A Method for Controlling Dimensional Accuracy of Wire Rod Rolling

A dimensional accuracy, wire rod rolling technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of dimensional accuracy fluctuation, yield loss, drawing steel necking, etc., to reduce rolling breakage , the effect of stabilizing rolling production and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

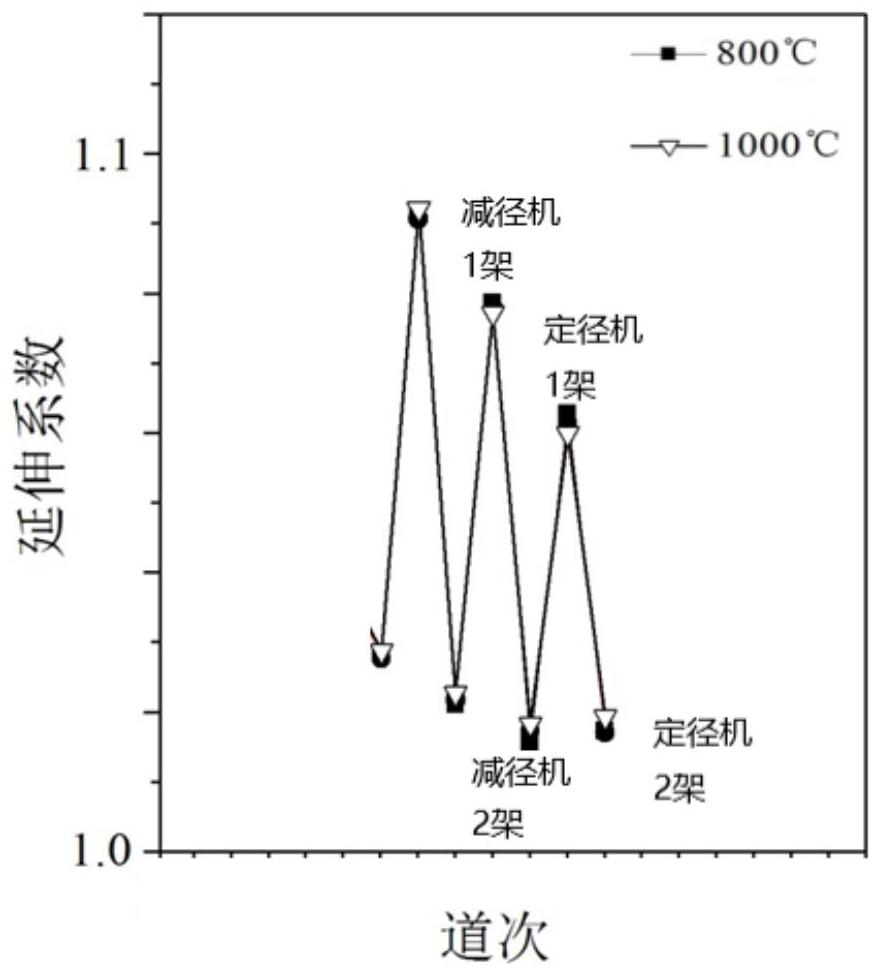

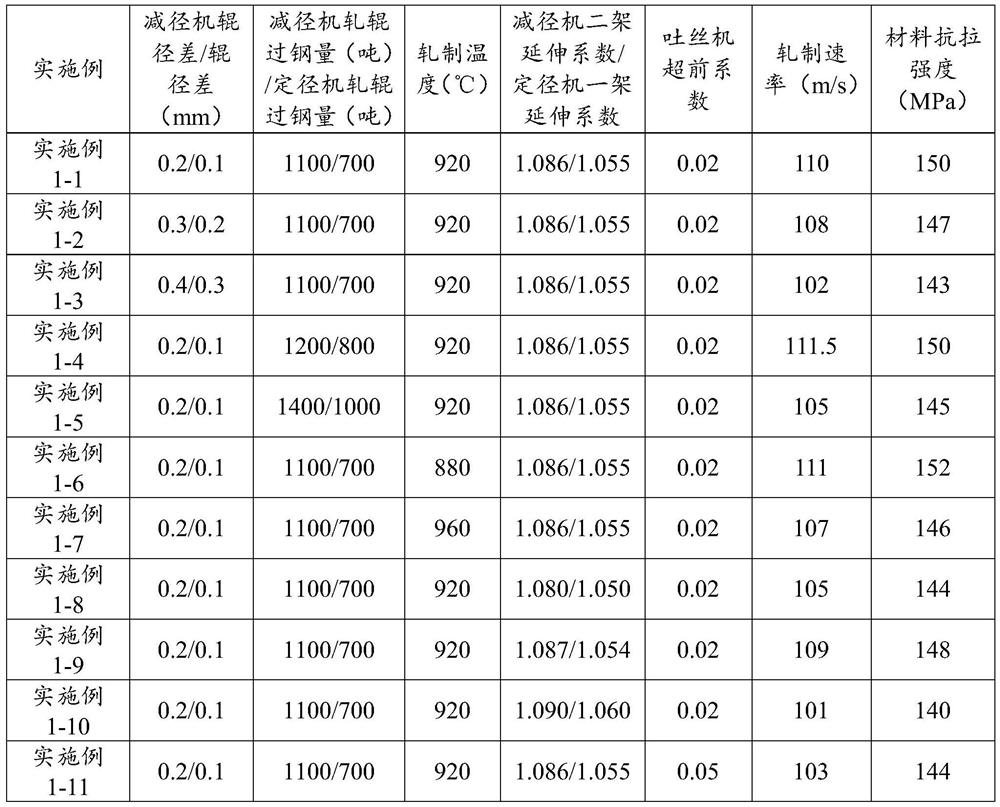

Embodiment 1

[0071]Using the method of the present invention for production In the welding line ER70S-6, the roll diameter difference of the first reducing machine and the second reducing machine before the control product is 0.2mm, and the roll diameter difference of the first sizing machine and the second sizing machine is 0.1. mm. Control the roll diameter ratio of the reducing and sizing mill, and the roll diameter ratio of two adjacent reducers and one sizing machine is 220 / 150. Reasonably control the amount of steel passing through the rolls and guides. The amount of steel passing through the rolls of the reducer should not exceed 1,100 tons, the amount of steel passing through the rolls of the sizing machine should not exceed 700 tons, and the guide time should be 3 hours. The temperature of reducing and sizing rolling in the first four frames of the finished product is controlled at 920 ° C, and the tensile strength of the material is 150 MPa at this temperature. The extension c...

