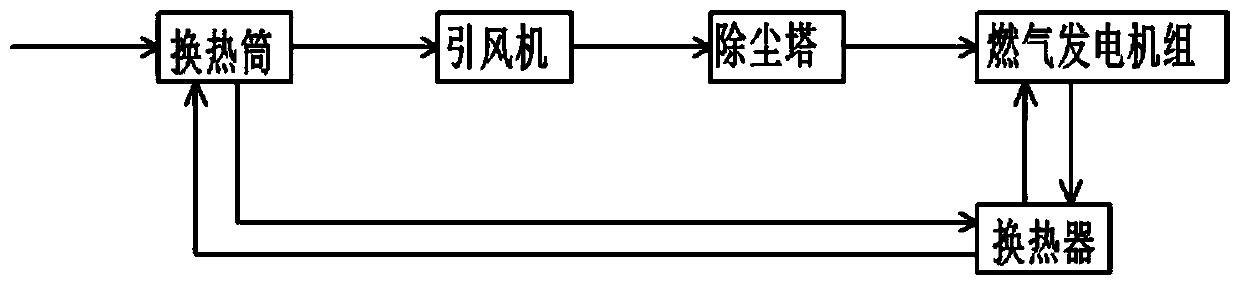

Carbon black tail gas internal combustion engine power generation method

An internal combustion engine, carbon black technology, applied in the direction of internal combustion piston engine, separation method, combustion engine, etc., can solve the problems of energy waste, environmental pollution, uneconomical, etc., and achieve the effect of improving economy, reducing environmental pollution and increasing enterprise cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

