An electric pulse device and method for locally controlling the phase distribution of mold slag in the slag tunnel of a continuous casting mold

A continuous casting mold and mold flux technology is applied in the field of electric pulse devices for locally regulating the phase distribution of mold flux in the slag channel of the continuous casting mold, and achieves the effects of simple equipment, improved casting quality and high adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

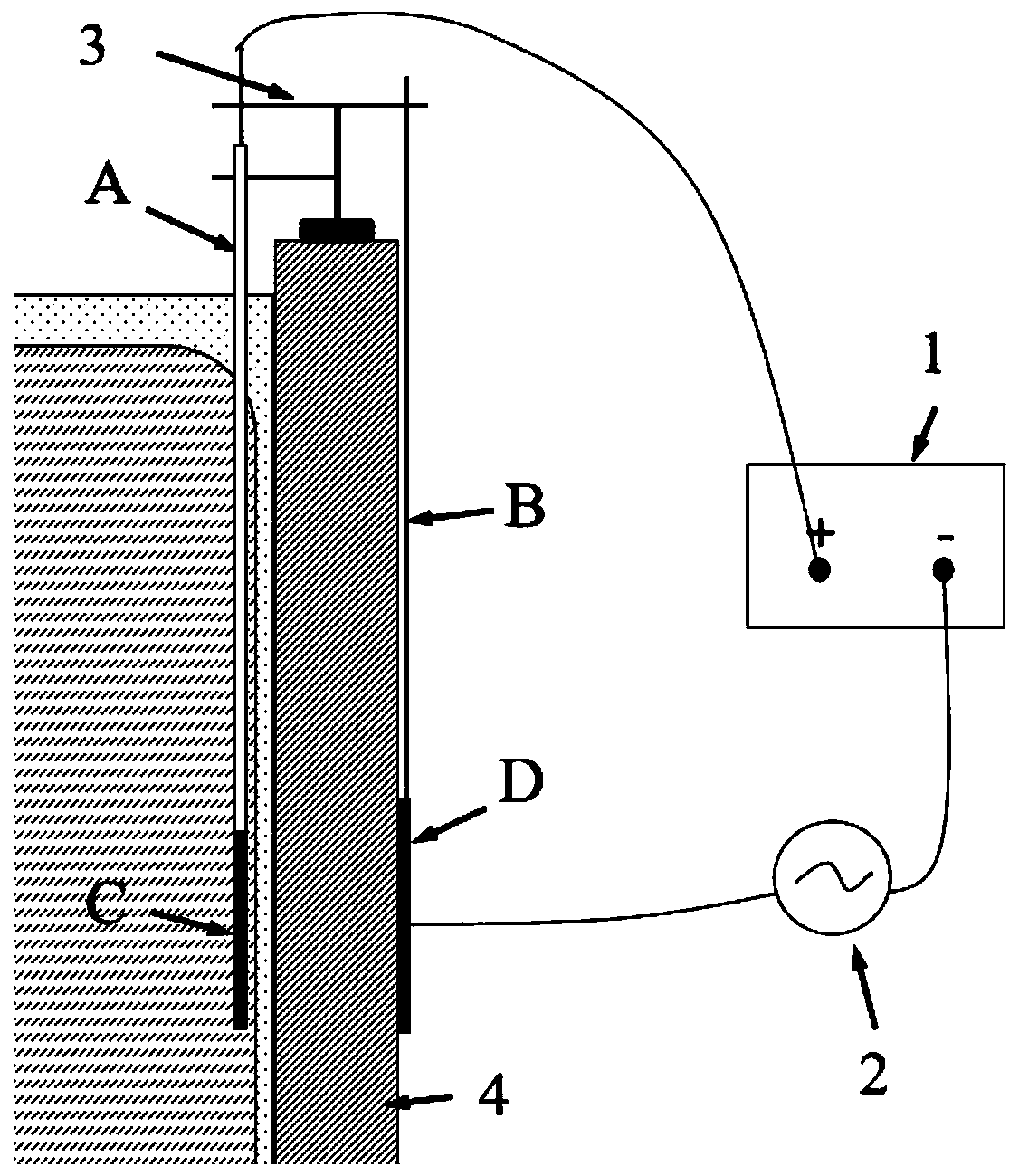

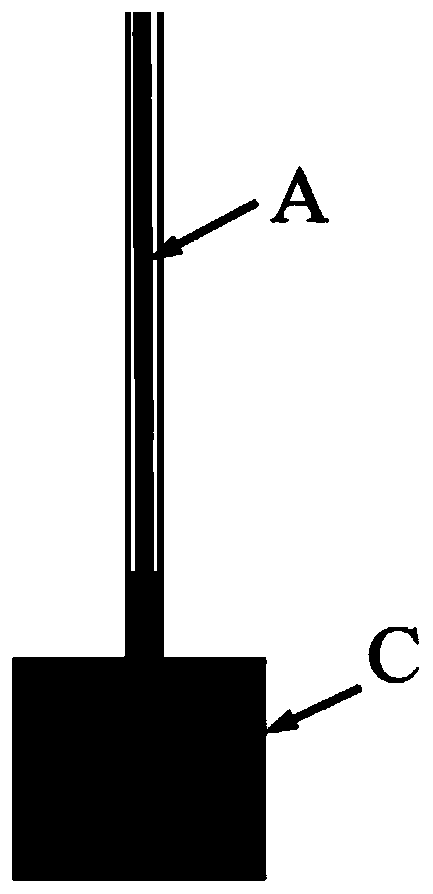

[0059] use figure 1 The electric pulse device for local control of the mold slag phase distribution in the slag channel of the continuous casting mold is shown to control the local area of excessive heat transfer in the continuous casting of 304 stainless steel. The peak current of the electric pulse is 30A, the output voltage is 24V, and the frequency is . 60Hz, the duty cycle is 0.6, the power-on time is 6min, and the electrode is 11mm away from the inner wall of the crystallizer.

[0060] After observation and sampling inspection, the cracks of the slab in this part are significantly reduced, the average thickness of the slag film is 2.7mm, the distribution is uniform, the crystallization rate is 83%, the grain size becomes larger, and the heat flow in this part is reduced by 95KW / m 2 .

Embodiment 2

[0062] use figure 1 The electrical pulse device for local control of mold slag phase distribution in the slag channel of the continuous casting mold is shown to control the local area of excessive heat transfer in IF steel continuous casting. The peak current of the electric pulse is 120A, the output voltage is 20V, and the frequency is 45Hz, the duty cycle is 0.3, the power-on time is 5min, and the electrode is 8mm away from the inner wall of the crystallizer.

[0063] After observation and sampling inspection, the cracks of the slab in this part are significantly reduced, the average thickness of the slag film is 3.7mm, the distribution is uniform, the crystallization rate is 86%, the grain size becomes larger, and the heat flow in this part decreases by 138KW / m 2 .

Embodiment 3

[0065] use figure 1 The electrical pulse device for locally regulating the phase distribution of mold slag in the slag channel of the continuous casting mold is shown to regulate the local area where the heat transfer is too large in the continuous casting of high manganese steel. The peak current of the electric pulse is 60A, the output voltage is 32V, and the frequency At 30Hz, the duty cycle is 0.4, the electrification time is 8min, and the electrode is 13mm away from the inner wall of the crystallizer.

[0066] After observation and sampling inspection, the cracks of the slab in this part are significantly reduced, the average thickness of the slag film is 3.3mm, the distribution is uniform, the crystallization rate is 90%, the grain size becomes larger, and the heat flow in this part decreases by 146KW / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com