Experiment device and experiment method for high-temperature high-flow-velocity gas flow heat transfer

A gas flow and heat experiment technology, applied in the field of energy and power, can solve the problems of few experimental devices, complex structure, high energy density, etc., and achieve the effects of ensuring safety, facilitating experimental observation, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

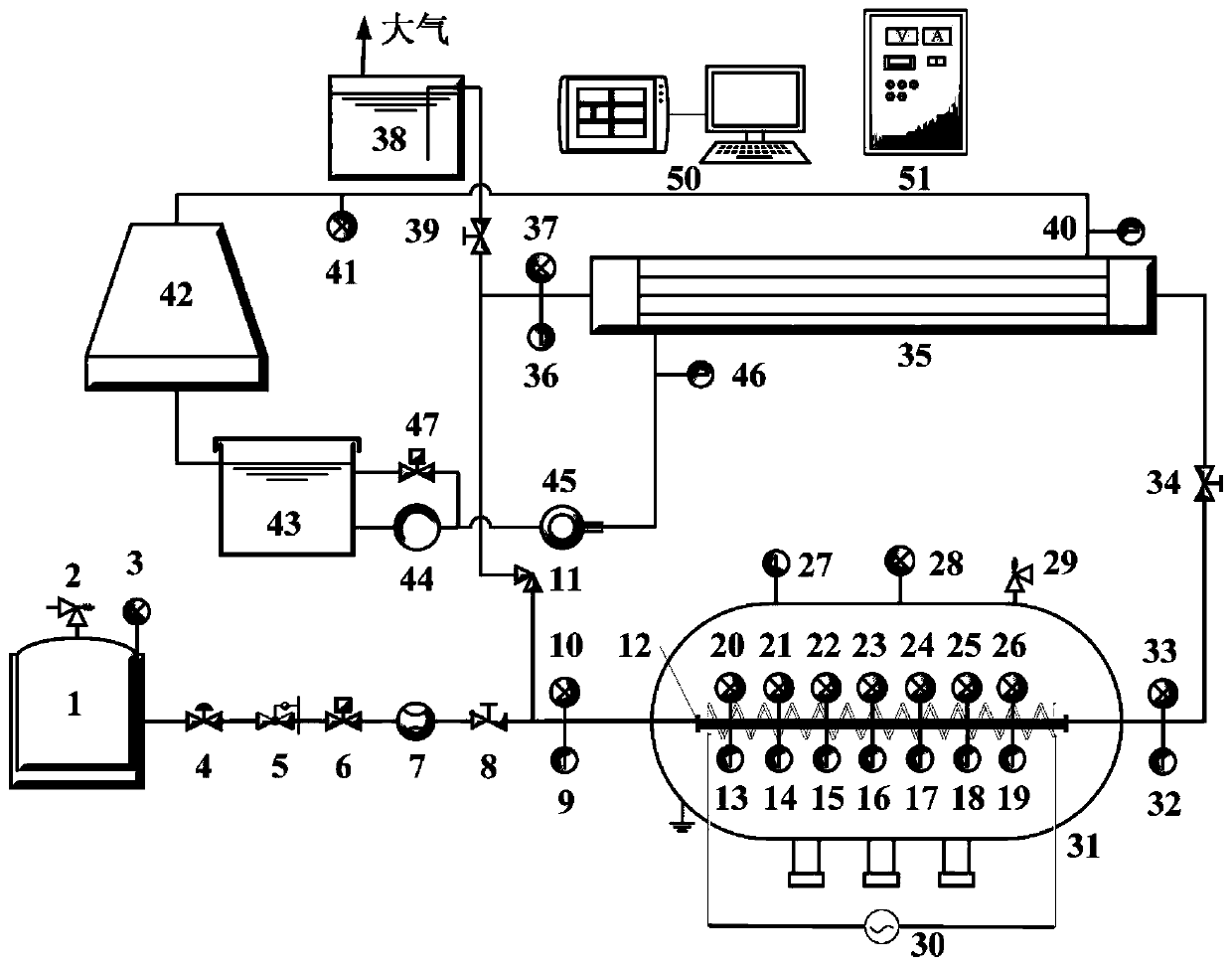

[0035] In order to better illustrate the present invention, the working principle of the present invention will now be described in detail in conjunction with the accompanying drawings.

