Telescopic anti-rolling plant

A device, the technology of anti-roll plate, is applied to the equipment to reduce the movement of the ship, the equipment to increase the stability of the ship, and the use of hydrofoils to reduce the movement of the ship on the surrounding water surface. Improve efficiency and application range, ensure sealing and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

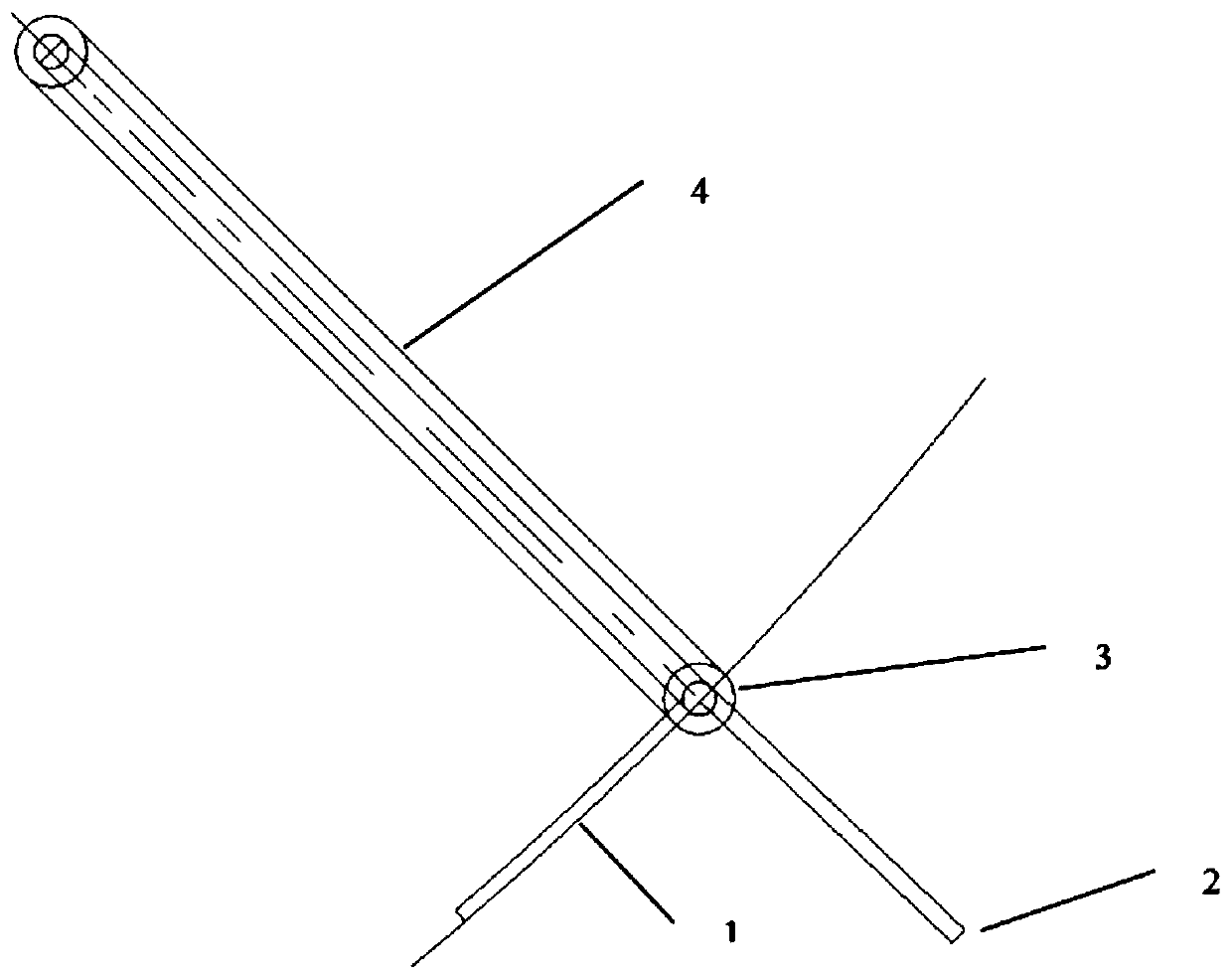

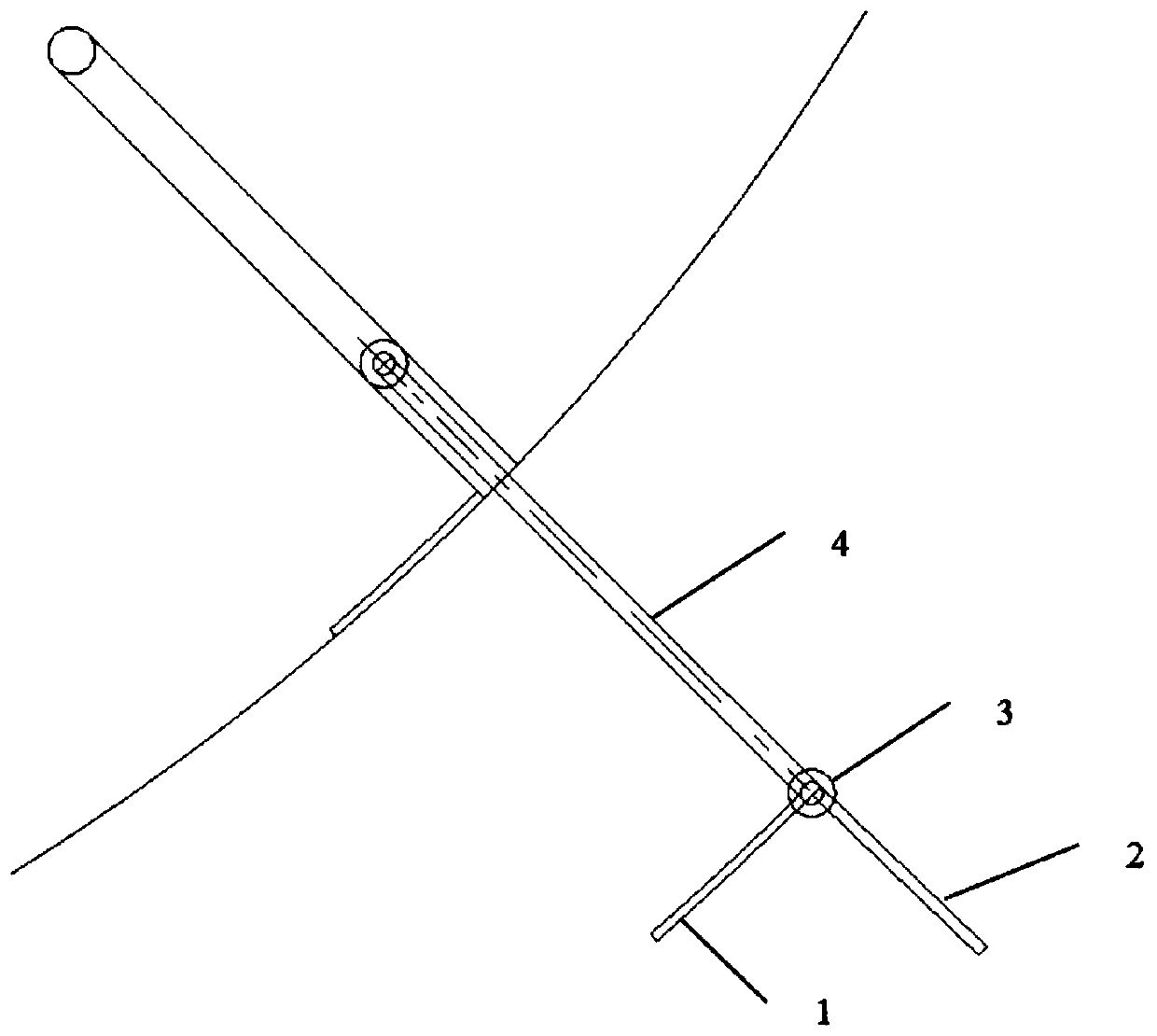