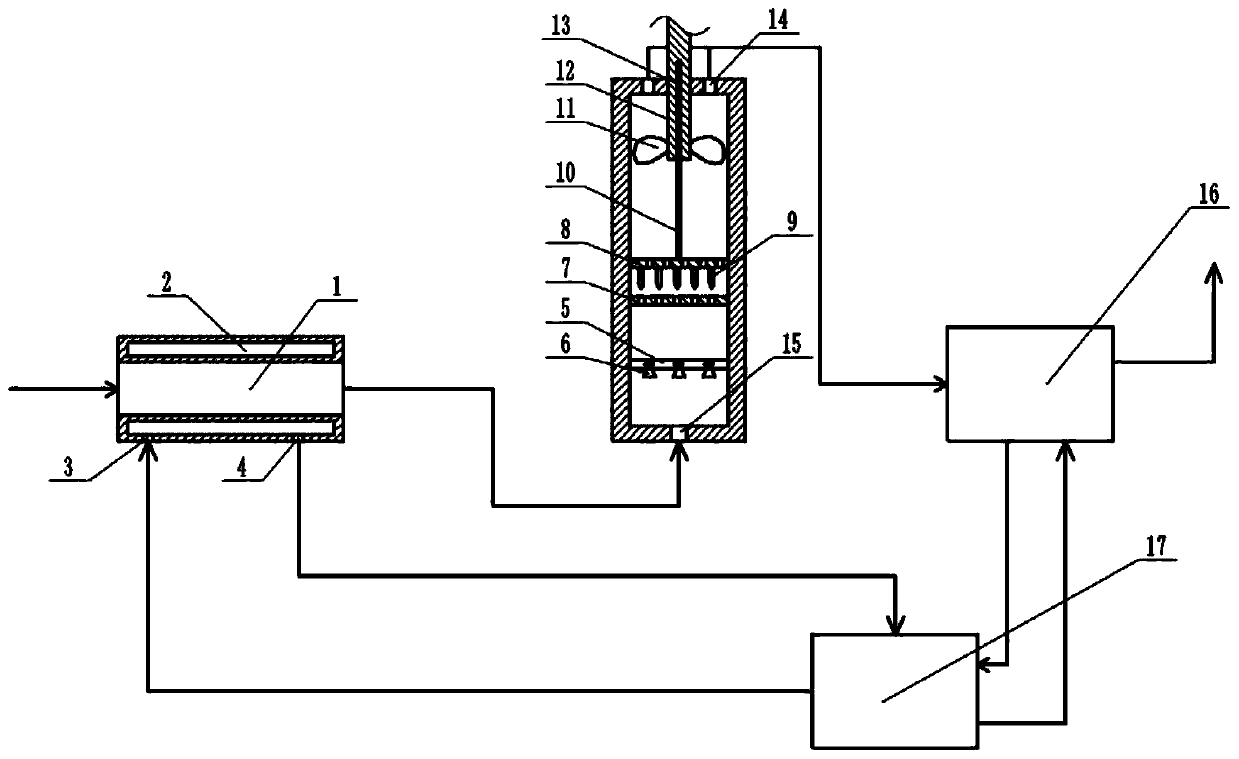

Examples

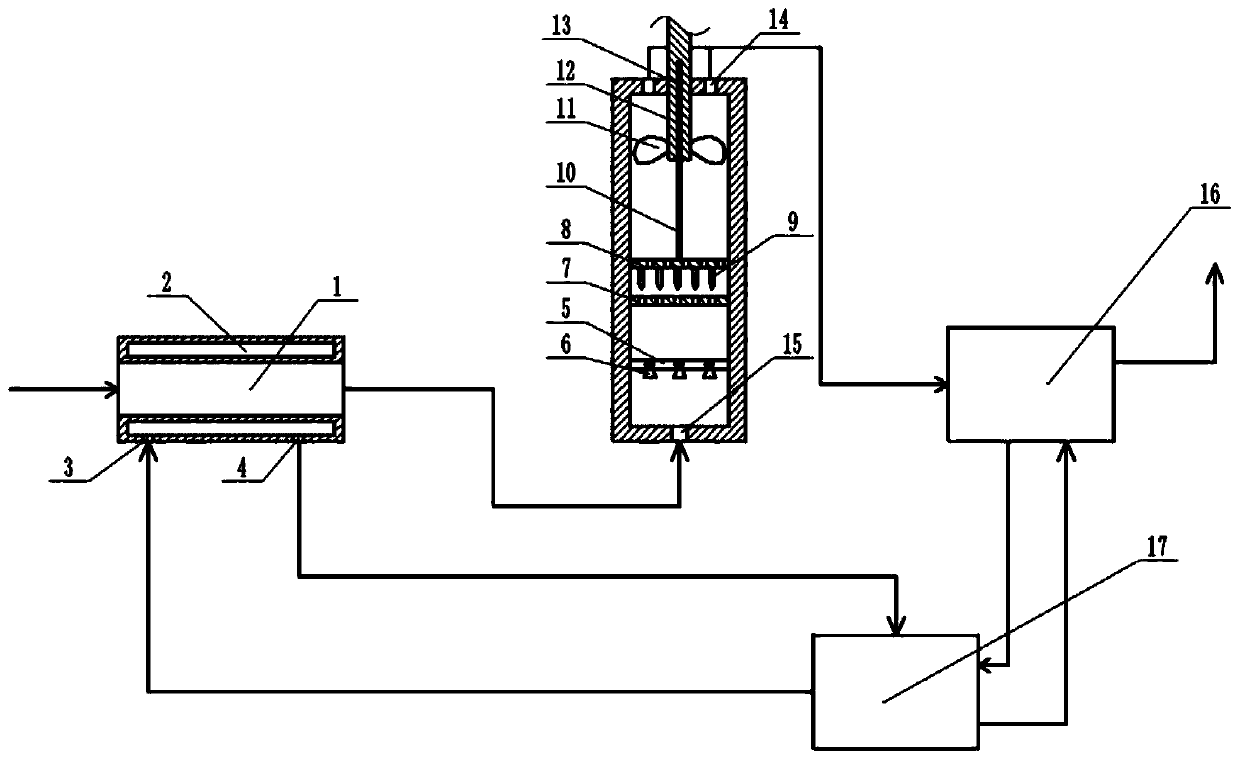

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is only that the setting of the dedusting tower is different. combine image 3 As shown, the top of the dedusting tower is provided with a negative pressure fan, and the negative pressure fan includes a rotating shaft 12 connected to the top of the dedusting tower and fan blades 11 evenly distributed on the rotating shaft 12, and a motor for driving the rotating shaft 12 is arranged outside the dedusting tower. The motor output shaft and the rotating shaft 12 are fixed. In the dust removal tower, a dust removal cloth bag 18 is fixed below the negative pressure fan. The bottom of the dust removal tower is provided with an exhaust gas inlet 15, and the top of the dust removal tower is provided with an exhaust gas outlet 14. The upper end of the dust removal bag 18 is fixed with a turntable 19, which is rotatably connected in the dust removal tower, and a connecting rod 20 is fixed between the upper end of the turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com