A Corrosion Test Device Capable of Alternating Water Depth

A technology of alternating water depth and corrosion test, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as unusable performance tests, and achieve easy assembly and disassembly, convenient use, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below.

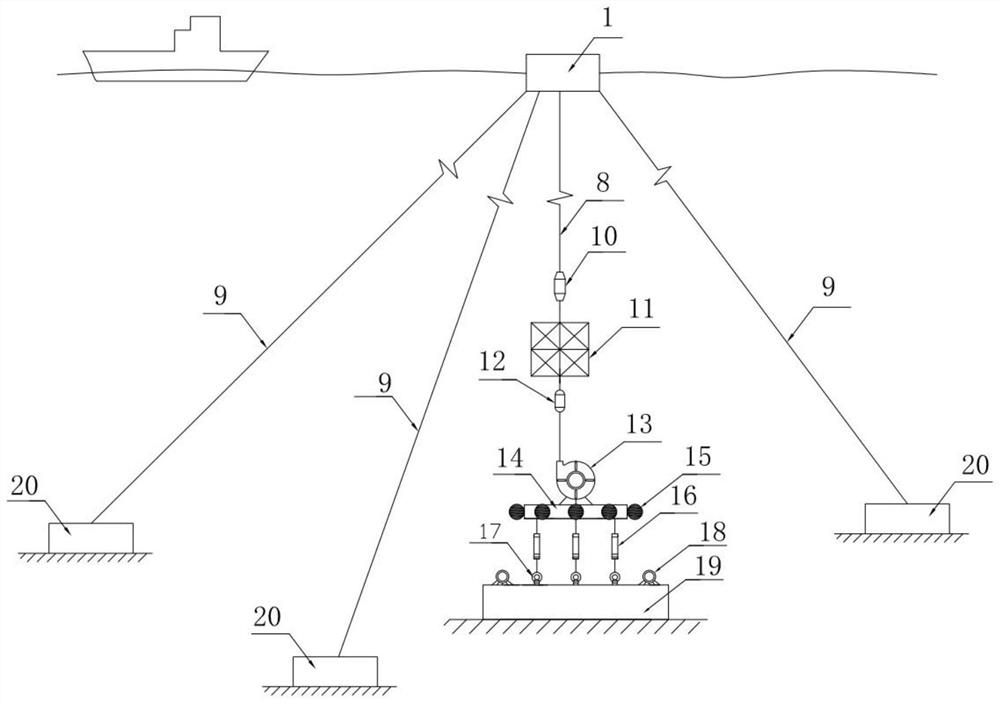

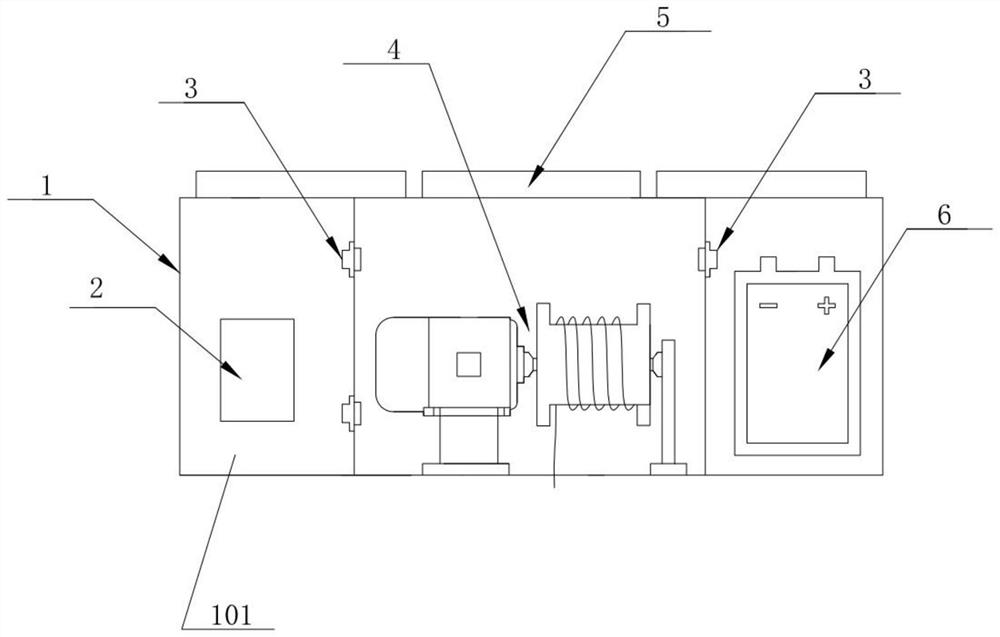

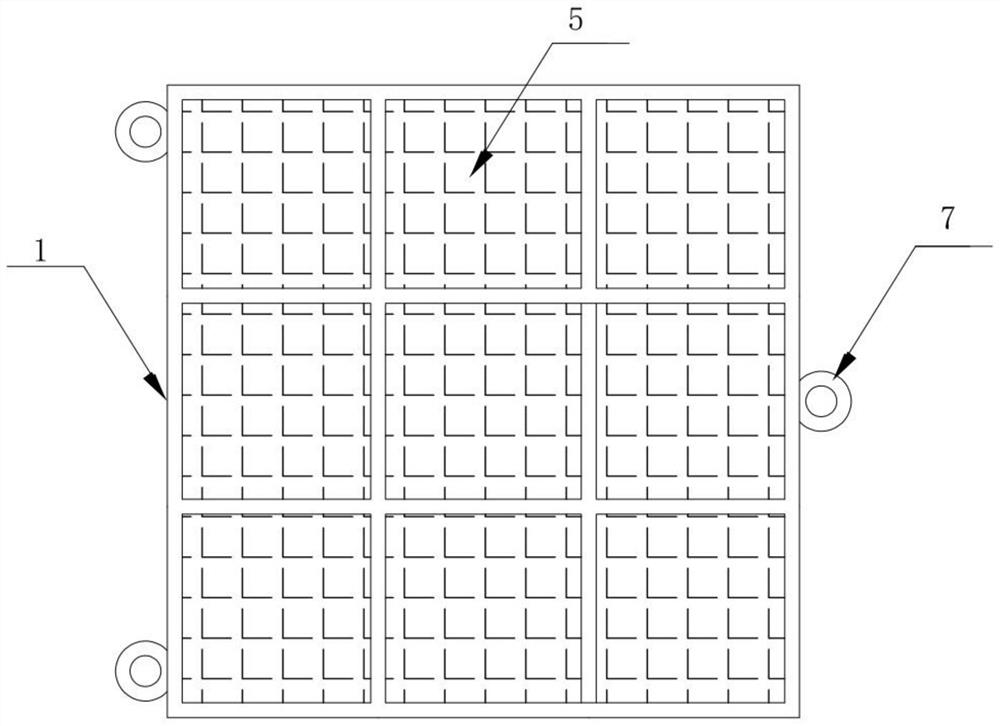

[0024] Such as Figure 1 to Figure 3 As shown, a corrosion test device that can realize alternating water depth of sample injection includes a buoyancy tank 1 , a winch system 4 , a test frame 11 , an automatic wire reel 13 , a base 14 , an acoustic release device 16 and a ballast block 19 . The pontoon 1 is made of titanium alloy material. A plurality of fixing parts are set outside the buoyant tank 1. In the present embodiment, the fixing parts adopt a fixing ring 7 made of titanium alloy, and each fixing ring 7 is connected with one end of the mooring cable 9 for fixing the position of the buoyant tank 1. The other end of each mooring cable 9 is connected with the mooring concrete block 20 .

[0025] The interior of the buoyancy tank 1 is composed of several sealed cavities 101 and a single unsealed cavity. The winch system 4 is located in the unsealed cavity. Each sealed cavity 101 is respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com