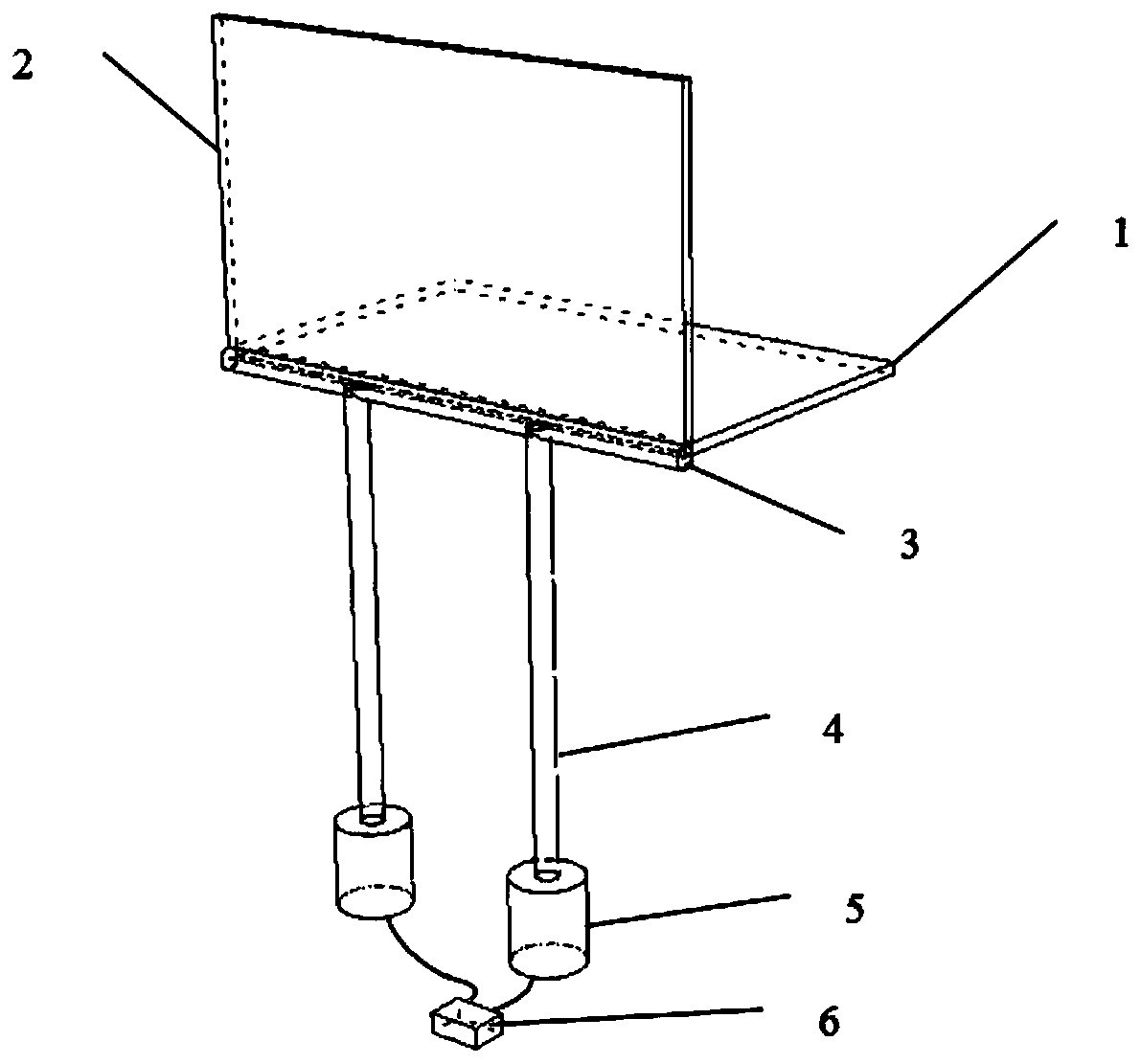

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] Such as image 3 As shown, a set of anti-rolling devices adopted in the present invention includes an outer shaft 3 on which an arc-shaped anti-rolling plate 1 and a rectangular anti-rolling plate 2 are connected. One end of the telescopic control rod 4 is connected to the outer shaft 3 , and the other end is connected to the hydraulic power unit 5 , and the hydraulic power unit 5 is connected to the control system 6 . The control system 6 controls the operation of the hydraulic power unit 5 according to the instruction signal, drives and controls the expansion and contraction of the telescopic control rod 4, thereby controlling the position of the anti-rolling plate relative to the hull.

[0026] Such as image 3 As shown, the arc-shaped anti-rolling plate 1 is designed according to the shape of the bilge of the hull to ensure that it fits t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com