High-efficiency polyester fabric dyeing method

A technology of polyester fabric and dyeing method, applied in the field of dyeing, can solve the problems of short cloth tape, unsatisfactory production efficiency, increased water and energy consumption, etc., achieve small batch differences, improve dyeing processing efficiency, and consume less energy, water and water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of efficient polyester fabric dyeing method,

[0047] Fabric to be dyed: width 1.5 meters, weight 80g / m 2 , each piece of fabric is connected end to end to form a first cloth tape with a length of 300 meters and a second cloth tape with a length of 270 meters;

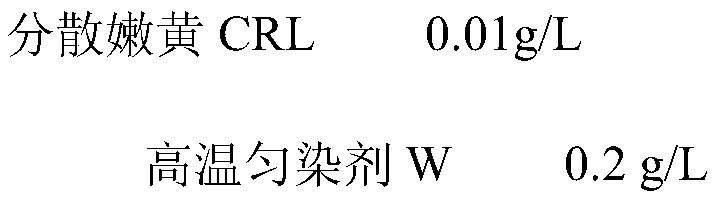

[0048] Dye formula:

[0049]

[0050]

[0051] Restorative Cleansing Solution Formula:

[0052] 50% caustic soda solution 3.0ml / L

[0053] Sodium Hydrochloride 2.5g / L

[0054] Nonylphenol polyoxyethylene ether-10 0.1g / L.

[0055] Specifically include the following steps:

[0056] Step 1: Calculate the water consumption according to the bath ratio of 1:10, and add all the calculated water to the overflow dyeing machine.

[0057] Step 2. Align and fix the head end of the first cloth tape and the head end of the second cloth tape, put them into the dye tank of the overflow dyeing machine, and turn on the cloth guide wheel and the main pump to feed the cloth. Fixing the first cloth tape and the s...

Embodiment 2

[0067] A kind of efficient polyester fabric dyeing method,

[0068] Fabric to be dyed: width 1.5 meters, weight 150g / m 2 , each piece of fabric is connected end to end to form a first cloth tape with a length of 270 meters and a second cloth tape with a length of 260 meters;

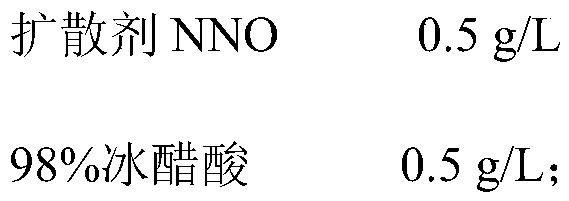

[0069] Dye formula:

[0070]

[0071] Restorative Cleansing Solution Formula:

[0072] 50% caustic soda solution 3.0ml / L

[0073] Sodium Hydrochloride 2.5g / L

[0074] Nonylphenol polyoxyethylene ether-10 0.3g / L.

[0075] Specifically include the following steps:

[0076] Step 1: Calculate the water consumption according to the bath ratio of 1:11, and add all the calculated water to the overflow dyeing machine.

[0077] Step 2. Align and fix the head end of the first cloth tape and the head end of the second cloth tape, put them into the dye tank of the overflow dyeing machine, and turn on the cloth guide wheel and the main pump to feed the cloth. Fixing the first cloth tape and the second cloth...

Embodiment 3

[0087] A kind of efficient polyester fabric dyeing method,

[0088] Fabric to be dyed: width 1.5 meters, weight 250g / m 2 , each piece of fabric is connected end to end to form a first cloth tape with a length of 280 meters and a second cloth tape with a length of 260 meters;

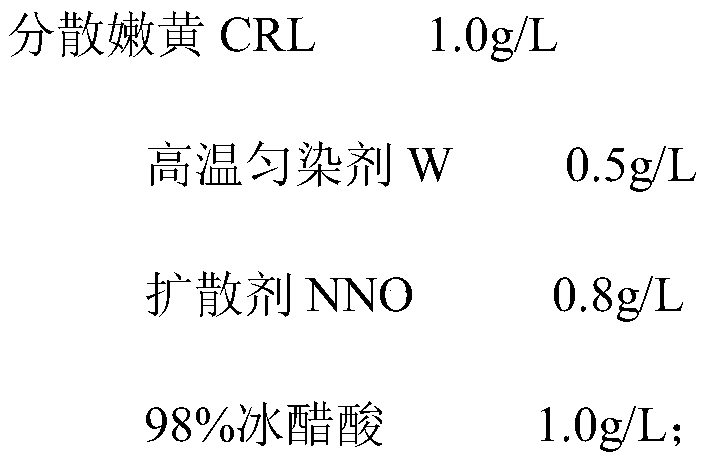

[0089] Dye formula:

[0090]

[0091] Restorative Cleansing Solution Formula:

[0092] 50% caustic soda solution 3.0ml / L

[0093] Sodium Hydrochloride 2.5g / L

[0094] Nonylphenol polyoxyethylene ether-10 0.5g / L.

[0095] Specifically include the following steps:

[0096] Step 1: Calculate the water consumption according to the bath ratio of 1:12, and add all the calculated water to the overflow dyeing machine.

[0097] Step 2. Align and fix the head end of the first cloth tape and the head end of the second cloth tape, put them into the dye tank of the overflow dyeing machine, and turn on the cloth guide wheel and the main pump to feed the cloth. Fixing the first cloth tape and the second cloth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com