Ultrasonic cutter handle

A tool holder and ultrasonic technology, applied in the field of milling processing, can solve the problem of not meeting the requirements of material processing, and achieve the effect of improving processing efficiency and processing quality, increasing excitation frequency and ensuring dynamic balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The ultrasonic knife holder proposed by the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims.

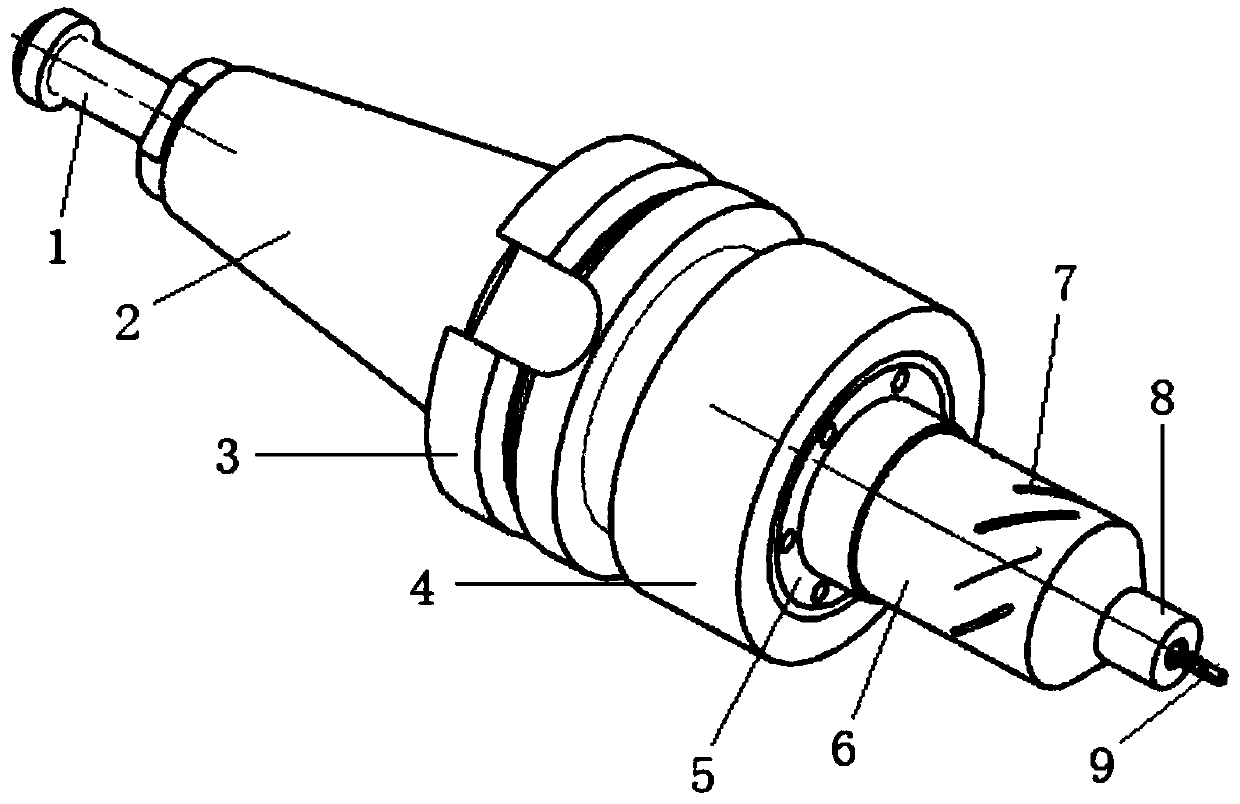

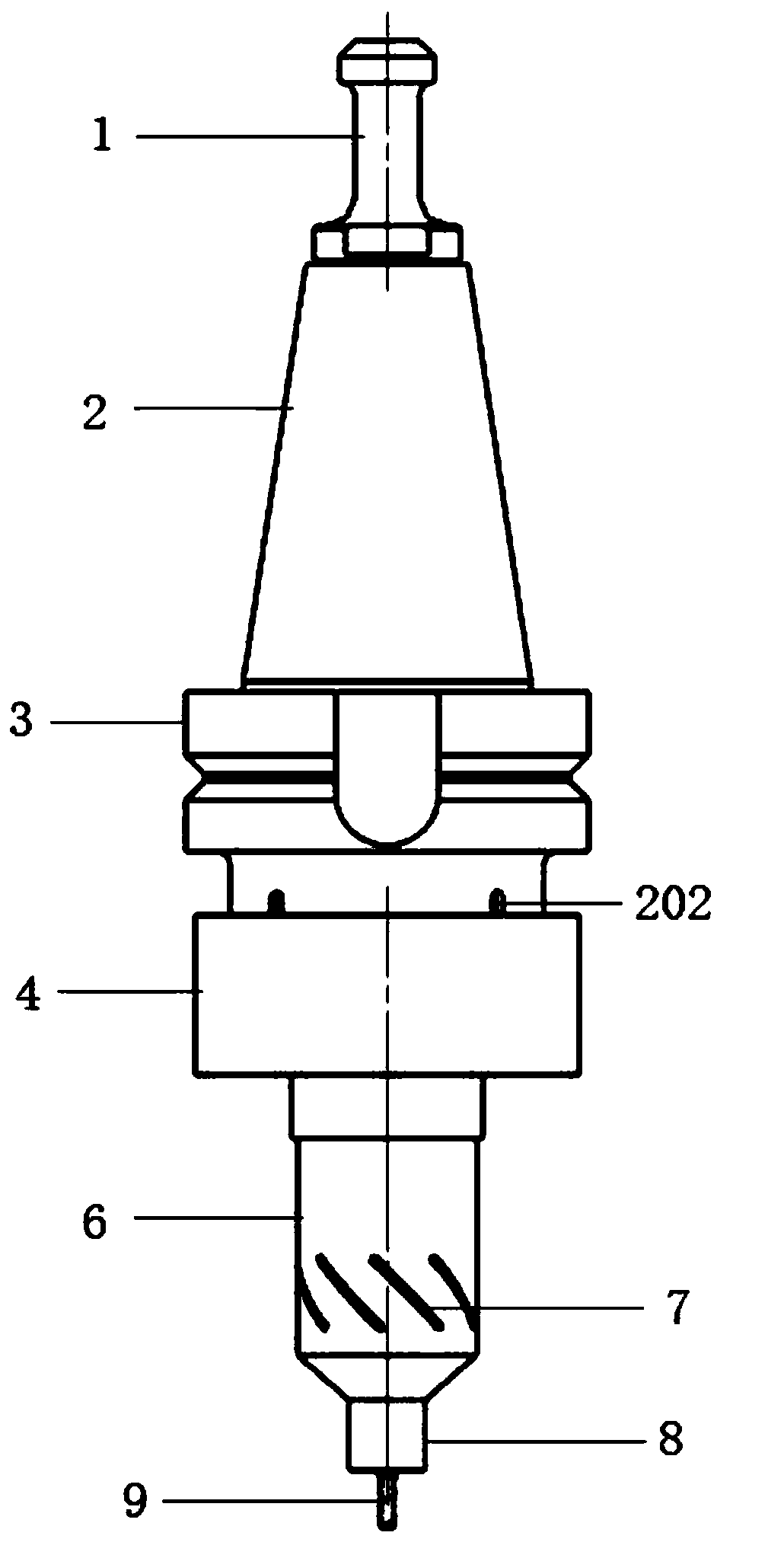

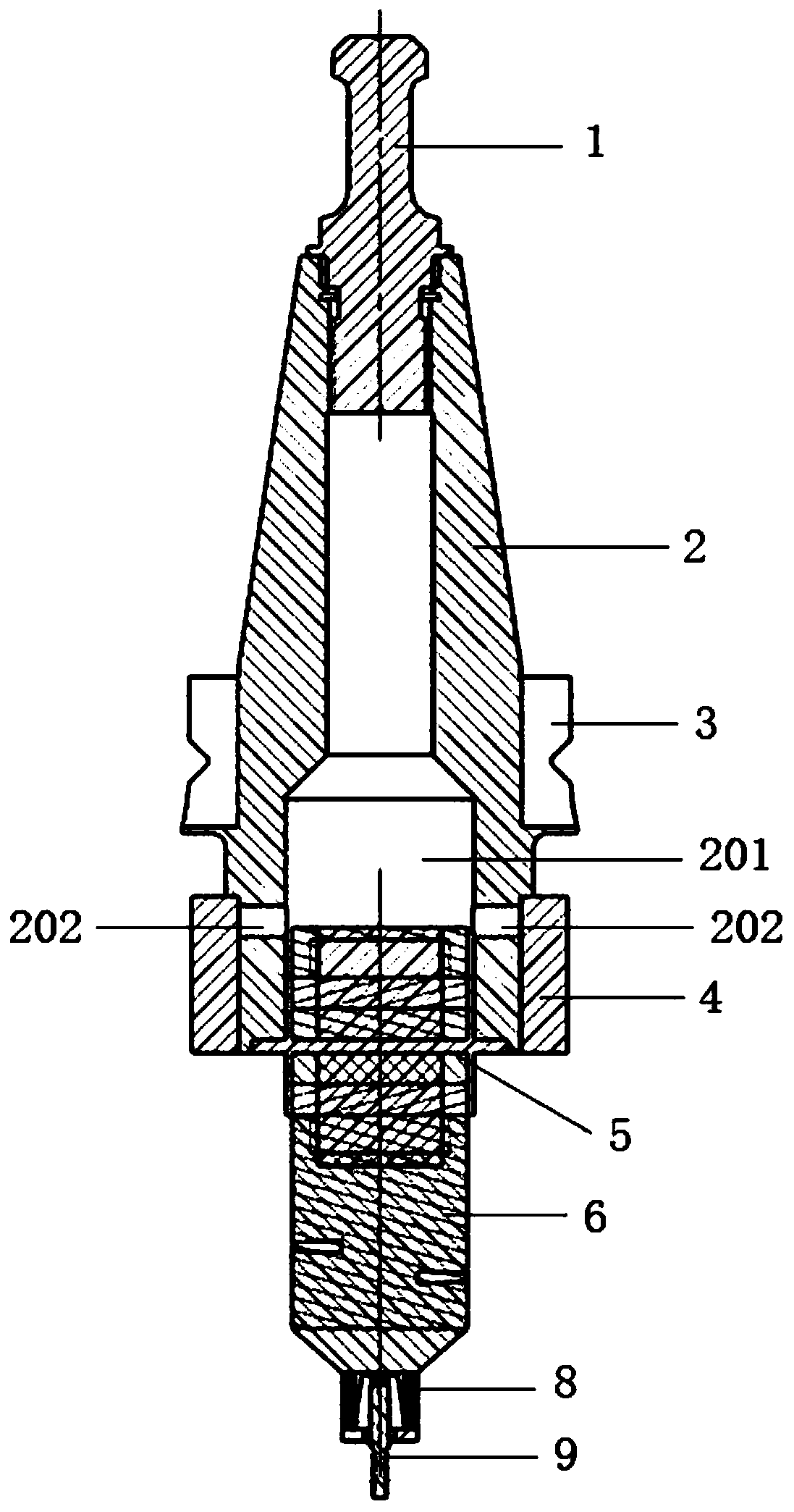

[0040] Such as figure 1 As shown, the ultrasonic knife handle provided by the present invention includes: pull stud 1; knife handle 2, the front end of knife handle 2 is detachably connected with pull stud 1, and the end of knife handle 2 is provided with cavity 201, and the opening of cavity 201 There is a depression with a diameter smaller than the outer diameter of the end of the handle 2; the flange 5 includes a first stud 501, a second stud 505, a first cylinder 502, a second cylinder 504 and a disc 503 ; The first stud 501 is fixed at the center of the upper surface of the disc 503, the first cylinder 502 is sleeved outside the first stud 501 and is fixedly connected with the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com