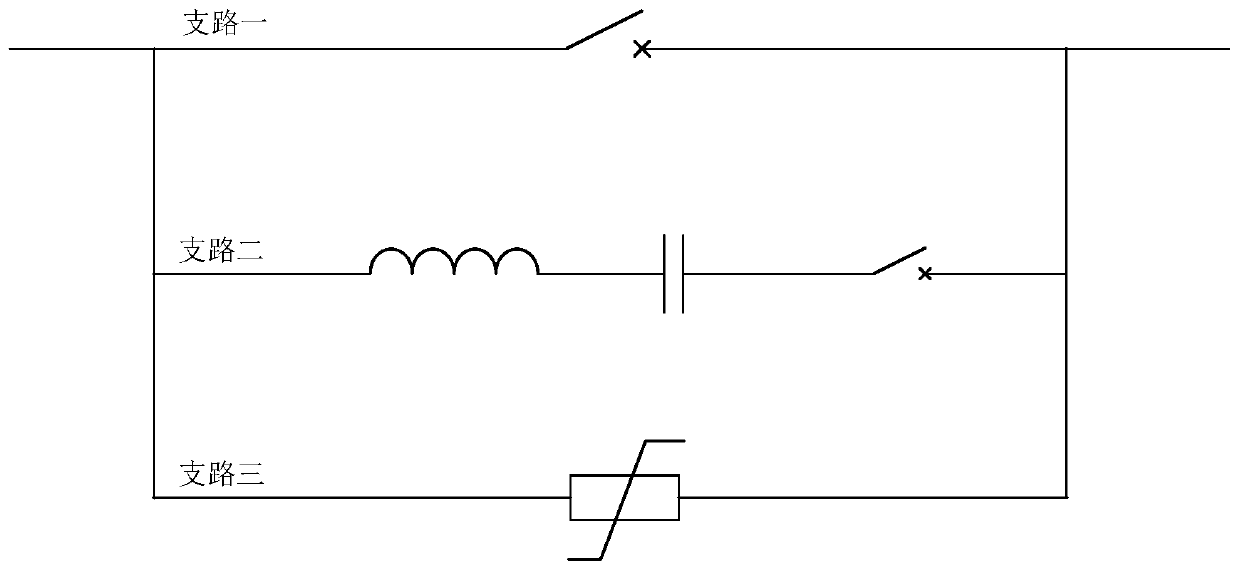

Double-coil contact structure of vacuum arc-extinguishing chamber in mechanical high-voltage DC circuit breaker

A technology of vacuum interrupter and high-voltage direct current, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems such as difficult to increase the magnetic field, achieve simple structure, long electrical life of contacts, and save raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

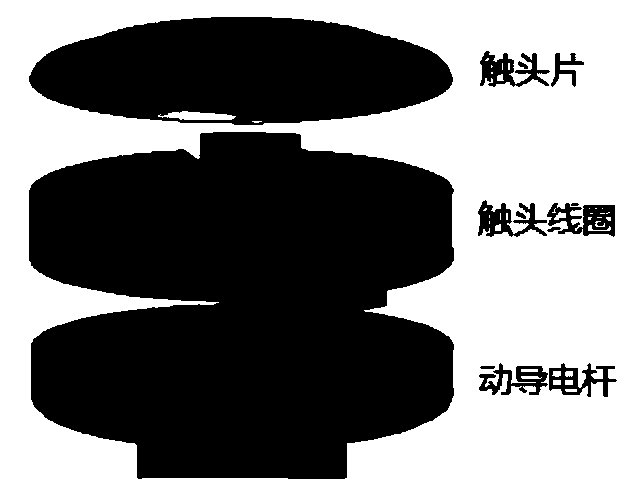

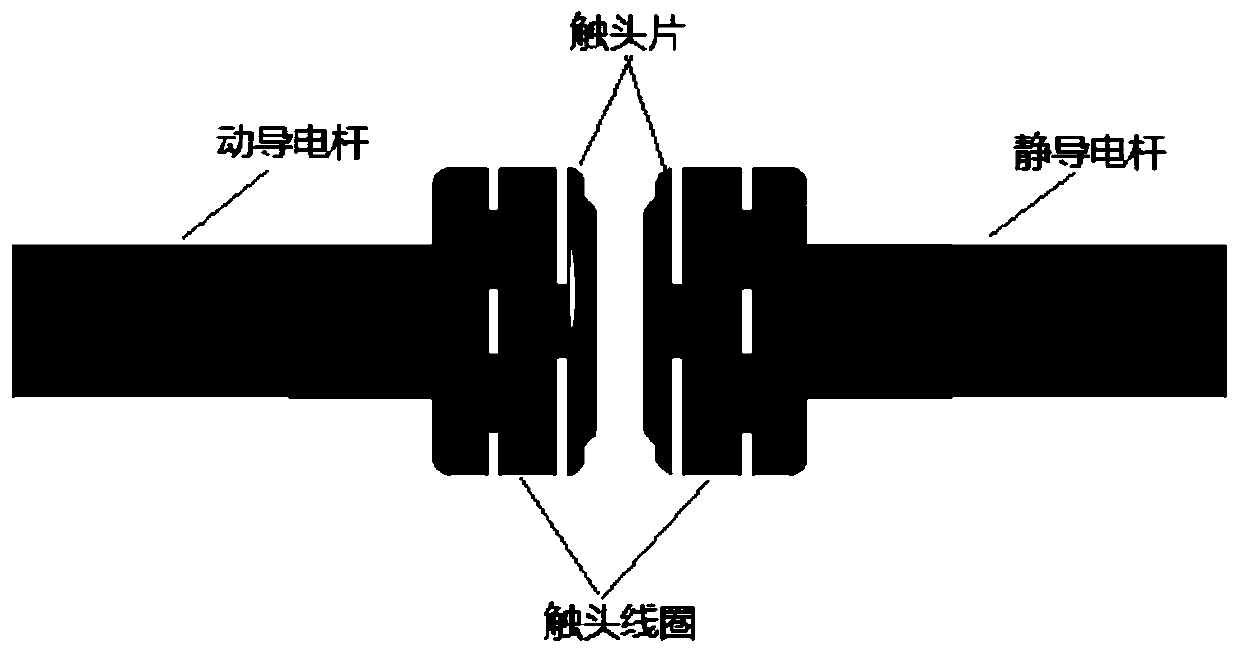

[0014] The double-coil contact structure of the vacuum interrupter in the mechanical high-voltage DC circuit breaker of the present invention is as follows: Figure 4 and Figure 5 shown. Consisting of two identical contacts, each contact includes an unclosed ring coil, an insulating ring gasket and a ring contact with a gap. The conductive rod is a T-shaped cylindrical rod, and the diameter of the big head of the conductive rod is the same as the outer diameter of the ring coil and the ring contact. There is a metal protrusion on the round surface of the big head of the conductive rod and the ring coil. Surface, ring coil and ring contact are stacked and connected in sequence. Except for the raised part, the rest of the connecting surface is supported by an insulating ring gasket made of polytetrafluoroethylene or a higher-strength insulating material. The metal protrusion makes The conductive rod, the ring coil and the ring contact are electrically connected, and the best ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com