Multi-station intelligent fiber laser welding machine work platform

A working platform and intelligent optical fiber technology, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve problems such as impact, a large amount of smoke and welding slag, increase production costs, etc., and achieve simple structure, convenient operation, and practicality high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

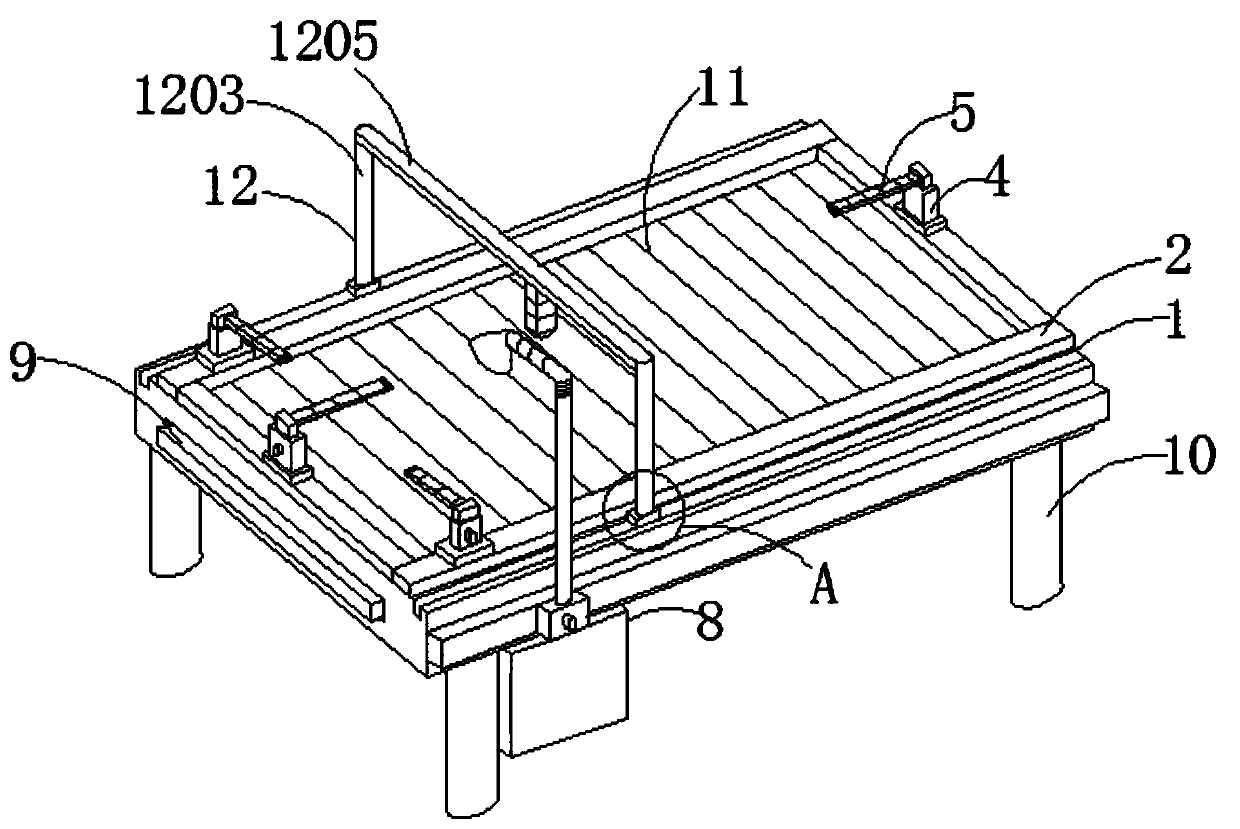

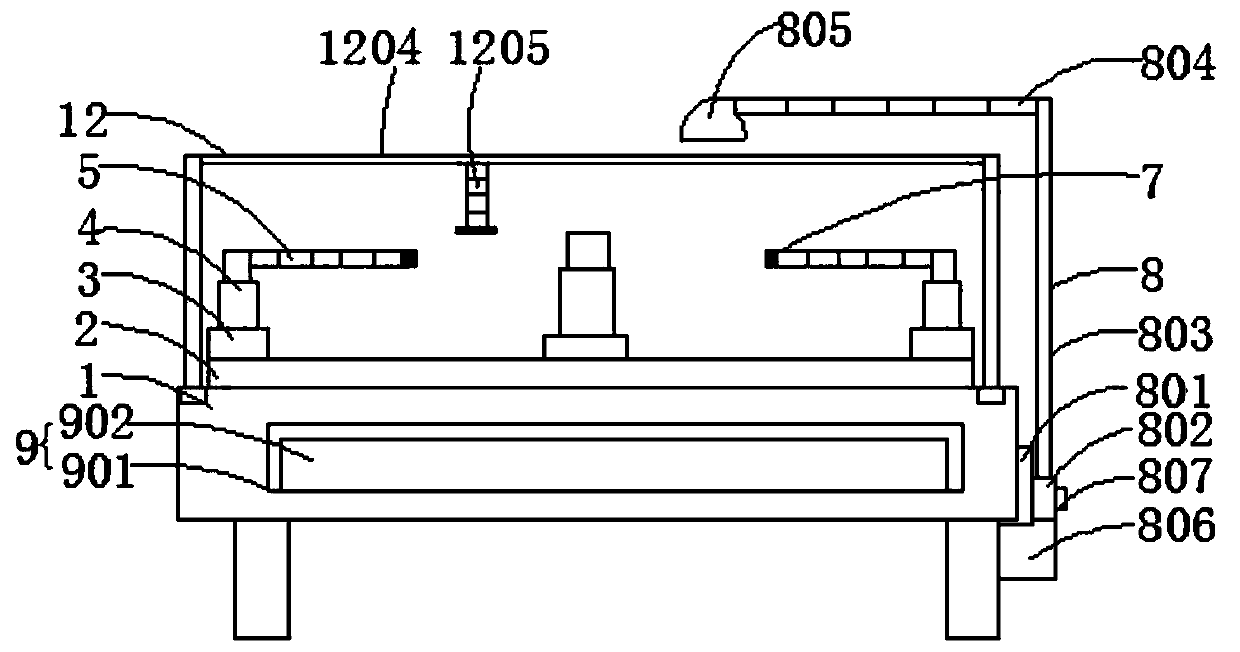

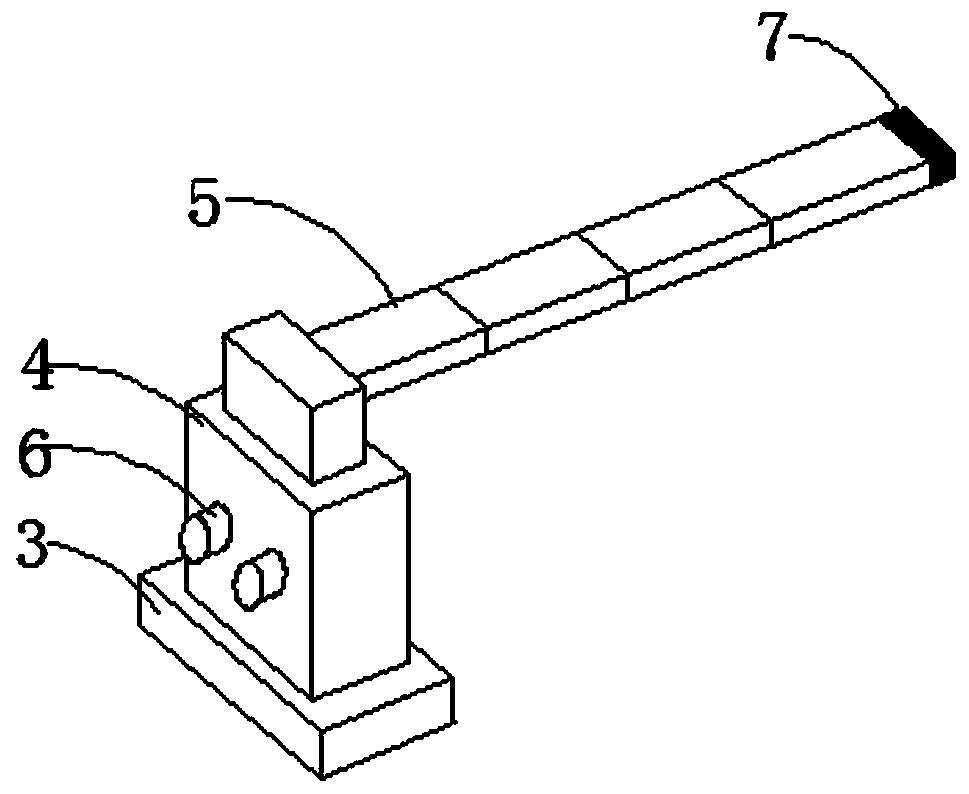

[0025] like Figure 1-3 As shown, a multi-station intelligent optical fiber laser welding mechanical working platform includes a working platform body 1, four rails 2 are arranged around the upper end of the working platform body 1 along the edge, and a slider 3 is slidably installed on each rail 2, The upper end of the slider 3 is vertically equipped with a support plate 4, and the upper end of the support plate 4 is horizontally provided with a telescopic rod 5 on one side of the working platform body 1, and a control switch 6 for controlling the length of the telescopic rod 5 is installed on the side wall of the support plate 4 , the free end of the telescopic rod 5 is provided with a rubber pad 7, one side of the working platform body 1 is provided with a smoke absorbing device 8, the inside of the working platform body 1 is provided with a welding slag collecting device 9, and the four corners of the lower end of the working platform body 1 A support column 10 is installe...

Embodiment 2

