Fast-frequency pulse TIG welding system

A welding system and pulse technology, applied in the field of fast-frequency pulse TIG welding system, can solve the problem that the fast-frequency pulse TIG welding technology has not been widely used, the response speed is restricted, the reliability of fast-frequency pulse TIG welding, and the high-frequency arc control effect is poor. and other problems, to achieve good dynamic response speed, good driving effect, and the effect of strengthening the arc control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

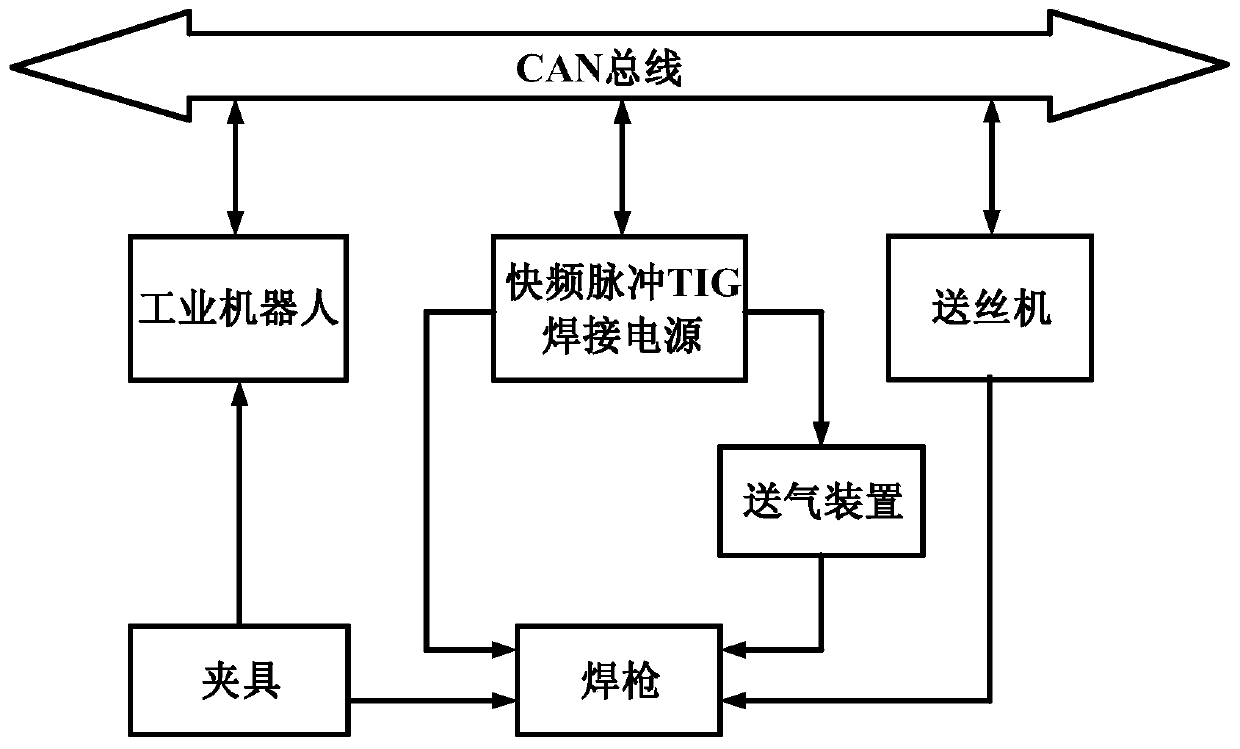

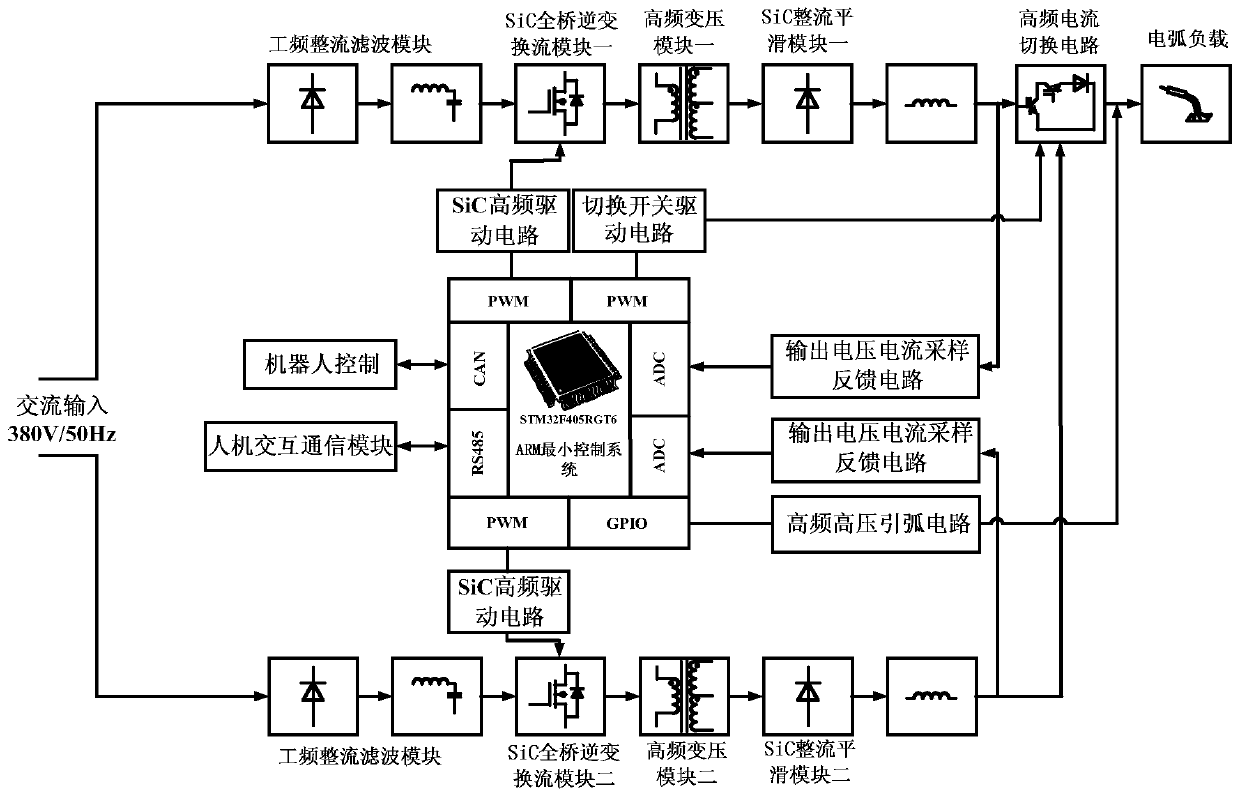

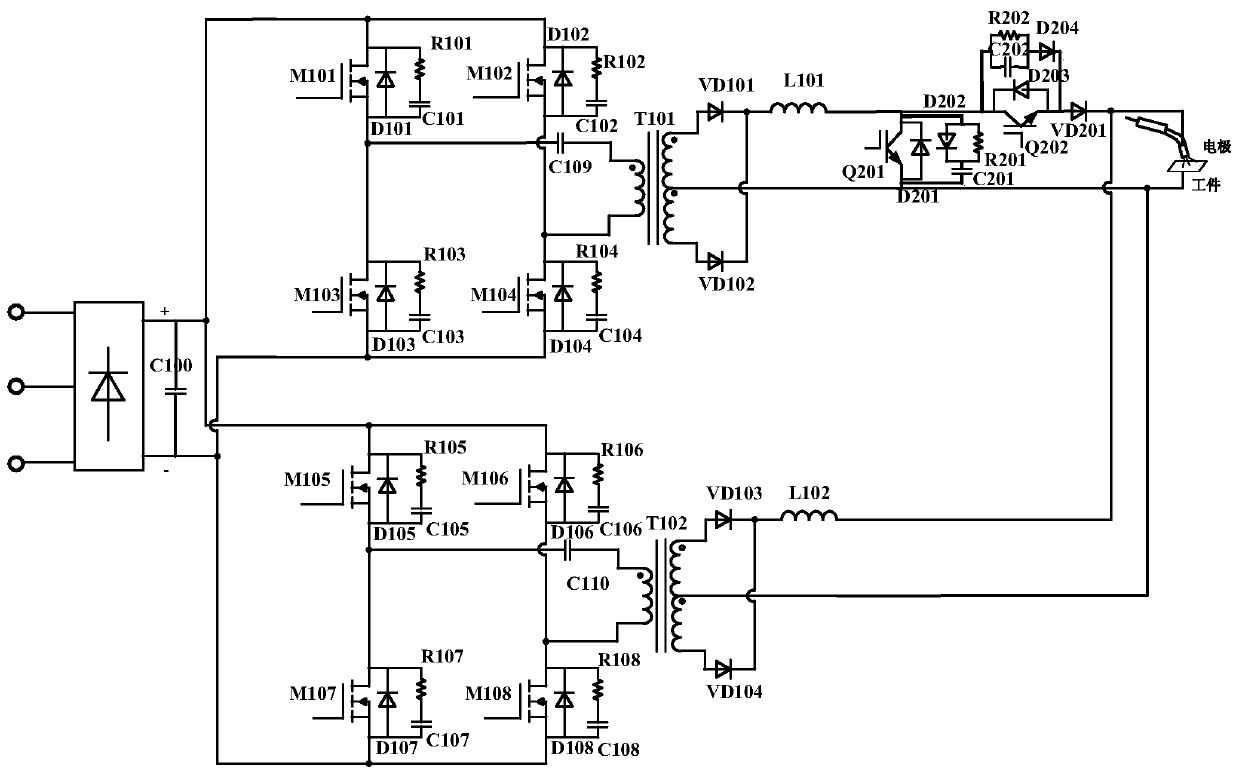

[0043] In this embodiment, a fast-frequency pulse TIG welding system has a structure such as Figure 1 to Figure 7 As shown, it includes a fast-frequency pulse TIG welding power supply, and also includes an industrial robot, a wire feeder, a welding torch, an air supply device and a fixture; the industrial robot and the wire feeder are connected to the ARM minimum control system; the fixture is connected to the industrial robot and the welding torch respectively; The fast-frequency pulse TIG welding power supply is also connected with the gas supply device; the welding torch is also connected with the gas supply device and the wire feeder respectively.

[0044] The industrial robot is used as an actuator to hold the welding torch and perform welding operations according to a predetermined path. The wire feeder is used to realize the precise stepless adjustment of the welding wire feeding speed and the diversification of the wire feeding methods, so as to ensure that the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com