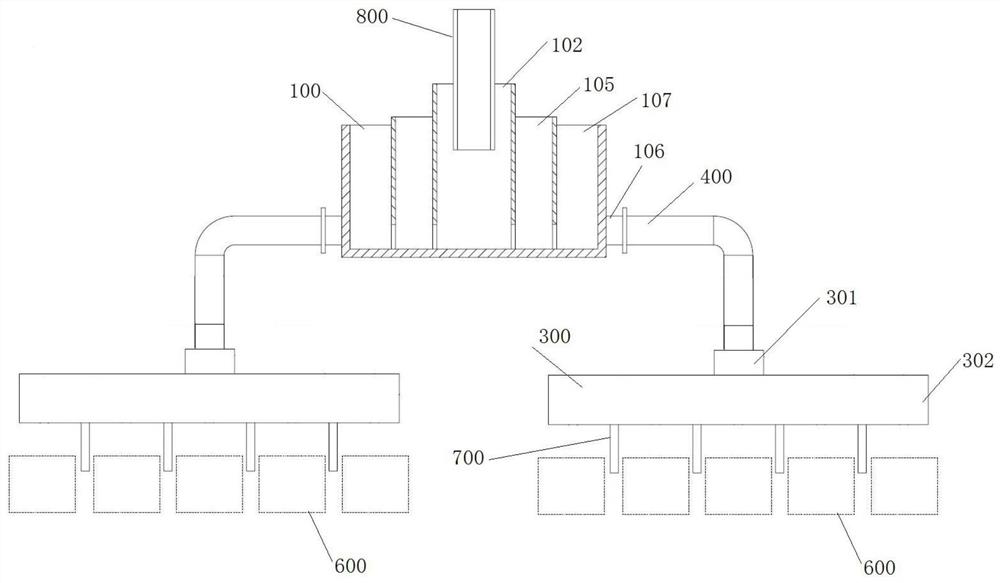

[0042] In a polymetallic sulfide ore dressing plant, ZXN-500 vibrating inclined plate settlement thickener is used for unilateral ore feeding. In the concentration of the middle ore after tin selection, use a ZXN-500 vibrating sloping plate oblique shallow layer thickener for concentration. The equipment has a total of 10 inclined plate settling modules, two cone buckets discharge underflow, and uses a set of uniform feeding device of the present invention.

[0043] In the first-stage feeding unit 100, the shape of the feeding box 101 is a cuboid, and its length, width and height are 1000×500×1200mm. The interior is divided into sieve-type slag separators 102 by partitions of different heights. , the middle tank 105 and the ore-distributing channel 107. The length, width and height of the sieve-type slag separator 102 are 500×500×1000 mm, which is a complete through trough, and no isolation is required inside; the length, width and height of the middle tank 105 are 800×500×60...

Embodiment 2

[0048] In an iron ore concentrator, a ZXN-2400 vibration-type oblique box oblique shallow layer thickener is used to concentrate the fine-grained ore pulp in the tailings dry-drainage and heap concentration. The equipment has a total of 48 inclined box settling modules, eight cone buckets discharge the underflow, and two sets of uniform feeding devices with half-type slag separators of the present invention are used.

[0049] In the first-stage feeding unit 100, the shape of the ore feeding box 101 is a cuboid, and the length, width, and height dimensions are 1000×500×1200 mm. Sieve-type slag separator 102, in which wear-resistant material boards are laid to prevent the impact of ore pulp; outside the sieve-type slag separator 102, a middle tank 105 with a length, width and height of 800×500×600mm is set outside the middle tank 105 There is a mine-dividing channel 107 whose length, width and height are 1000×500×600mm. The sieve-type half-type slag separator 102 is made of wea...

Embodiment 3

[0054] An iron ore dressing plant contains a certain amount of phosphate ore, and the slurry needs to be concentrated and deslimed before the iron ore tailings are selected for phosphorus. A ZXN-1200 vibrating inclined box inclined shallow layer thickener is used to deslim the fine-grained ore pulp. The equipment has a total of 24 inclined box settling modules, four cone buckets discharge the underflow, and uses a set of uniform feeding device of the present invention.

[0055] In the first stage feeding unit 100, the profile of the ore feeding box 101 is a cylinder, and the external dimensions of a single device are Set the diameter at the middle position inside the mine box 101 to A sieve-type slag trap 102 with a height of 1200 mm. The sieve-type slag trap 102 is composed of two semicircular half-shaped slag traps 1021. The half-shaped slag trap is made of PE pipes. 103 and the bottom is opened with a diameter of hole. Outside the sieve type slag separator 102, the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com