Low-frequency vibration cutting chip breaking device

A vibrating cutting, low-frequency vibration technology, applied in the direction of fluid using vibration, turning equipment, tool holder accessories, etc., can solve the problems of high cost, large volume, difficulty in adjusting amplitude and frequency, and achieve low cost and interchangeability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

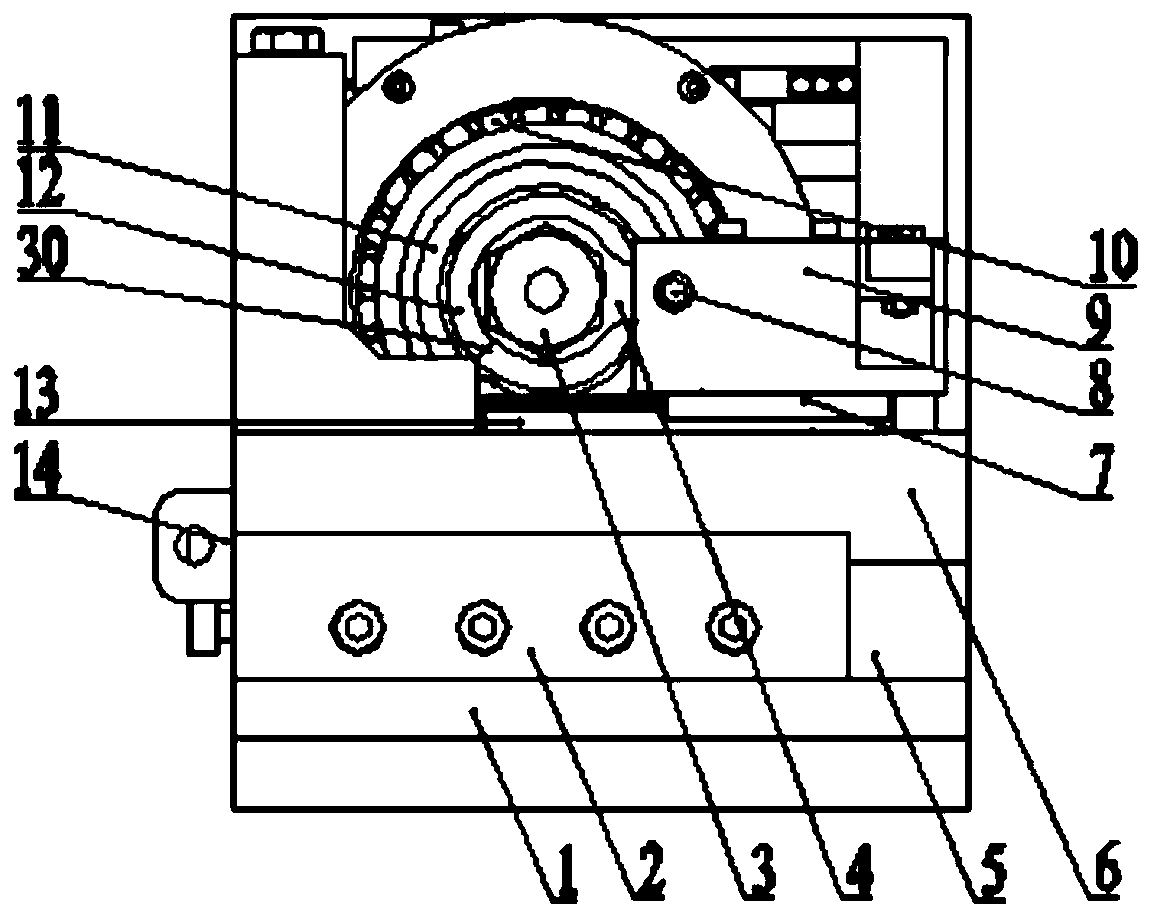

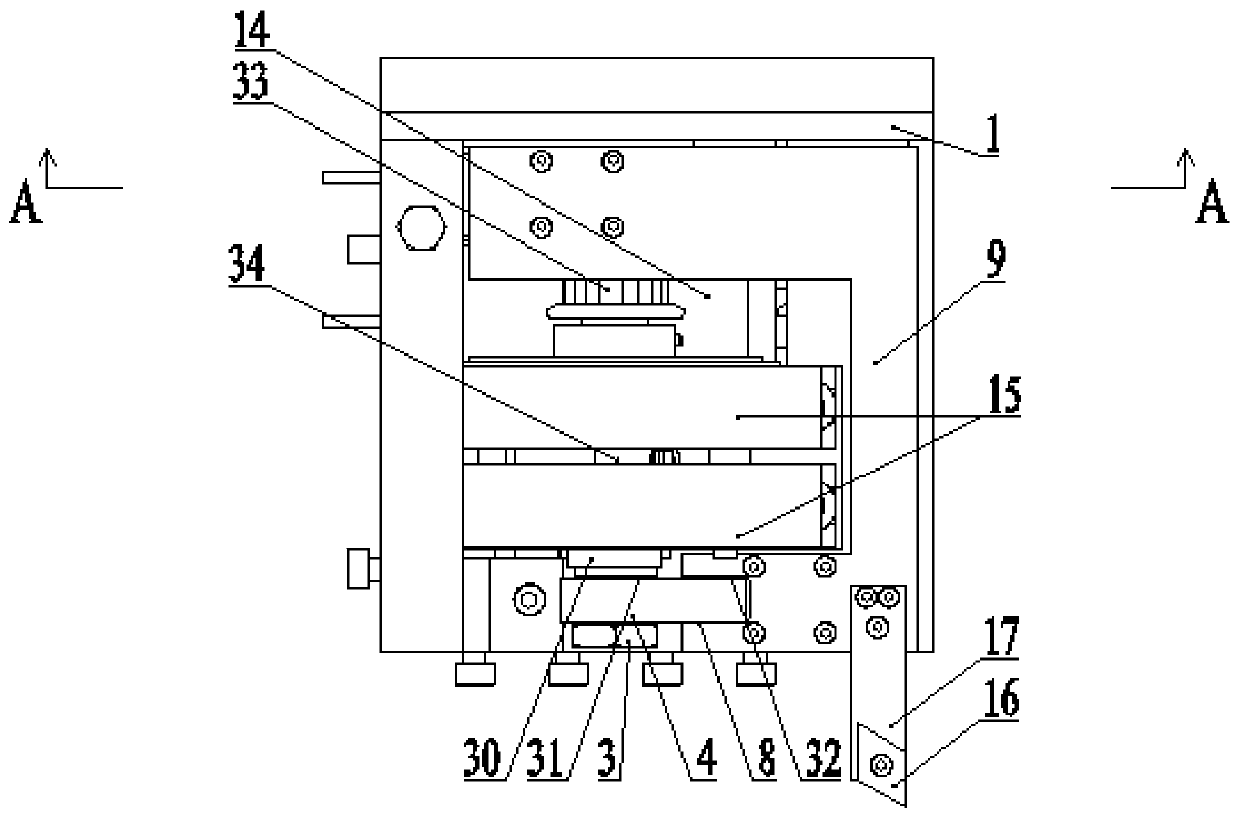

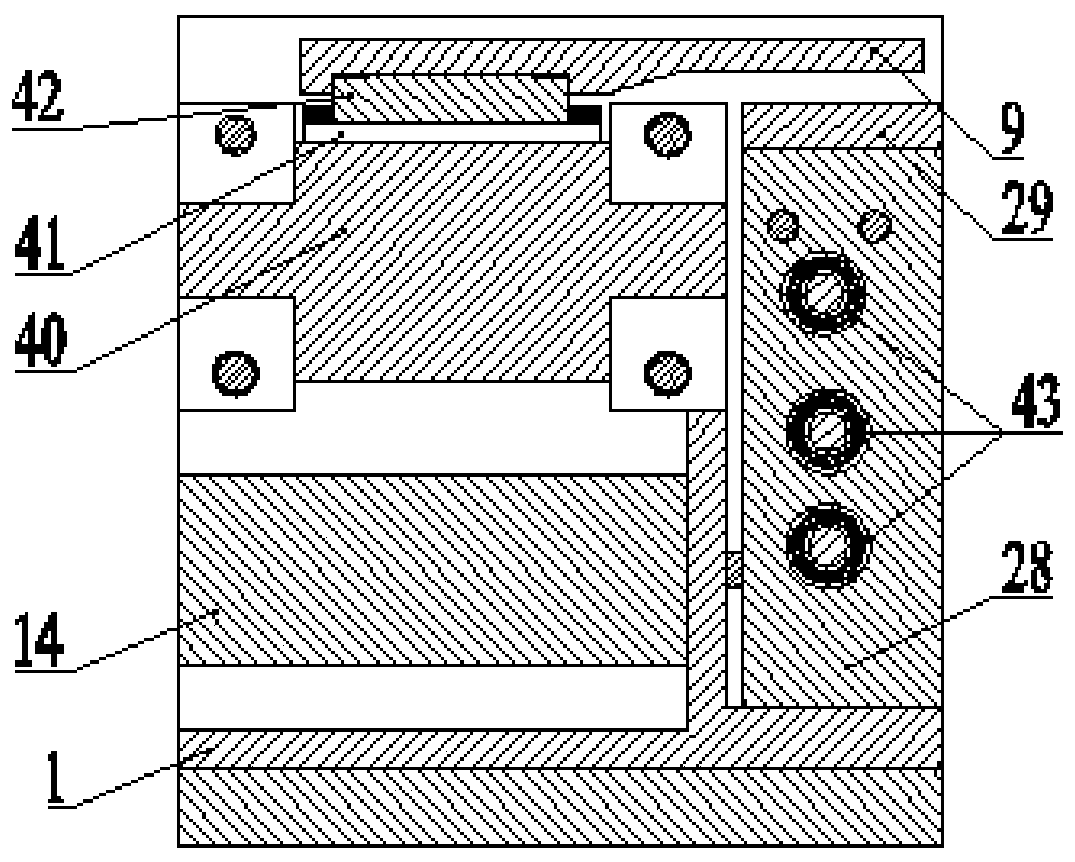

[0025] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-8 As shown, a low-frequency vibration cutting chip breaking device includes a housing, a vibration cutting device and a power unit.

[0026] The vibration cutting device includes an amplitude modulation module 34, a vibration transmission module and a power transmission module.

[0027] The amplitude modulation module 34 includes an eccentric sleeve A35, an eccentric sleeve B37, a torsion worm 39, a torsion worm fixing plate 36, a deep groove ball bearing A38, an anti-off disc 11, an angle indicating disc 12, an angle pointer 30, and a tapered roller Bearing 10, large self-lubricating bearing 31 and lock nut 3; the left section of the eccentric sleeve A35 is a connecting shaft on which a synchronous pulley B33 is installed, and the right section of the eccentric sleeve A35 has an eccentric Column and a sleeve sealed at the bottom of the left end, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com