Embodiment 2

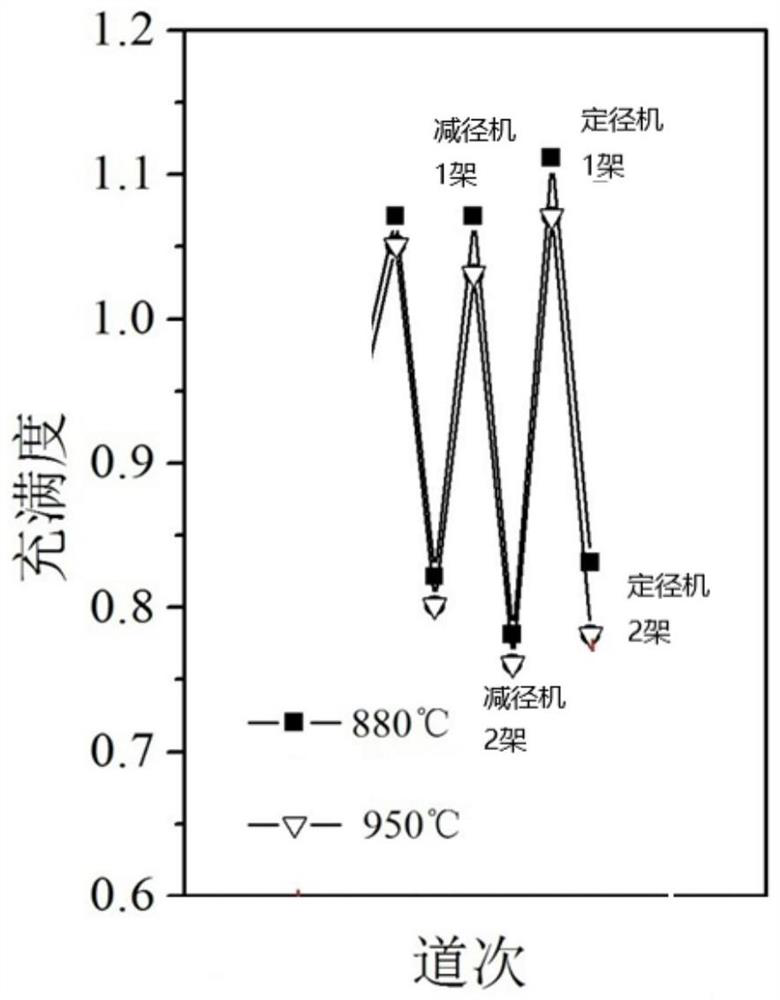

[0076] Using the method of the present invention for production In the welding line 82A, the roll diameter difference of the first reducing machine and the second reducing machine before the control product is 0.1mm, and the roll diameter difference of the first sizing machine and the second sizing machine is 0.1mm. Control the roll diameter ratio of the reducing and sizing mill before the finished product, and the roll diameter ratio of two adjacent reducers and one sizing machine is 220.2 / 150.1. Reasonably control the amount of steel passing through the rolls and guides. The amount of steel passing through the rolls of the reducer should not exceed 1200 tons, and the amount of steel passing through the rolls of the sizing machine should not exceed 800 tons. The tensile strength of the material at this temperature is 170MPa, and the guide time is 3 hours. The reducing and sizing rolling temperature of the first four frames of the finished product is controlled at 880°C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com