Flexible welding workstation of rectangular flange intelligent robot

A technology of intelligent robots and welding workstations, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity, difficult to guarantee product quality, low production efficiency, etc., to reduce labor intensity, size Guaranteed precision and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The automatic positioning flexible welding jig for rectangular flanges of the present invention will be described in detail below in conjunction with the accompanying drawings.

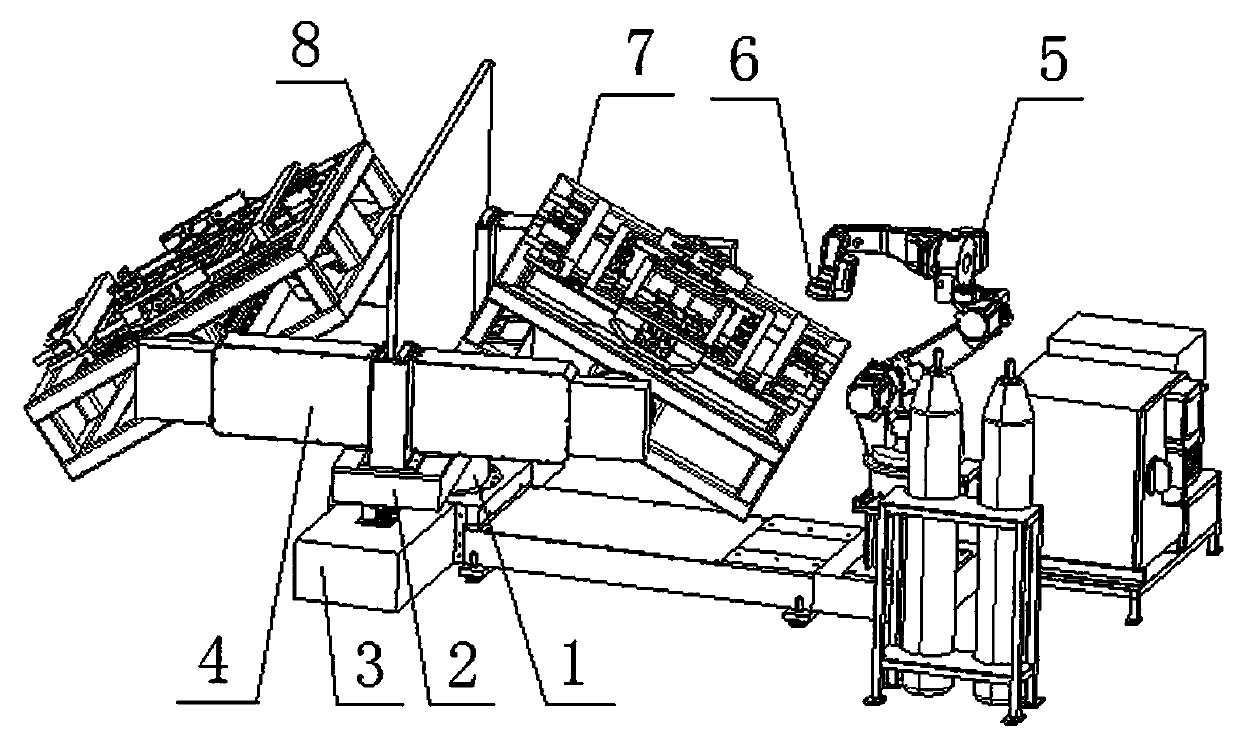

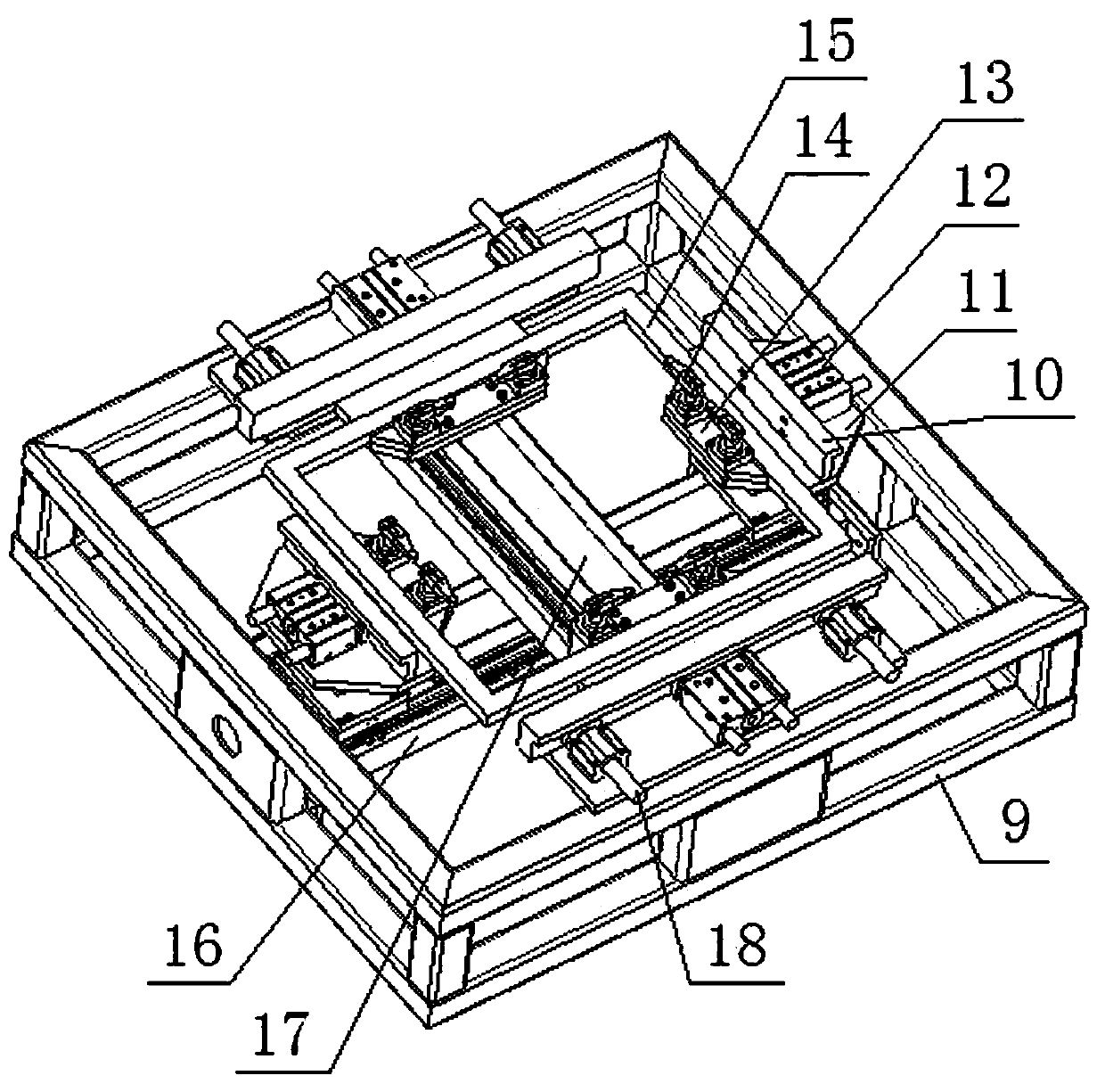

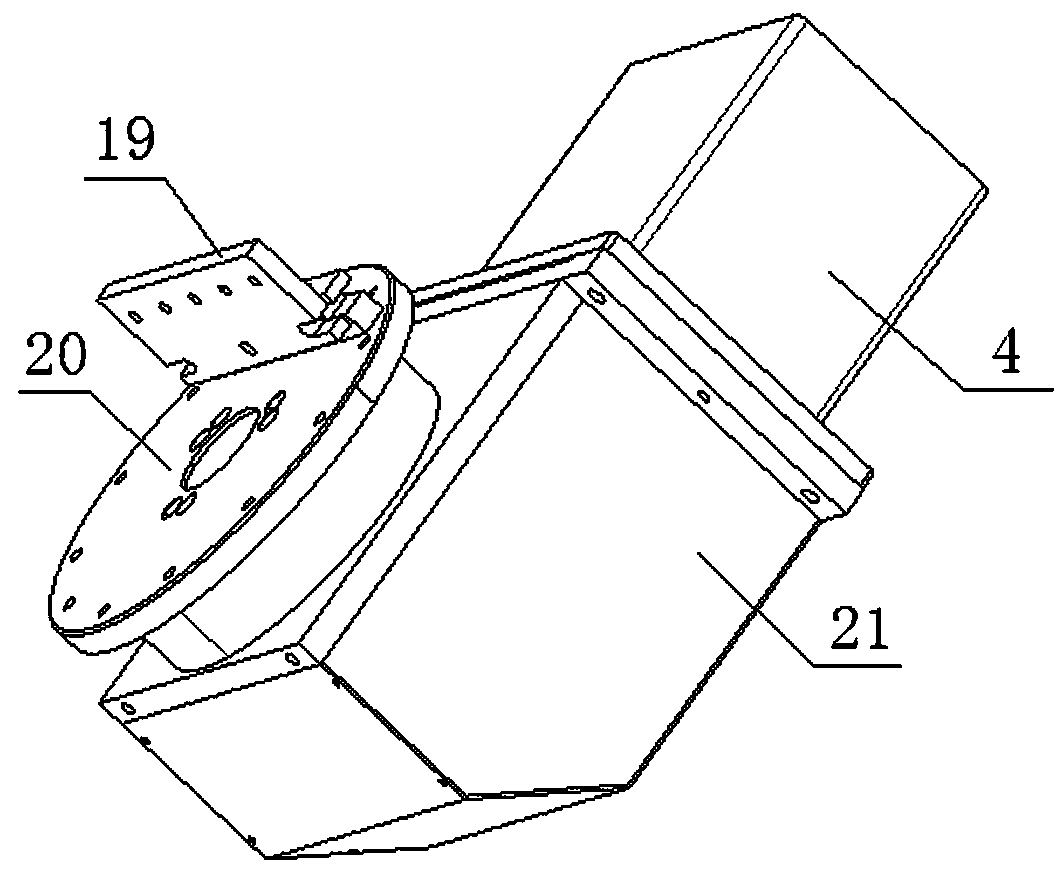

[0015] see figure 1 and figure 2 , the rectangular flange intelligent robot flexible welding workstation of the present invention comprises a rotary worktable and a welding robot located beside the rotary workbench. Among them, the rotary workbench is provided with a workbench rotation axis 1 on the base 3, the workbench rotation axis 1 is driven to rotate by the servo motor through the reducer, and the workbench rotation axis 1 is fixed on the workbench rotation axis 1. Rotating rotating beam 2, the midpoint of the rotating beam 2 is connected and fixed with the workbench rotating shaft 1, and the rotating beam end arms 4 are respectively symmetrically arranged at both ends of the rotating beam 2, and the midpoint of the rotating beam end arm 4 is connected with the rotating beam 2. Connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com