Nylon composite for fuel tank and preparation method of nylon composite

A technology of nylon composite materials and fuel tanks, applied in the field of nylon products, can solve problems such as unadaptable, unsatisfactory, and difficult to achieve fuel permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

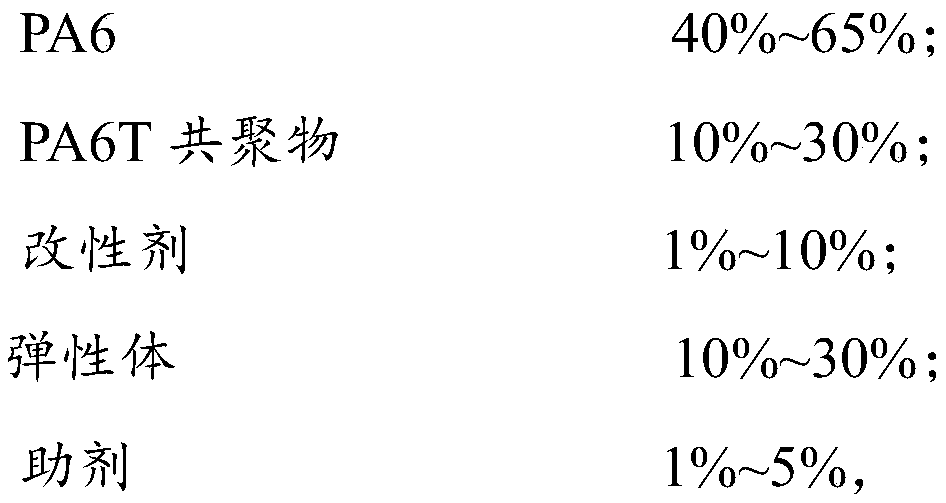

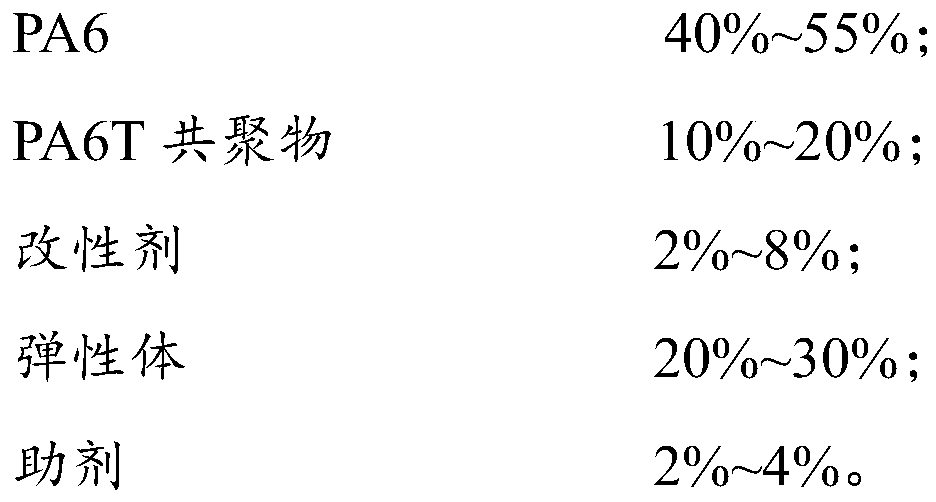

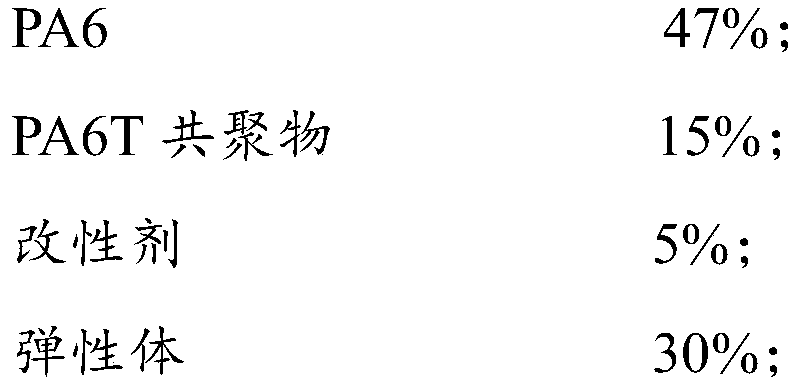

[0025] A kind of nylon composite material for fuel tank, its preparation raw material comprises the following components by weight percentage:

[0026]

[0027] PA6T copolymer is PA6T and PA6 copolymer that the content of PA6T is 80%, modifier is HDPE, and elastomer is SEBS, and auxiliary agent is phosphite antioxidant, calcium stearate and CAV102 with weight ratio 1: 1:1 mixture.

[0028] The preparation method of the nylon composite material for this fuel tank is:

[0029] 1) Add PA6, PA6T copolymer, modifier, and elastomer into a high-speed mixer, drop in white mineral oil, and mix for 2 minutes;

[0030] 2) Add the additives into the high-speed mixer and mix for 2 minutes to obtain the blended material;

[0031] 3) Add the blended material obtained in step 2) into a twin-screw extruder, and after mixing, melt and extrude at a temperature of 265°C and a rotation speed of 150r / min;

[0032] 4) After cooling, cut into pellets, sieve and pack.

[0033] The components an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com