Oxidation-state reforming catalyst and preparation method thereof

A technology for reforming catalysts and oxidation states, which is applied in physical/chemical process catalysts, chemical instruments and methods, catalytic reforming of naphtha, etc., and can solve problems such as easy generation of coke deposits and large particle size of platinum clusters. Achieve the effects of not easy to aggregate, small particle size, and enhanced interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of an oxidation state reforming catalyst, the preparation method comprising the following steps:

[0035] Step 1, preparing a tin-containing alumina carrier;

[0036] Step 2, impregnating the carrier in step 1, the impregnation temperature is 10-50°C, the impregnation solution includes platinum-containing compounds, rare earth compounds, competing adsorbents and nitrogen-containing compounds; and

[0037] Step 3, drying and activating the carrier impregnated in step 2 to obtain a reforming catalyst;

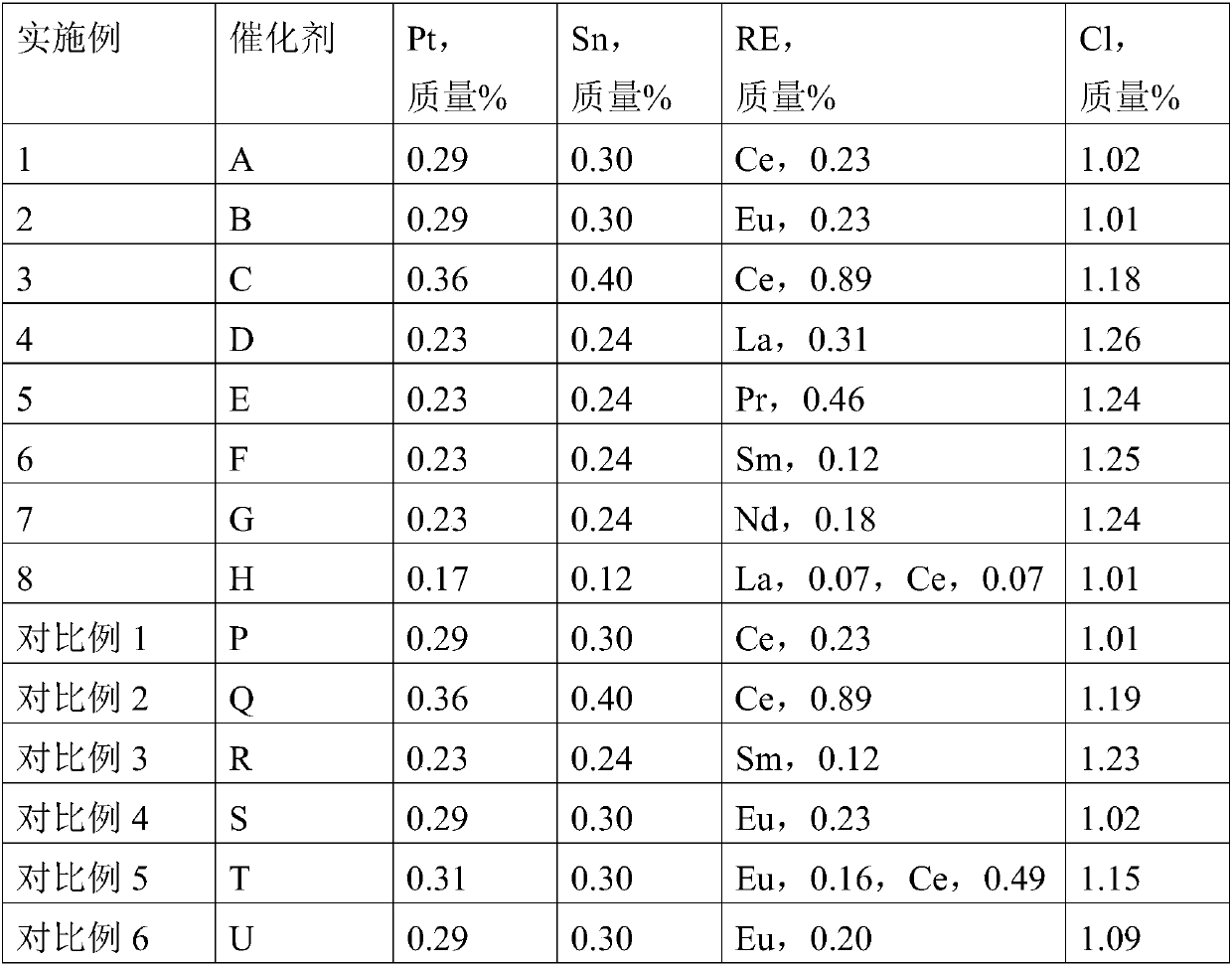

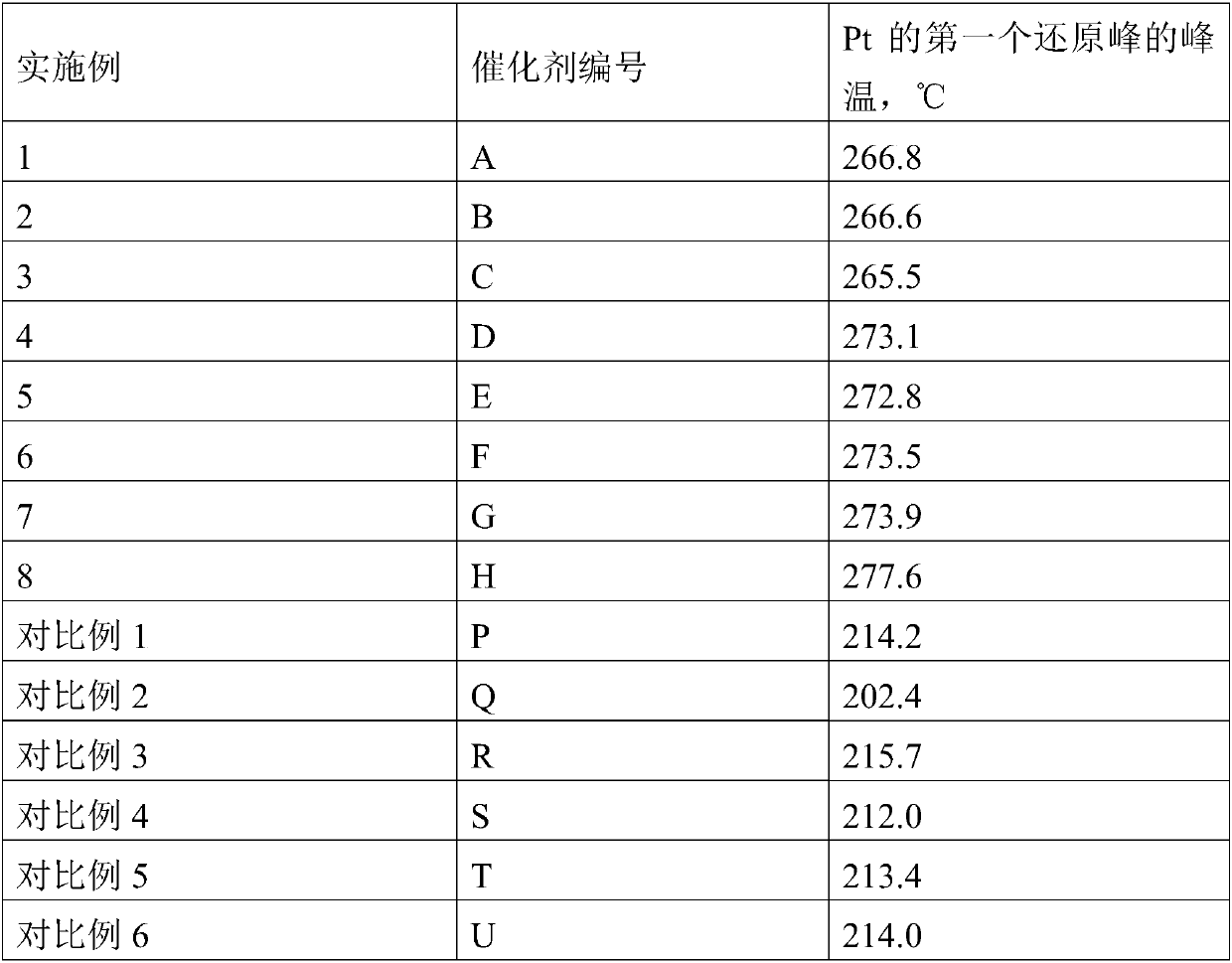

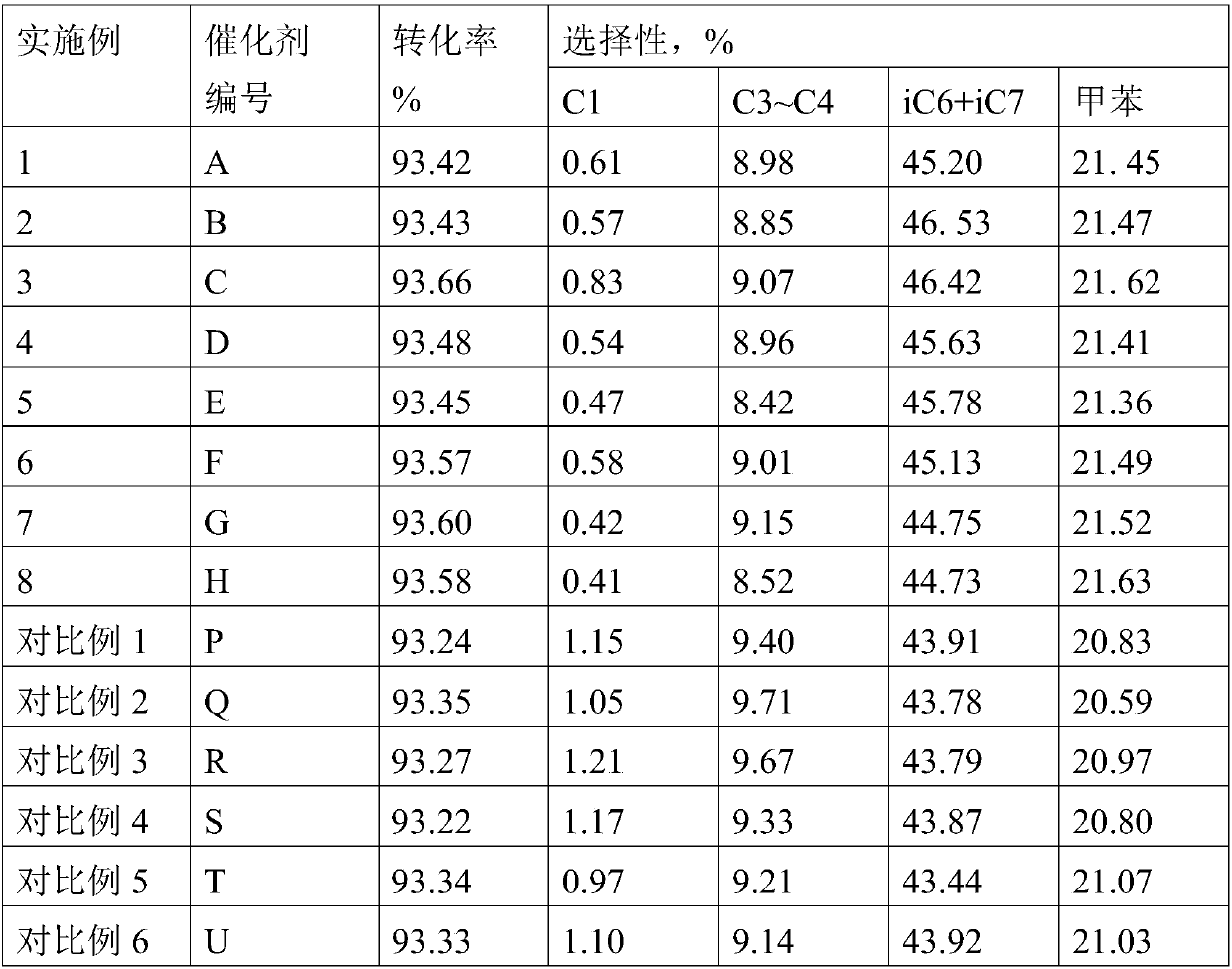

