Treatment process of high-salt and high-organic-matter wastewater

A treatment process and organic matter technology, which is applied in the field of high-salt and high-organic waste water treatment process, can solve the problems of high salt content, difficult to effectively treat, direct biological method is difficult to achieve the treatment effect, etc., and achieve the effect of zero discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

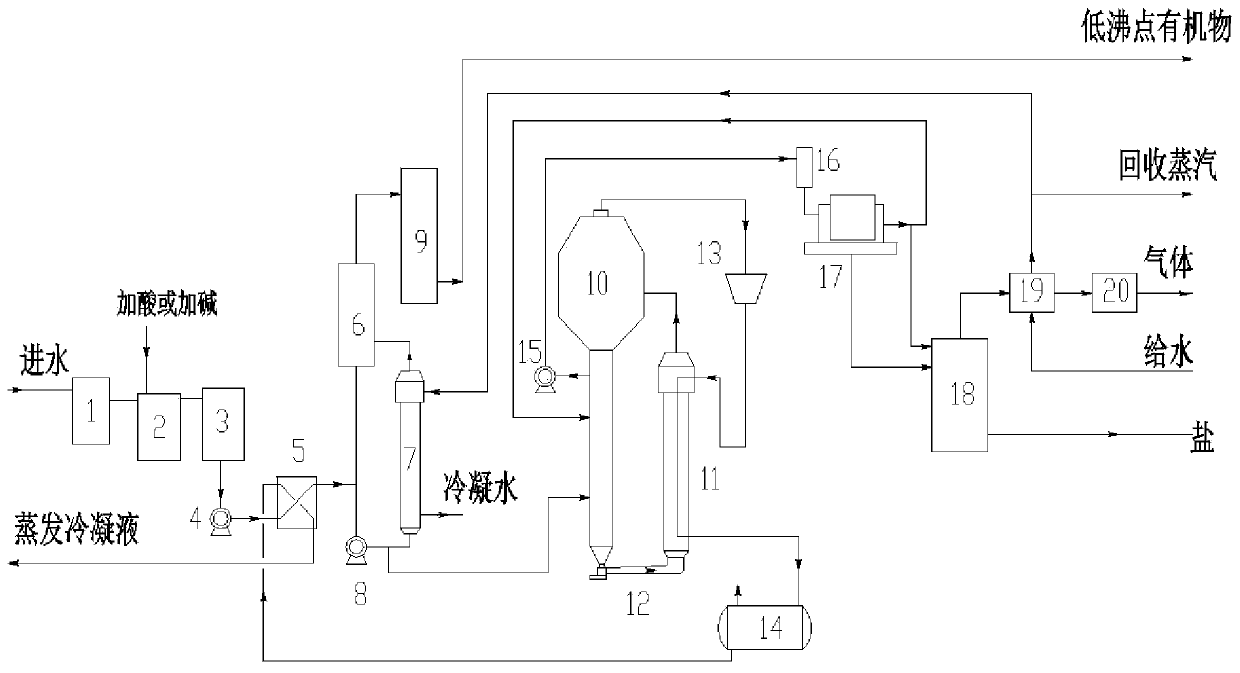

[0022] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

[0023] The high-salt and high-organic-matter wastewater treatment process: the high-salt and high-organic-matter wastewater sequentially passes through a sedimentation tank, a regulating tank, pre-evaporation, evaporation crystallization, and salt pyrolysis to obtain salt products that meet industrial requirements.

[0024] Such as figure 1 As shown, the high-salt and high-organic waste water first passes through the sedimentation tank 1, and is recovered or reused through static stratification, upper liquid separation and bottom sedimentation, and the intermediate main water phase enters the regulating tank 2.

[0025] Adjust the pH value of the water in the adjustment tank 2. When the water is acidic, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com