Treatment process for microorganisms of drilling solid waste

A solid waste and microbial treatment technology, applied in biological water/sewage treatment, metallurgical wastewater treatment, water/sludge/sewage treatment, etc., can solve the problems of poor mobility, strong ability, good effect, easy to decompose nutrients The effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] As a preferred embodiment of the present invention, it discloses a microbial treatment process for drilling solid waste. First, strain cultivation: microbial degrading bacteria are cultivated and domesticated to obtain degrading strains; secondly, preparing the drilling solid waste mixture: by volume Ratio, 0.5-1 part of soil, 0.001-0.005 part of bacteria and 0.5-1.5 part of rice bran are added to 1 part of drilling solid waste to form a mixture of drilling solid waste, wherein the moisture content of the soil is 35 % or less; Then, implement the treatment process according to the following steps:

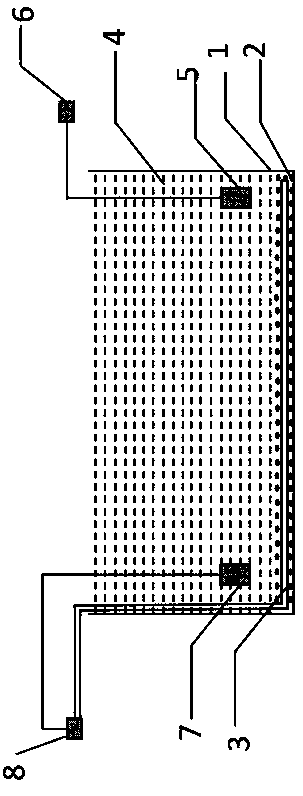

[0027] a. Prepare a tank for treating drilling solid waste microorganisms;

[0028] b. Lay multiple horizontal pipes on the bottom of the tank, and perforate the horizontal pipes;

[0029] c, laying cobblestones at the bottom of the jar, the laying thickness of the cobblestones is greater than the pipe diameter of the horizontal pipe;

[0030] d. Laying the prepared drilli...

Embodiment 2

[0034] As another preferred embodiment of the present invention, it discloses a drilling solid waste microbial treatment process, first of all, strain cultivation: microbial degradation bacteria are cultivated and domesticated to obtain degrading strains; secondly, the drilling solid waste mixture is prepared: In terms of volume ratio, add 0.5-1 part of soil, 0.001-0.005 part of bacteria and 0.5-1.5 part of rice bran to 1 part of drilling solid waste to form a mixture of drilling solid waste, wherein the moisture content of the soil Below 35%; Then, implement the treatment process according to the following steps:

[0035] a. Prepare a tank for treating drilling solid waste microorganisms;

[0036] b. Lay multiple horizontal pipes on the bottom of the tank, and perforate the horizontal pipes;

[0037] c, laying cobblestones at the bottom of the jar, the laying thickness of the cobblestones is greater than the pipe diameter of the horizontal pipe;

[0038] d. Laying the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com