[0028] like Figure 1-3 As shown, a multi-station intelligent optical fiber laser welding mechanical working platform includes a working platform body 1, four rails 2 are arranged around the upper end of the working platform body 1 along the edge, and a slider 3 is slidably installed on each rail 2, The upper end of the slider 3 is vertically equipped with a support plate 4, and the upper end of the support plate 4 is horizontally provided with a telescopic rod 5 on one side of the working platform body 1, and a control switch 6 for controlling the length of the telescopic rod 5 is installed on the side wall of the support plate 4 , the free end of the telescopic rod 5 is provided with a rubber pad 7, one side of the working platform body 1 is provided with a smoke absorbing device 8, the inside of the working platform body 1 is provided with a welding slag collecting device 9, and the four corners of the lower end of the working platform body 1 A support column 10 is installe...

Embodiment 3

[0032] like figure 1 , 2As shown in and 4, a multi-station intelligent optical fiber laser welding mechanical working platform includes a working platform body 1, four rails 2 are arranged around the upper end of the working platform body 1 along the edge, and a slide block is slidably installed on each rail 2 3. A support plate 4 is vertically installed on the upper end of the slider 3, and a telescopic rod 5 is installed horizontally on the side of the upper end of the support plate 4 facing the working platform body 1, and a control device for controlling the length of the telescopic rod 5 is installed on the side wall of the support plate 4. The switch 6, the free end of the telescopic rod 5 is provided with a rubber pad 7, one side of the working platform body 1 is provided with a smoke absorbing device 8, the inside of the working platform body 1 is provided with a welding slag collecting device 9, and the lower end of the working platform body 1 has four A support colu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com