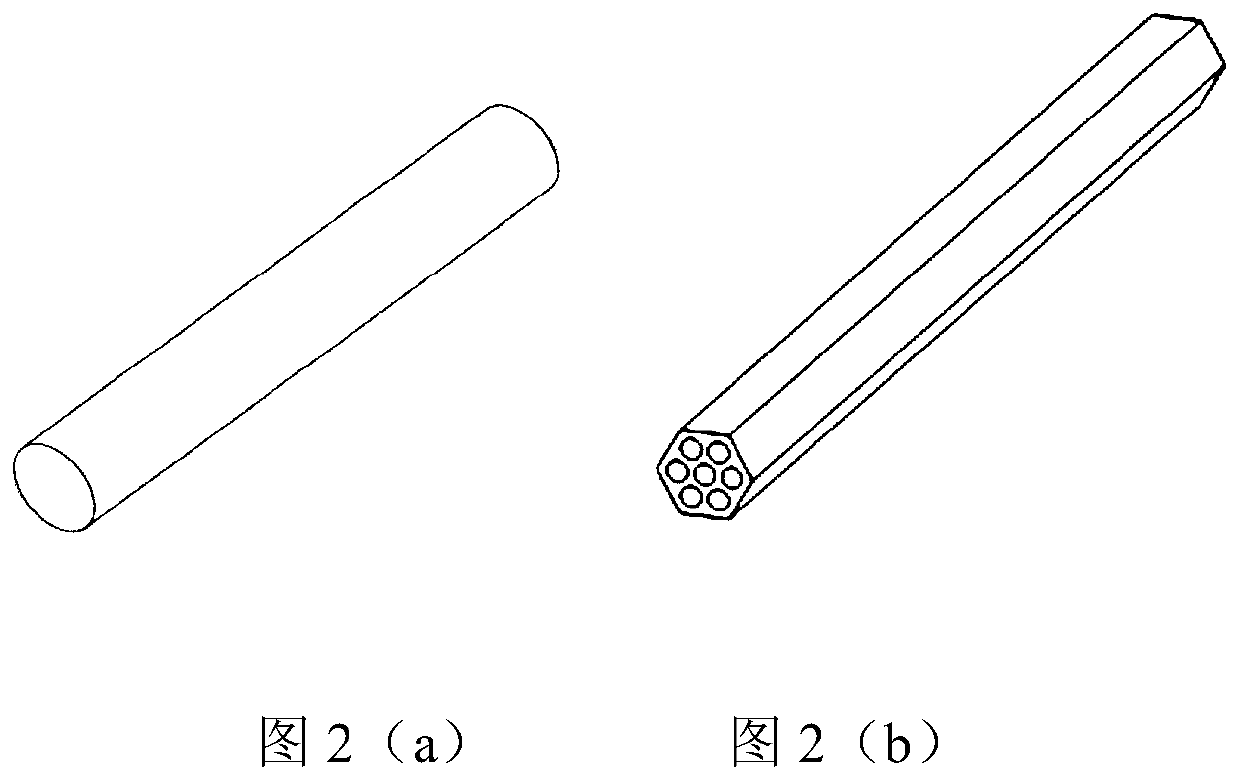

[0036] The experimental device of the present invention can conduct research on the heat transfer characteristics of high-temperature, high-pressure, and high-velocity gas flows. The coolant can use various gas working fluids such as hydrogen, helium, argon, nitrogen, and carbon dioxide. The heating section can also choose stainless steel round tubes, Tungsten alloy round tube single-channel or multi-channel structure. By changing the gas open circuit working medium of the experimental device, the geometric structure of the heating section, the pressure, the flow rate and other thermal parameters, the gas flow heat transfer characteristics are studied, and other related gas cooling systems such as high-temperature gas-cooled reactors and nuclear thermal propulsion reactors that use gas cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com