[0038] Wherein, the reforming catalyst includes 0.1-0.4 mass % of platinum, 0.1-0.6 mass % of tin, 0.05-1 mass % of rare earth and 0.3-3.0 mass % of chlorine based on the total mass of the alumina carrier on a dry basis.

[0039]In the present invention, the steps of preparing the tin-containing alumina carrier are not particularly limited, as long as the requirements of the present invention can be met. The shape of the alumin...

Embodiment 1

[0053] Take 100 grams of pseudo-boehmite (manufactured by Sasol) and an appropriate amount of deionized water with a liquid / solid mass ratio of 2, and stir at room temperature for 0.5 hour slurrying. Then add 3 milliliters of nitric acid, and a predetermined amount of stannous chloride hydrochloric acid solution, so that the Sn content in the solution is 0.30% by mass relative to the alumina on a dry basis, and acidify for 2 hours. Then drop the ball into the oily ammonia column, solidify the wet ball in ammonia water for 1 hour, then filter, wash with deionized water three times, dry at 60°C for 6 hours, dry at 120°C for 2 hours, and bake at 650°C for 4 hours in a flowing air atmosphere. Hours, the Sn-containing alumina pellet carrier was obtained.

[0054] Prepare an impregnating solution containing chloroplatinic acid, cerium nitrate, hydrochloric acid and urea according to a predetermined amount, and the contents of platinum, cerium, HCl and urea in the impregnating soluti...

Embodiment 2

[0056] Catalyst B is prepared according to the method of Example 1, except that the rare earth compound is europium nitrate in the impregnation solution, and the specific steps are as follows:

[0057] Take 100 grams of pseudo-boehmite (manufactured by Sasol) and an appropriate amount of deionized water with a liquid / solid mass ratio of 2, and stir at room temperature for 0.5 hour slurrying. Then add 3 milliliters of nitric acid, and a predetermined amount of stannous chloride hydrochloric acid solution, so that the Sn content in the solution is 0.30% by mass relative to the alumina on a dry basis, and acidify for 2 hours. Then drop the ball into the oily ammonia column, solidify the wet ball in ammonia water for 1 hour, then filter, wash with deionized water three times, dry at 60°C for 6 hours, dry at 120°C for 2 hours, and bake at 650°C for 4 hours in a flowing air atmosphere. Hours, the Sn-containing alumina pellet carrier was obtained.

[0058] Prepare an impregnating so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com