Environment-friendly asphalt warm mix regenerant and environment-friendly warm mix recycled asphalt pavement mixture

A technology of warm-mixing regenerated agent and recycled asphalt, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of adverse effects on the performance of asphalt mixtures, secondary aging of asphalt, etc., and achieve reduction of secondary aging, performance recovery, The effect of reducing the heating temperature requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The environmentally friendly asphalt warm mix rejuvenator is one of the important innovations of the present invention, and its formulation optimization process is as follows:

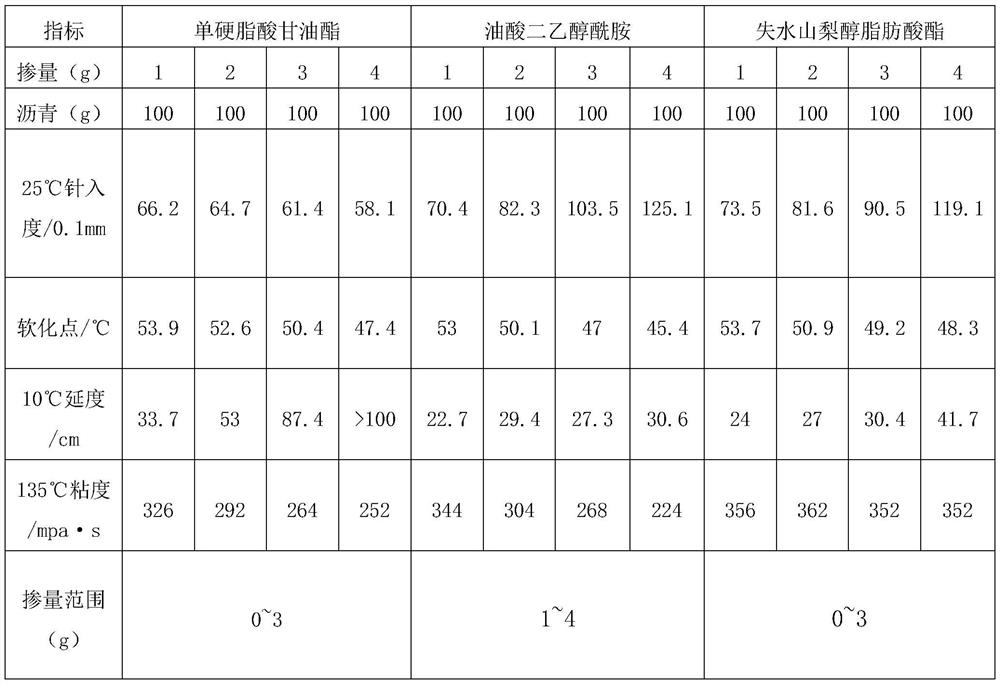

[0022] (1) Through a single factor experiment, study the change law of asphalt performance when the three surfactants in component A are added to 70# base asphalt alone, and determine the range of the three surfactants. The experimental results are shown in Table 1;

[0023] Table 1

[0024]

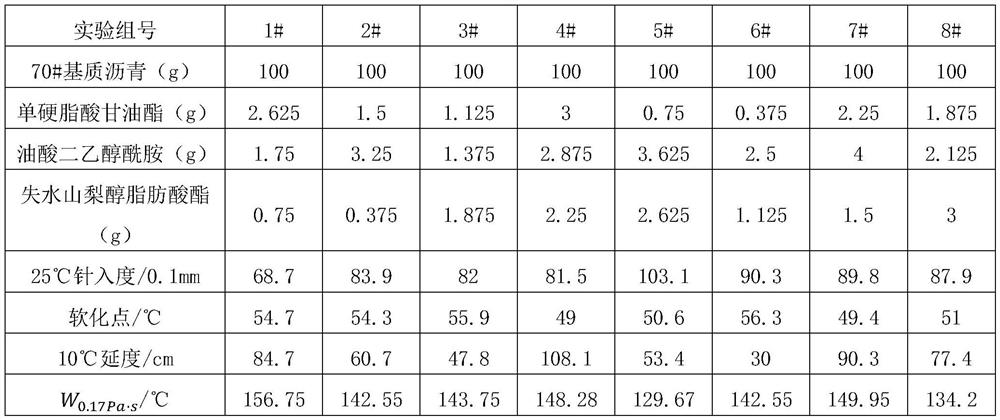

[0025] (2) According to the dosage range determined in step (1), design three factors and eight levels U 8 (8 3 ) homogeneous experiment, when testing three kinds of surfactants mixed simultaneously, the temperature of the asphalt (W 0.17Pa·s ), the experimental results are shown in Table 2;

[0026] Table 2

[0027]

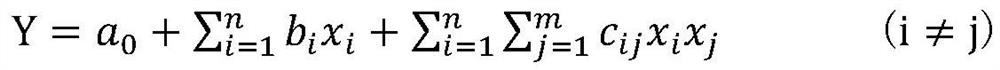

[0028] The "multi-factor and interaction item stepwise regression method" was used to fit the relationship between the performance index of 70# base asphalt and the content of surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com