Permanent antistatic spray-free ABS material

An ABS material, spray-free technology, applied in the direction of conductive paint, coating, etc., to improve the affinity and maintain the effect of antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

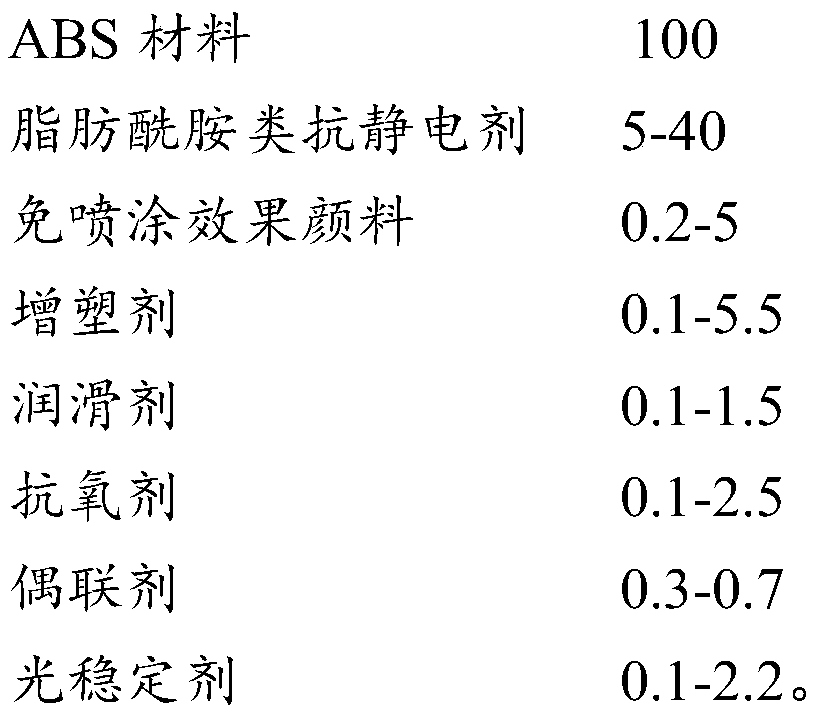

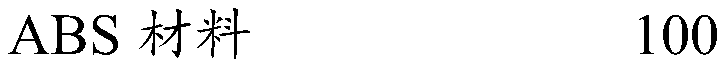

Method used

Image

Examples

Embodiment 1

[0034] 1000g of ABS material was weighed, the content of styrene in the ABS material was 50% by weight, the content of acrylonitrile was 25%, the content of butadiene was 20%, and the melt flow rate was 20g / 10min. The ABS material was dried in an oven at 80° C. for 2 hours, and then used.

[0035] Weigh 100g of artificial mica pearlescent glittering pigment with a particle size of 100 μm, and set aside. Weigh 2g of KH550 coupling agent and dilute with 25g of absolute ethanol. Mix the diluted coupling agent with 100 g of the artificial mica pearlescent scintillation pigment, and then place it in a high-speed mixer to stir evenly to complete the modification of the pearlescent scintillation pigment.

[0036] Weigh 150g ethoxylated alkylamine, 2g plasticizer DOP, 1g polyethylene wax, 1g antioxidant KY-1010, 1g light stabilizer UV-326. Add the weighed ABS material, the modified pearlescent flashing pigment and the weighed ethoxylated alkylamine, plasticizer DOP, polyethylene wax...

Embodiment 2

[0040] 1000g of ABS material was weighed, the content of styrene in the ABS material was 50% by weight, the content of acrylonitrile was 25%, the content of butadiene was 20%, and the melt flow rate was 20g / 10min. The ABS material was dried in an oven at 80° C. for 2 hours, and then used.

[0041] Weigh 100g of silica pearlescent scintillation pigment with a particle size of 100 μm, and set aside. Weigh 2g of KH550 coupling agent and dilute with 25g of absolute ethanol. Mix the diluted coupling agent with the 100 g of the silica pearlescent scintillation pigment, mix evenly, and then place it in a high-speed mixer to stir evenly to complete the modification of the pearlescent scintillation pigment.

[0042]Weigh 250g of ethoxylated alkylamine, 2g of plasticizer DOP, 1g of polyethylene wax, 1g of antioxidant KY-1010, and 1g of light stabilizer UV-326. Add the weighed ABS material, the modified pearlescent flashing pigment and the weighed ethoxylated alkylamine, plasticizer DO...

Embodiment 3

[0046] 1000g of ABS material was weighed, the content of styrene in the ABS material was 50% by weight, the content of acrylonitrile was 25%, the content of butadiene was 20%, and the melt flow rate was 20g / 10min. The ABS material was dried in an oven at 80° C. for 2 hours, and then used.

[0047] Weigh 100 g of aluminum silicate pearlescent glittering pigment with a particle size of 100 μm, and set aside. Weigh 2g of KH550 coupling agent and dilute with 25g of absolute ethanol. Mix the diluted coupling agent with the 100 g of aluminum silicate pearlescent scintillation pigment, mix evenly, and then place it in a high-speed mixer to stir evenly to complete the modification of the pearlescent scintillation pigment.

[0048] Weigh 350g ethoxylated alkylamine, 2g plasticizer DOP, 1g polyethylene wax, 1g antioxidant KY-1010, 1g light stabilizer UV-326. Add the weighed ABS material, the modified pearlescent flashing pigment and the weighed ethoxylated alkylamine, plasticizer DOP,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com