Spinning three-dimensional weaving equipment for continuous ceramic filaments

A three-dimensional weaving and ceramic technology, which is applied in the direction of braided fabrics, textiles, papermaking, yarn, etc., can solve the problems of easy fracture under force and high brittleness of oxide ceramic filaments, and achieve the effect of solving tension instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

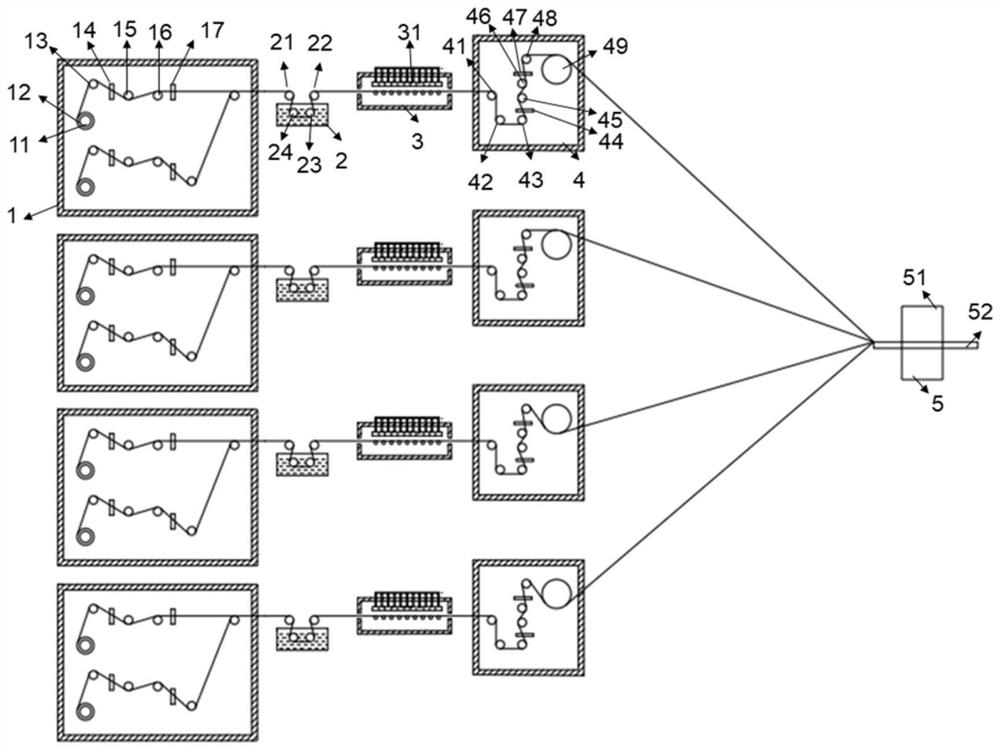

[0036] This embodiment provides a spinning and three-dimensional weaving equipment for continuous ceramic filaments, which mainly includes: a yarn unwinding mechanism 1 , an oiling device 2 , a drying device 3 and a constant tension device 4 .

[0037] The spinning mechanism 1 specifically includes a first spinning roller 11 , a ceramic continuous filament package 12 , a steering column 13 , a tension sensor 14 , a first tension roller 15 , a first compensation roller 16 , and a tension sensor 17 . The ceramic continuous filament package 12 is fixed on the first pay-off roller 11, and the ceramic continuous filament passes through the steering column 13, the tension sensor 14, the first tension roller 15, the first compensation roller 16, and the tension sensor 17 to the oiling device 2. . The linear speed of the first pay-off roller 11 is V 1 , the speed of the first tension roller 15 is V 2 , the speed of the first compensation roller 16 is V 3 , in order to ensure that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com